16

ENGLISH

CAUTION:

Be careful not to injure yourself

with the cutter mounted on the protector.

NOTE:

The cutter on the protector keeps the nylon

cord best length for cutting.

For EM403MP and EM404MP

To install the protector extension, insert the protector

extension to the protector and then snap the clips on.

Make sure that the tabs on the protector extension fit

into the slots on the protector.

►

Fig.7:

1.

Protector (universal type)

2.

Clip

3.

Protector extension

4.

Cutter (inside)

5.

Slot

6.

Tab

To remove the protector extension from the protector,

unclasp the clips and pull the protector extension out.

CAUTION:

Make sure to push in the protec-

tor extension until it is fully inserted.

Otherwise

the protector extension may fall and result in personal

injury.

CAUTION:

Be careful not to injure your-

self with the cutter mounted on the protector

extension.

NOTE:

The cutter on the protector extension keeps

the nylon cord best length for cutting.

Installing the cutting tool

CAUTION:

Be sure to use genuine MAKITA

cutting tools.

CAUTION:

Be sure to remove the hex

wrench after installation.

NOTE:

When installing the cutting tool, turn the tool

upside down for ease of the procedure.

Installing the metal blade

For EM403MP and EM404MP

CAUTION:

When handling the metal blade,

always wear gloves and put the blade cover on

the blade.

CAUTION:

The outside diameter of the metal

blade must be 230 mm (9″). Never use any blades

larger than 230 mm (9″) in outside diameter.

CAUTION:

The metal blade must be well

polished, free of cracks or breakage. If the metal

blade hits against a stone during operation, stop

the motor and check the blade immediately.

CAUTION:

Polish or replace the metal blade

every three hours of operation.

CAUTION:

Always use the supplied

wrench(es) to remove or to install the blade.

