P

7

/

7

W

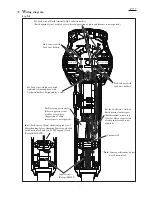

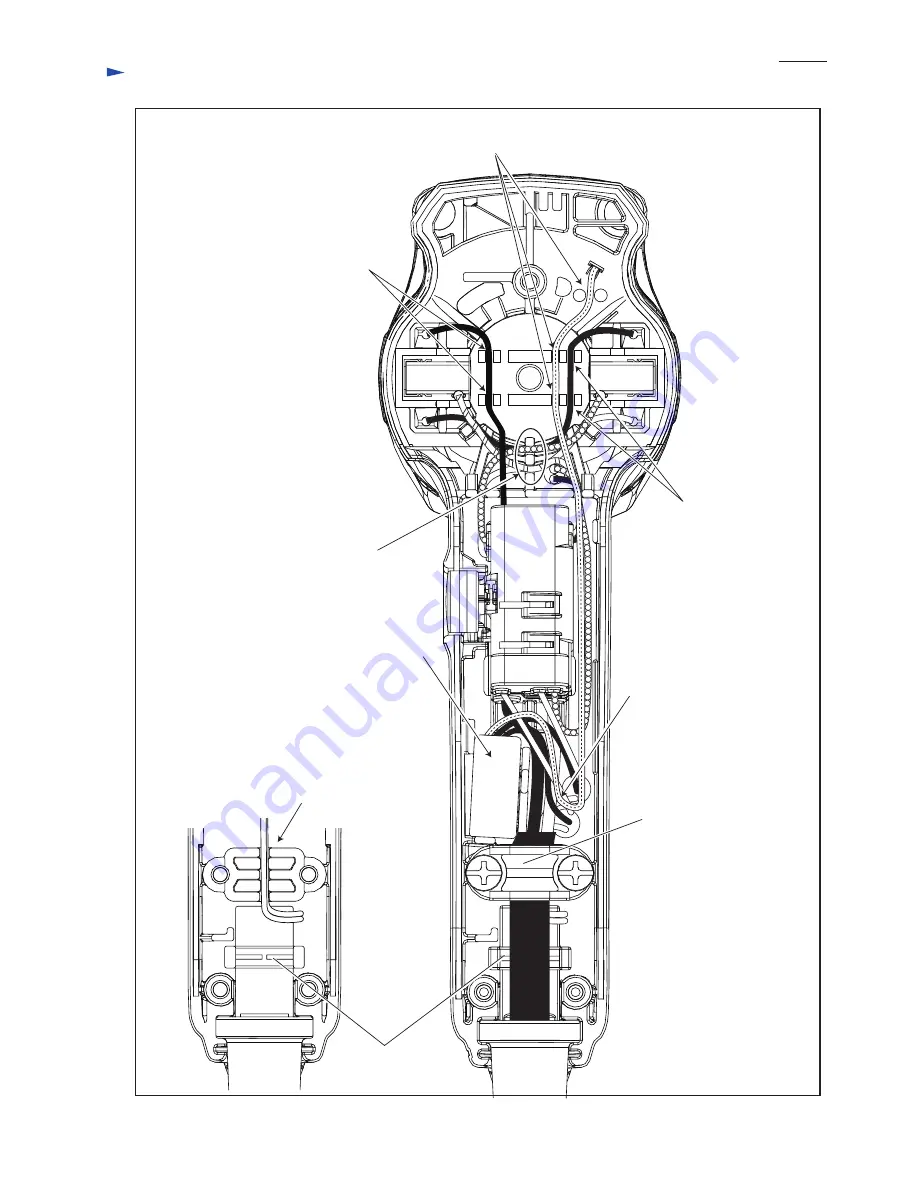

iring diagram

Fig. D-2

Light circuit

(Except FS4000)

Strain relief*

Insert Lead wires of Light circuit into grooves of

Motor housing before clamping Power supply cord

with Strain relief* and two 4x18 Tapping screws.

(Except FS4300TP)

Put the Lead wire’s slack of

Earth terminal in this space.

(Earth terminal is not used

for areas where suppression

of radio interference is not

required.)

Fix Lead wire of Earth terminal with Lead wire holders.

(Earth terminal is not used for areas where suppression of radio interference is not required.)

Fix Lead wires which are passed

right and left around here, with

Lead wire holders designated by a circle.

Put Noise suppressor here.

(Noise suppressor is not

used for areas where

suppression of radio

interference is not required.)

Brush holder

Brush holder

Fix Lead wire with

Lead wire holders.

Fix Lead wire with

Lead wire holders.

* Note: Some specifications do not

have Strain relief.