[4] DISASSEMBLY/ASSEMBLY

[4]-8. Engine

R

epair

P 1

4

/

19

DISASSEMBLING

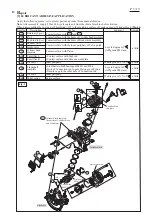

Fig. 48

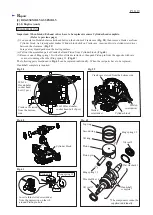

Fig. 49

(1) Remove Clutch complete and Clutch drum. Refer to

[4]-3

.

(2) Remove Flywheel. Refer to

[4]-4

. If necessary, remove Ignition coil.

(3) Loosen five M6x25 Hexalobular socket head bolts, then remove Cutting arm from Cylinder block complete. (

Fig. 48

)

(4) Remove Exhaust muffler from Cylinder block complete.

Note

: Although Spark arrester can be removed from Exhaust muffler, it is not permitted to replace Spark arrester only

because it functions as the integrated part with Exhaust muffler.

(5) Remove Oil case from Cylinder block complete. (

Fig. 49

)

Note

: Unless you repair Exhaust valves, Cam lifters, and Rocker arms, do the following steps. It is not necessary to

remove Cylinder block from Crank case (

Fig. 49

)/ Carburetor from Cylinder block complete (Refer to

Fig. 34

.)

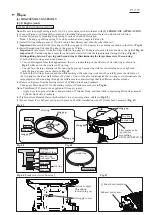

(6) Remove two M6x20 Hexalobular socket head bolts on the upper side of Exhaust muffler.

Remove two M5x25 Hexalobular socket head bolts then separate Rocker cover complete from Cylinder head

complete. (

Fig. 50

)

(7) Loosen Hose clamp then remove Suction line from Cylinder head complete. (Refer to

Fig. 41

)

(8) Remove Cylinder head complete from Cylinder block, then pull out two Push rods. (

Fig. 51

)

Note

: Do not failure to mix them up. It is recommend to distinguish Exhaust push-rod and Intake push-rod.

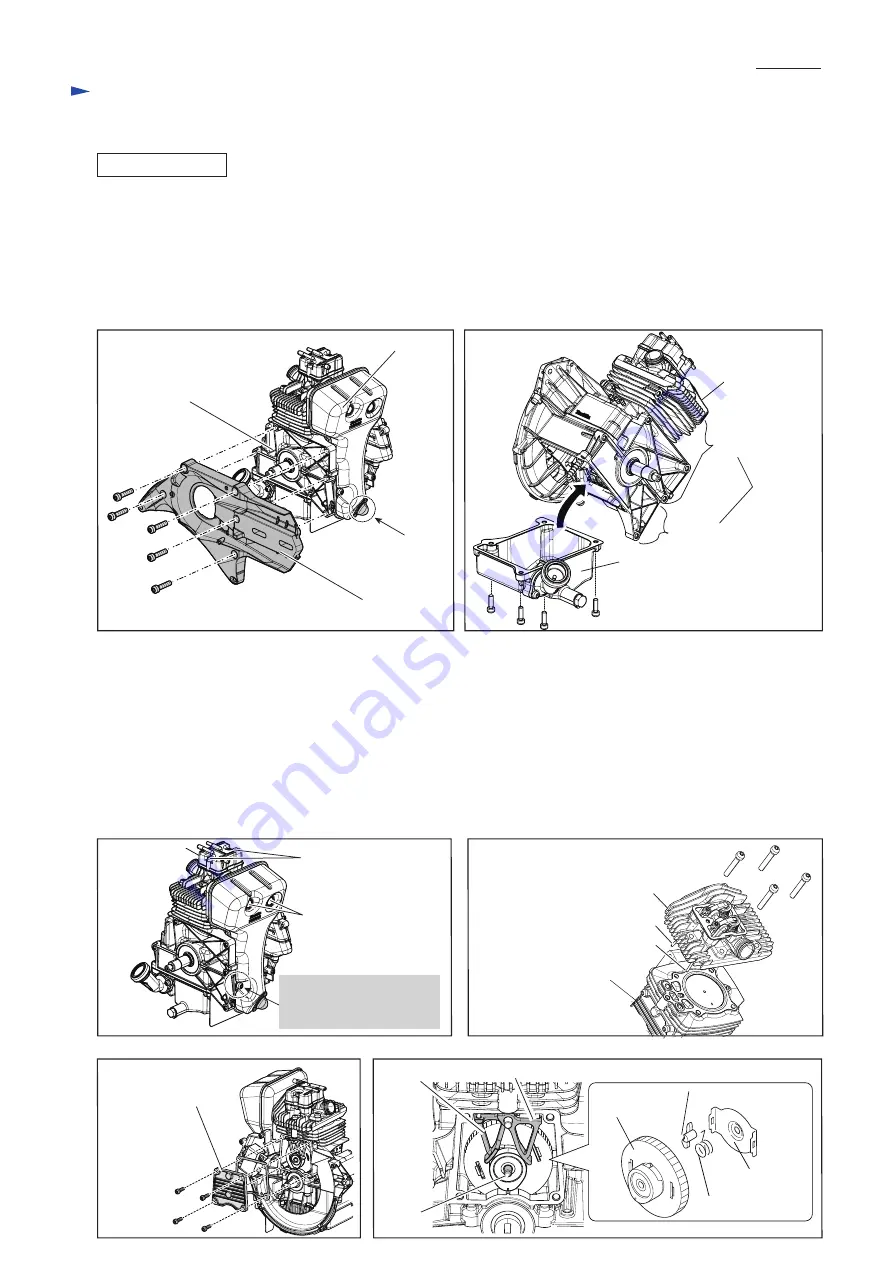

(9) Remove Cam gear cover (

Fig. 52

).

(10) Remove Cam lifter L and Cam lifter R. Then, remove Cam gear complete by pulling out Pin 5. (

Fig. 53

)

M5x16 Hexalobular

socket head bolt (4 pcs.)

M5x16

Hexalobular

socket head

bolt (4 pcs.)

Cam gear cover

M6x25 Hexalobular

socket head bolt (5 pcs.)

Oil case

Cylinder block

Crank case

Cylinder

block

complete

Cylinder head

complete

Cylinder block complete

Cutting arm

Exhaust

muffler

Spark arrester

Fig. 50

Fig. 51

Fig. 52

Fig. 53

M6x20 Hexalobular

socket head bolt

(2 pcs.)

Cylinder block

Cam lifter L

Pin 5

Cylinder head complete

M5x25 Hexalobular

socket head bolt

(2 pcs.)

M6x35 Hexalobular socket

head bolt (4 pcs.)

Rocker cover

complete

Push rod (for exhaust system)

Push rod (for intake system)

Cam lifter R

Cam gear assembly

Cam gear

complete

Fly weight

Cam gear plate

Torsion spring 9

Do not touch this M6x20

Hexalobular socket

head bolt.