P

3

/ 1

8

R

epair

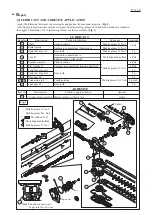

Item No.

Description

Lubricant

Amount

Amount

2g each

a little

a little

a little

a little

a little

Portion to lubricate

Item No.

Description

: Makita grease N. No.2

: ThreeBond 1215

: Makita grease N. No.1

: Molybdenum disulfide

Molybdenum disulfide

: Makita grease SG. No.0

256

256

286

286

3

Cam A

Reel

293

293

295

295

261

261

Shaft

Spiral bevel gear 9

Cam B

Spindle complete

3

Cylinder block assembly

Flat washer 36

Spiral bevel gear 11

Spiral bevel gear 12

Spur gear 24

Spur gear 43

Connecting rod

Surfaces to contact Gear housing and Joint

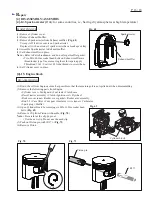

Apply the following lubricants to protect parts and product from unusual abrasion. (

Fig. 1

)

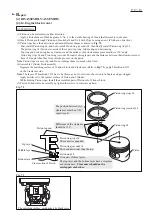

Once Engine is disassembled, remove oil/grease from the mating surface of Cylinder and Crankcase complete,

then apply ThreeBond 1215 to the mating surface for the reassembly. (

Fig. 1

)

[3] LUBRICANT AND ADHESIVE APPLICATION

LUBRICANT

Spline portions

Makita grease N. No.1

5 g

5 g

5 g

Makita grease N. No.2

Makita grease SG. No.0

Gear teeth

191

Spiral spring

Makita grease N. No.2

Surface to contact Reel / Starter case

Outside to contact Cam A

Spline portion on the inside

Spline portions

Crank portions

Gear teeth

Gear teeth

Portion to apply adhesive

Fig. 1

Makita grease N. No.2

ADHESIVE

299

302 304

303

116

116

299

302

303

304

270

270

5 g

5 g

191

Mating surface to Crank case

Starter case

Note

: The adhesive must not

be put into the oil route.