PRODUCT

P 1/ 1

8

T

ECHNICAL INFORMATION

C

ONCEPT AND MAIN APPLICATIONS

S

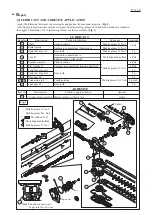

tandard equipment

O

ptional accessories

Models No.

EN4950H, EN4950HG

Description

Petrol Pole Hedge Trimmer

(Pole Hedge Trimmer

*1

for North and Central

American countries)

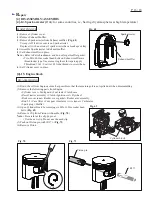

Model EN4950H is Pole hedge trimmer as a successor of PTR2500.

The advantages are as follows:

• 25.4cm³ 4-stroke engine with the multi-position engin

e lubrication system.

• 180° foldable hedge trimmer head for easy transport a

nd storage

• Built-in clutch to prevent unintentional blade motion

while the hedge

trimmer head is 180° folded

This product is also available with an E25 compatible e

ngine

as Model EN4950HG.

Blade cover ............................................................ 1

Socket wrench 10-16 ............................................. 1

Hex wrench 4 ......................................................... 1

Accessory bag ....................................................... 1

Oil set (inc. 80mL oil) ........................................... 1 (for some countries only)

Shoulder strap ........................................................ 1 (for some countries only)

Goggles .................................................................. 1 (for some countries only)

End cover set ......................................................... 1 (for some countries only)

Note:

The standard equipment for the tool shown ab

ove may vary by country.

Hedge trimmer head set

Shear blade assembly with End cover

Shear blade assembly without End cover

End cover set (for some countries only)

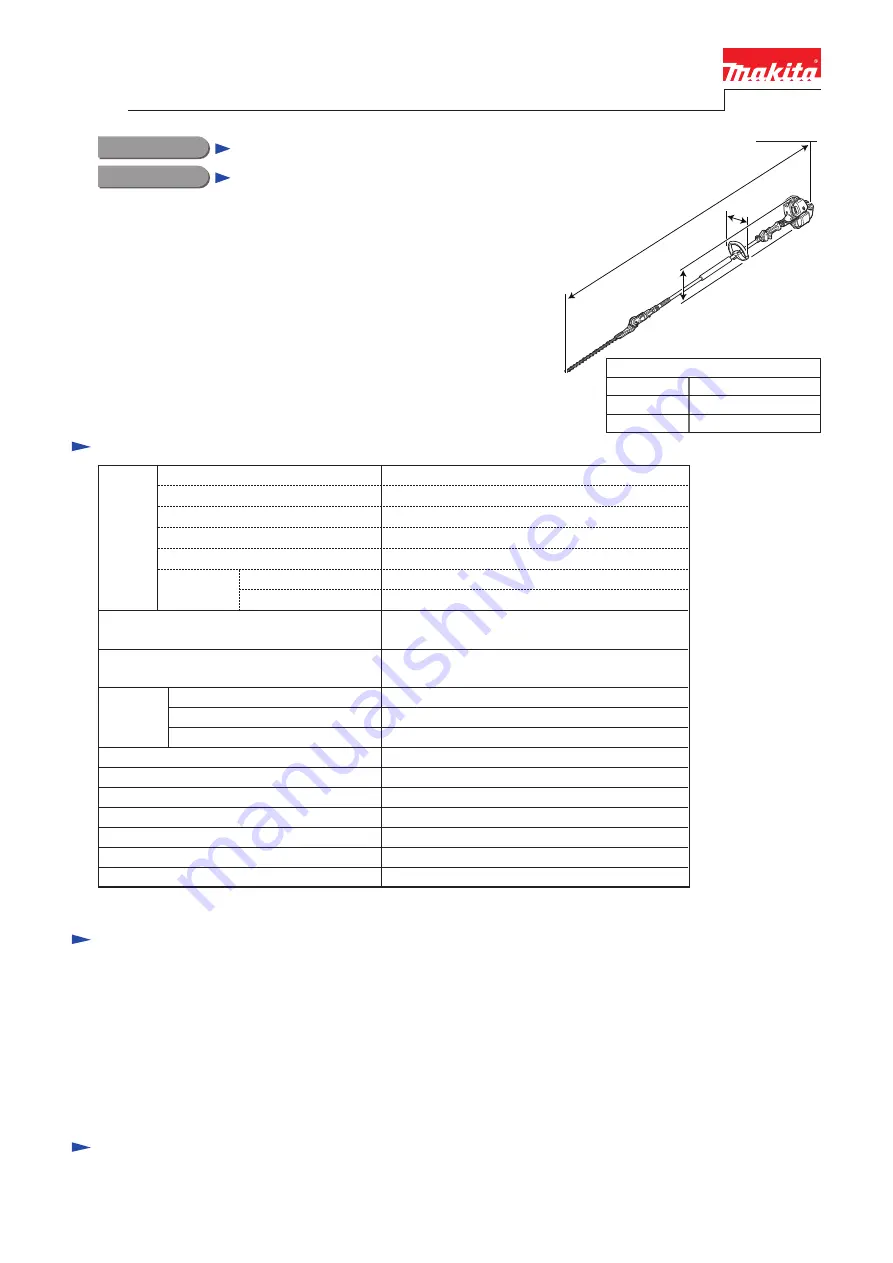

Dimensions: mm (")

Width (W)

Height (H)

Length (L)

242 (9-1/2)

2,550 (100-1/2)

241 (9-1/2)

S

pecification

6.9 (15)

Fuel tank capacity: L (US oz)

Engine

Displacement: cm³ (cu.in.)

Fuel

Type

Starting system

Engine oil

Carburetor

Net weight

*

2

: kg (lbs)

2,100

135° (45° tilt-up

*

1

, 90° tilt-down

*

1

)

7,000

10,000

Straight unleaded gasoline

0.6 (20.3)

Blade length: mm (")

490 (19-1/4)

25.4 (1.5)

Max. output: k

W (PS)

Max. torque: N.m

1.1 [at 5,500 min.

ˉ

¹]

0.77 (1.1) [at 7,000 min.

ˉ

¹]

4-stroke

Recoil starter with automatic decompression

SAE10W-30 oil

in the class SF or higher of API Classification

Diaphragm

Primer pump

Yes

Clutch

Yes

Strokes per minute: spm

Trimmer

blade

Angle adjustment range: degrees

Yes

Complia

nce with main exhaust emission regulations;

CA

RB Tie

r 3,EPA Phase 2, EU Stage 2

at max. output power

No load

Speed:

min.

ˉ

¹

=

rpm

Loop handle

Handle style

*1

from the hor

iz

ontal

pos

ition

*2

Dry weight

L

H

W