P

6

/ 1

8

R

epair

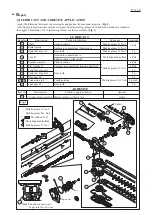

[4] DISASSEMBLY/ASSEMBLY

[4]-5. Trimmer head ass’y

(1) Remove Trimmer head ass’y from Pipe.

(2) Turn the machine upside down. Loosen six M4x16 Hex socket

head bolts and then remove Under cover. (

Fig. 12

)

Remove Plate and Gasket from the upper side (viewed from

Under cover installation side) in Gear housing complete.

(

Fig. 12

)

(3) Remove Connecting rod and Spur gear 43 from the upper side

in Gear housing complete. (

Fig. 13

)

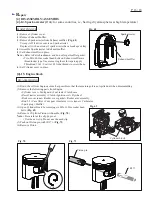

(4) After sliding Blade cover from the base of Shear blade ass’y,

loosen two M5x25 Hex socket head bolts and then remove

Seal and Shear blades. (

Fig. 14

)

Be careful to the shear blades.

Remove Connecting rod and Plate from Gear housing complete.

(

Fig. 14

)

Note

: Connecting rod and plate on the lower side in Gear housing

are the same as those on the upper side.

(5) Remove Retaining ring S-8 with 1R291 and separate Spur gear

24. Remove Retaining ring R-26 with 1R291. (

Fig. 15

)

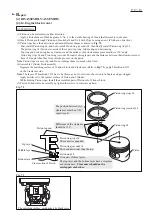

(6) Remove M6-10 Hex lock nut with Box driver 10-16 and

Wrench 4 supplied as standard equipment (

Fig. 16

), and

separate M6x85 Hex socket button head bolt from Joint.

Remove Gear housing section from Joint section. (

Fig. 17

)

M4x16 Hex socket head bolt (6 pcs.)

M5x25 Hex socket head bolt (2 pcs.)

Under

cover

Fig. 12

Fig. 14

Fig. 13

Fig. 15

Plate

Blade cover

Gasket

Connecting rod

Seal

Holder

Plate

Connecting rod

Retaining ring S-8

Retaining ring R-26

Spur gear 24

Spur gear 43

Fig. 16

Fig. 17

Wrench 4

Joint

M6-10 Hex lock nut

Box driver 10-16

Gear housing

complete

Gear housing

section

Coned disc spring 6

Joint section

Flat washer 6

M6x85 Hex socket

button head bolt

Flat washer 36

M6x85 Hex socket button head bolt

DISASSEMBLING