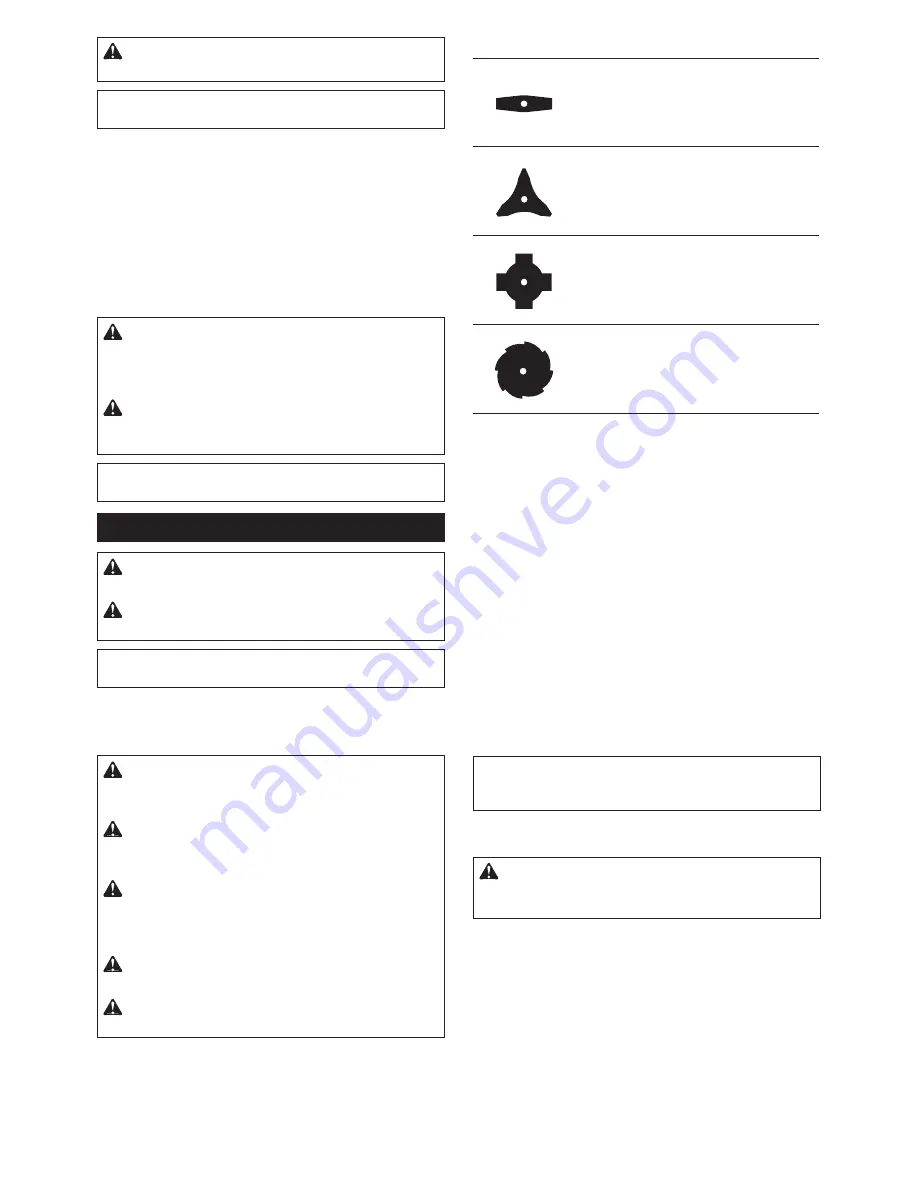

Applicable blade

Metal blade (2-tooth)

Metal blade (3-tooth)

Metal blade (4-tooth)

Metal blade (8-tooth)

1.

Insert the receive washer into the shaft.

2.

Insert the hex wrench through the hole in the gear

case to lock the shaft. Rotate the shaft until the hex

wrench is fully inserted.

3.

Mount the metal blade onto the receive washer.

4.

Install the clamp washer and cup, and then tighten

the nut securely.

Tightening torque: 16 - 23 N•m

5.

Remove the hex wrench.

►

Fig.8:

1.

Nut

2.

Cup

3.

Clamp washer

4.

Metal blade

5.

Receive washer

6.

Shaft

7.

Hex wrench

►

Fig.9:

1.

Socket wrench

2.

Hex wrench

3.

Tighten

Make sure that the arrows on the blade and protector

indicate the same way.

►

Fig.10

To remove the metal blade, follow the installation proce-

dure in reverse.

NOTE:

The resin part on the blade fastening nut

wears out in course of time. Replace the nut if there

appears any wear or deformation.

Installing the nylon cutting head

CAUTION:

If the nylon cutting head hits

against a stone during operation, stop the motor

and check the nylon cutting head immediately.

1.

Put the receive washer on the shaft.

2.

Insert the hex wrench through the hole in the gear

case.

3.

Screw the nylon cutting head onto the shaft.

4.

After installing nylon cutting head, remove the hex

wrench.

►

Fig.11:

1.

Nylon cutting head

2.

Receive washer

3.

Shaft

4.

Hex wrench

5.

Tighten

Summary of Contents for EM404MP

Page 4: ...Fig 12 3 1 2 Fig 16 1 750 mm 750 mm 100 300 mm Fig 17 1 Fig 18 Fig 19 4 ...

Page 5: ...3 m 80 mm 100 mm 䍺2 7 mm 䍺2 4 mm Fig 20 5 ...

Page 6: ...3 m 80 mm 100 mm 䍺2 7 mm 䍺2 4 mm Fig 21 6 ...

Page 7: ...3 m 80 mm 100 mm 䍺2 7 mm 䍺2 4 mm Fig 22 7 ...

Page 8: ...3 m 80 mm 100 mm 䍺2 7 mm 䍺2 4 mm Fig 23 8 ...

Page 9: ...4 5 m 100 mm 2 4 mm 2 4 mm Fig 24 9 ...

Page 10: ...Fig 25 Fig 26 10 ...