PRODUCT

C

ONCEPT AND MAIN APPLICATIONS

P 1/ 1

0

S

pecification

Model No.

EW1060H

Description

Engine Pump

Model EW1060H is 33.5cc 4-stroke engine pump to comply with

all major exhaust emission regulations in the world.

It features the same pumping capacity as the predecessor EPH1000,

but it is more cost effective than EPH1000.

This product is also available with nozzle and 8m delivery hose

as Model EW1060HX.

EW1060H

0.65 (22.0)

33.5 (2.0)

234 (9-1/4)

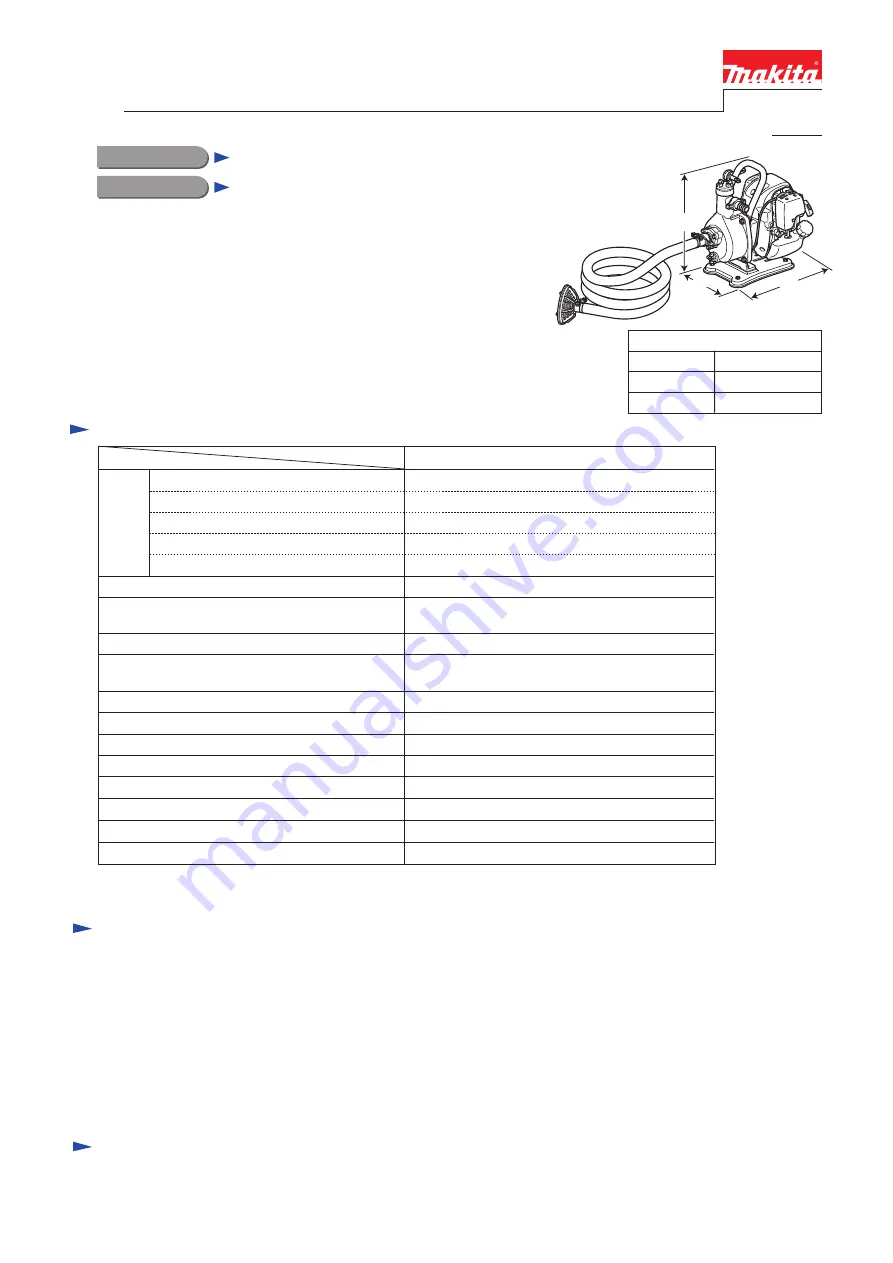

Dimensions

*

1

: mm (")

Width (W)

Height (H)

Length (L)

356 (14)

336 (13-1/4)

*1

without suction hose

T

ECHNICAL INFORMATION

H

L

W

Straight unleaded gasoline

*

2

Carburetor

Engine

Displacement: cm³ (cu.in.)

Fuel

Specifications

Model

Type

Net weight

*

3

: kg (lbs)

*2

Brazil: 25E gasoline

*3

Dry weight, without suction hose

In compliance with exhaust emission regulations:

CARB Tier 3, EPA Phase 2, EU Stage 2

Starting system

Max. suction head: m (ft)

Max. output: kW (PS)

Diaphragm

Suction & discharge diameter: mm (")

25.4 (1)

4-stroke

8.0 (26)

Max. pumping capacity: L/min (US oz/min)

130 (4,400)

Primer pump

Yes

Yes

7.3 (16.1)

1.07 (1.5) [at 7,000 min.

ˉ

¹]

1.35 [at 5,500 min.

ˉ

¹]

Max. torque: N·m

Speed at no load: min.

ˉ

¹ = rpm

7,000

Recoil starter, with mechanical decompression

Max. total head: m (ft)

45 (148)

Fuel tank capacity: L (US oz)

Engine oil

SAE10W-30 oil

in the class SF or higher of API Classification

S

tandard equipment

Note:

The standard equipment for the tool shown above may vary by country.

O

ptional accessories

Suction hose .......................... 1

Socket wrench ....................... 1

Hose coupling

....................... 2 (for some countries only)

Rapid type hose coupling ...... 2 (for some countries only)

1 inch NPT adapter ............... 1 (for Canada, Mexico, Colombia, Chile, Peru and Brazil only)

Hose band

............................. 3

Strainer ................................. 1

Delivery hose (8m)

............... 1 (for EW1060HX only)

Nozzle ................................... 1 (for EW1060HX only)

Rapid type Hose coupling set,

Coupling for water supply hose (with Hose band),

8m Delivery hose (with Nozzle),

1 inch NPT adapter