24

WARNING: When draining the fuel, be sure to stop the engine and confirm that the engine cools

down.

Just after stopping the engine, it may still hot with possibility of burns, inflammability and fire.

ATTENTION: When the machine is kept out of operation for a long time, drain up all fuel from the fuel

tank and carburetor, and keep it at a dry and clean place.

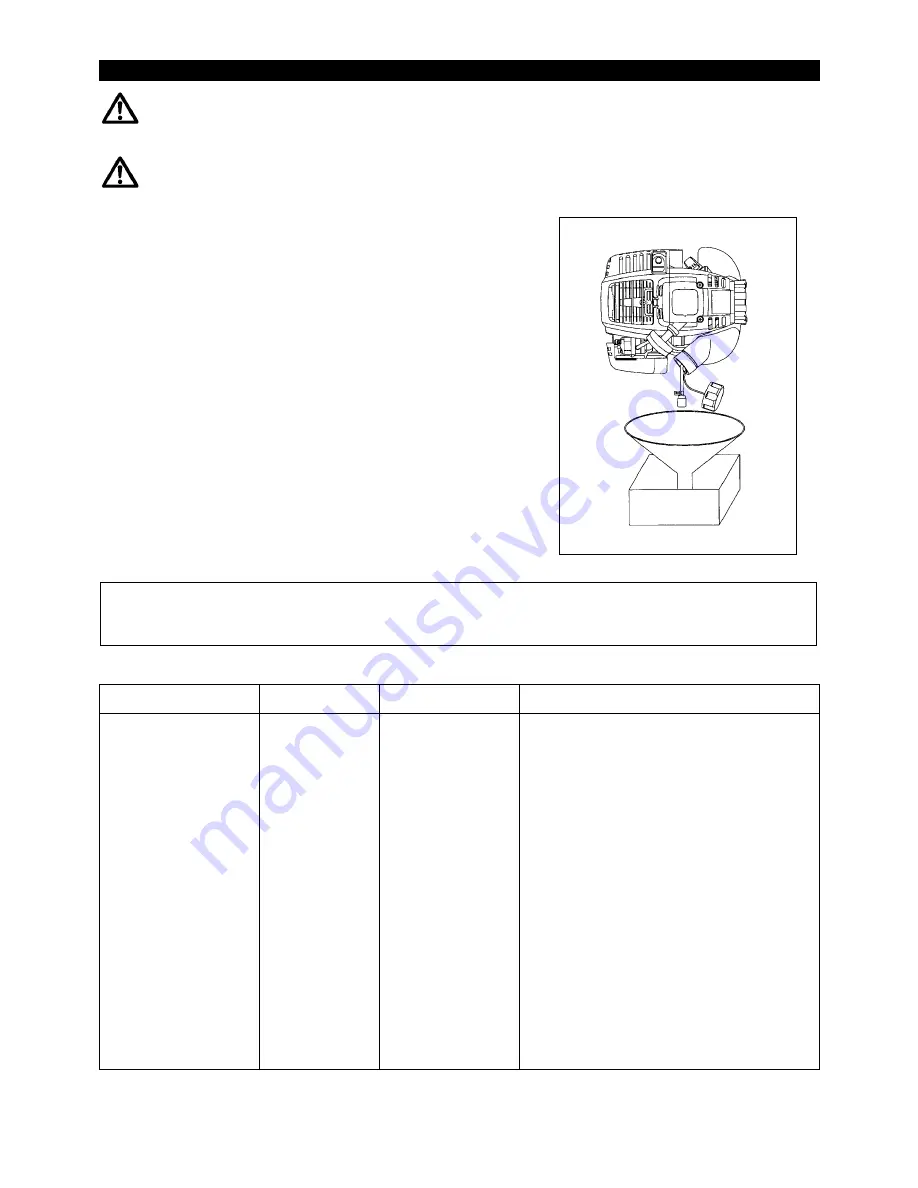

– Drain up fuel from the fuel tank and carburetor according to the following

procedure:

1) Remove the fuel tank cap, and drain fuel completely.

If there is any foreign matter remaining in the fuel tank, remove it

completely.

2) Pull out the fuel filter from the refill port using a wire.

3) Push the primer pump until fuel is drained from there, and drain fuel

coming into the fuel tank.

4) Reset the filter to the fuel tank, and securely tighten the fuel tank cap.

5) Then, continue to operate the engine until it stops.

– Remove the spark plug, and drip several drops of engine oil through the

spark plug hole.

– Gently pull the starter handle so that engine oil will spread over the engine,

and attach the spark plug.

– Attach the cover to the cutter blade.

– During storage, keep the rod horizontal or keep the machine upright with the

blade edge oriented upward. (In this case, pay full attention to prevent the

machine from falling.)

Never store the machine with the cutter blade edge oriented downward.

Lubricating oil may spill out.

– Keep the drained fuel in a special container in a well-ventilated shade.

㩷

㩷

Attention after long-time storage

– Before startup after long-time shutdown, be sure to replace oil (refer to P 20). Oil will deteriorate while the machine is kept out of

operation.

㩷

Fault location

Fault System

Observation

Cause

Engine not starting or with

difficulty

Ignition system

Ignition spark O.K.

Fault in fuel supply or compression system, mechanical

defect

No ignition spark

STOP-switch operated, wiring fault or short circuit, spark

plug or connector defective, ignition module faulty

Fuel supply

Fuel tank filled

Incorrect choke position, carburetor defective, fuel supply

line bent or blocked, fuel dirty.

Compression

No compression when

pulled over

Cylinder bottom gasket defective, crankshaft seals

damaged, cylinder or piston rings defective or improper

sealing of spark plug

Mechanical fault

Starter not engaging

Broken starter spring, broken parts inside of the engine

Warm start problems

Tank filled ignition spark

existing

Carburetor contaminated, have it cleaned

Engine starts but dies

Fuel supply

Tank filled

Incorrect idling adjustment, carburetor contaminated

Fuel tank vent defective, fuel supply line interrupted,

cable or STOP-switch faulty

Insufficient performance

Several systems

may simultaneously

be affected

Engine idling poor

Air filter contaminated, carburetor contaminated, muffler

clogged, exhaust duct in the cylinder clogged

㩷

STORAGE