15 ENGLISH

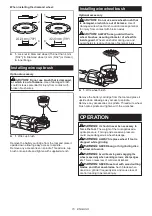

When installing the diamond wheel:

1

1

4

4

2

3

►

1.

Lock nut

2.

Diamond wheel (Thinner than 4 mm

(5/32″))

3.

Diamond wheel (4 mm (5/32″) or thicker)

4.

Inner flange

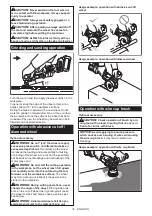

Installing wire cup brush

Optional accessory

CAUTION:

Do not use brush that is damaged,

or which is out of balance.

Use of damaged brush

could increase potential for injury from contact with

broken brush wires.

1

►

1.

Wire cup brush

Remove the battery cartridge from the tool and place it

upside down allowing easy access to spindle.

Remove any accessories on spindle. Thread wire cup

brush onto spindle and tighten with supplied wrench.

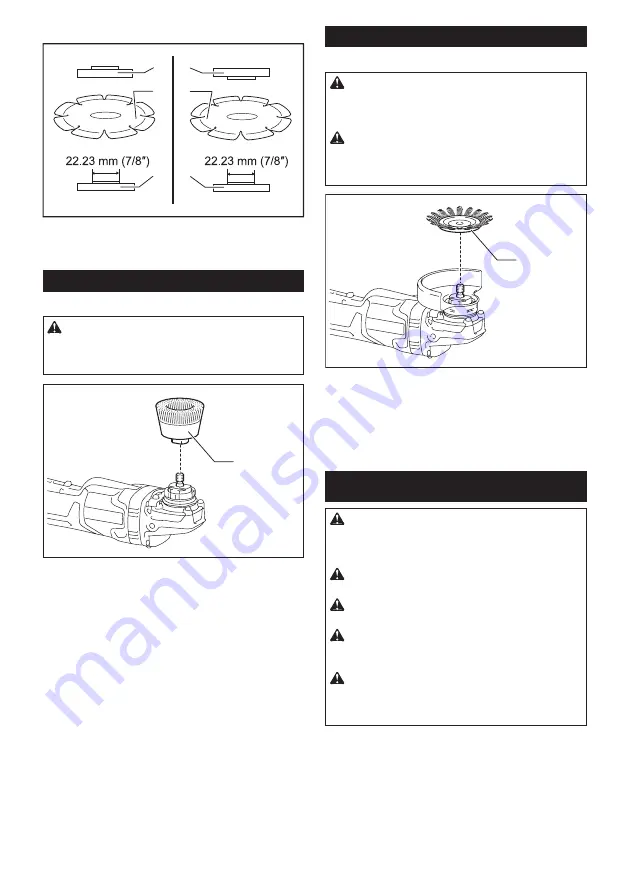

Installing wire wheel brush

Optional accessory

CAUTION:

Do not use wire wheel brush that

is damaged, or which is out of balance.

Use of

damaged wire wheel brush could increase potential

for injury from contact with broken wires.

CAUTION:

ALWAYS use guard with wire

wheel brushes, assuring diameter of wheel fits

inside guard.

Wheel can shatter during use and

guard helps to reduce chances of personal injury.

1

►

1.

Wire wheel brush

Remove the battery cartridge from the tool and place it

upside down allowing easy access to spindle.

Remove any accessories on spindle. Thread wire wheel

brush onto spindle and tighten with the wrenches.

OPERATION

WARNING:

It should never be necessary to

force the tool.

The weight of the tool applies ade-

quate pressure. Forcing and excessive pressure

could cause dangerous wheel breakage.

WARNING:

ALWAYS replace wheel if tool is

dropped while grinding.

WARNING:

NEVER bang or hit grinding disc

or wheel onto work.

WARNING:

Avoid bouncing and snagging the

wheel, especially when working corners, sharp edges

etc.

This can cause loss of control and kickback.

WARNING:

NEVER use tool with wood cutting

blades and other saw blades.

Such blades when

used on a grinder frequently kick and cause loss of

control leading to personal injury.

Summary of Contents for GA012G

Page 19: ...19 ...