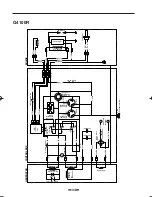

12. WIRING DIAGRAM

−

33

−

G2800R

V

+

-

REC1

Field Winding

Diode

Surge absorber

Auxiliary

Winding

for

condenser

AC Winding 1

AC Winding 2

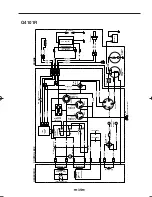

1.25Grn

1.25Brn

1.25Brn

0.75Y

0.75Y

2.0W

2.0R

2.0Blu

2.0Blk

2.0Blk

Voltmeter

No-fuse breaker

AC output

receptacle ( 120V

)

Condenser

Engine switch

1.25Blk

DC output

terminal

1.25Brn/W

1.25Or

Circuit breaker

Diode stack

Assy

2.0Grn

2.0Grn

Earth

(Ground) terminal

0.75Grn/Y

0.75Grn/Y

0.75Blk

Oil sensor

0.75Blk

Ignition coil

Spark plug

GRNERATOR

CONTROL BOX

ENGINE

DC Winding

W

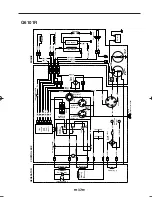

Wiring color cord

Blk

Black

Brn/W

Brown/White

R

Red

Blk/W

Black/White

Grn

Green

W

White

Blu

Blue

Grn/W

Green/White

Y

Yellow

LBlu

Light blue

Org

Orange

Brn

Brown

Gry

Gray

:

:

:

:

:

:

:

:

:

:

:

:

:

G28R-G61R 米国取説GU2016 05.1.26 11:15 AM ページ33