9

ENGLISH

13.

If the tool is not used for a long period of time,

the battery must be removed from the tool.

14.

During and after use, the battery cartridge may

take on heat which can cause burns or low

temperature burns. Pay attention to the han-

dling of hot battery cartridges.

15.

Do not touch the terminal of the tool imme-

diately after use as it may get hot enough to

cause burns.

16.

Do not allow chips, dust, or soil stuck into the

terminals, holes, and grooves of the battery

cartridge.

It may cause heating, catching fire,

burst and malfunction of the tool or battery car

-

tridge, resulting in burns or personal injury.

17.

Unless the tool supports the use near

high-voltage electrical power lines, do not use

the battery cartridge near high-voltage electri-

cal power lines.

It may result in a malfunction or

breakdown of the tool or battery cartridge.

18.

Keep the battery away from children.

SAVE THESE INSTRUCTIONS.

CAUTION:

Only use genuine Makita batteries.

Use of non-genuine Makita batteries, or batteries that

have been altered, may result in the battery bursting

causing fires, personal injury and damage. It will

also void the Makita warranty for the Makita tool and

charger.

Tips for maintaining maximum

battery life

1.

Charge the battery cartridge before completely

discharged. Always stop tool operation and

charge the battery cartridge when you notice

less tool power.

2.

Never recharge a fully charged battery car-

tridge. Overcharging shortens the battery

service life.

3.

Charge the battery cartridge with room tem-

perature at 10 °C - 40 °C (50 °F - 104 °F). Let

a hot battery cartridge cool down before

charging it.

4.

When not using the battery cartridge, remove

it from the tool or the charger.

5.

Charge the battery cartridge if you do not use

it for a long period (more than six months).

FUNCTIONAL

DESCRIPTION

WARNING:

Always be sure that the tool is

switched off and the battery cartridge is removed

before adjusting or checking function on the tool.

Installing or removing battery

cartridge

CAUTION:

Always switch off the tool before

installing or removing of the battery cartridge.

CAUTION:

Hold the tool and the battery car-

tridge firmly when installing or removing battery

cartridge.

Failure to hold the tool and the battery

cartridge firmly may cause them to slip off your hands

and result in damage to the tool and battery cartridge

and a personal injury.

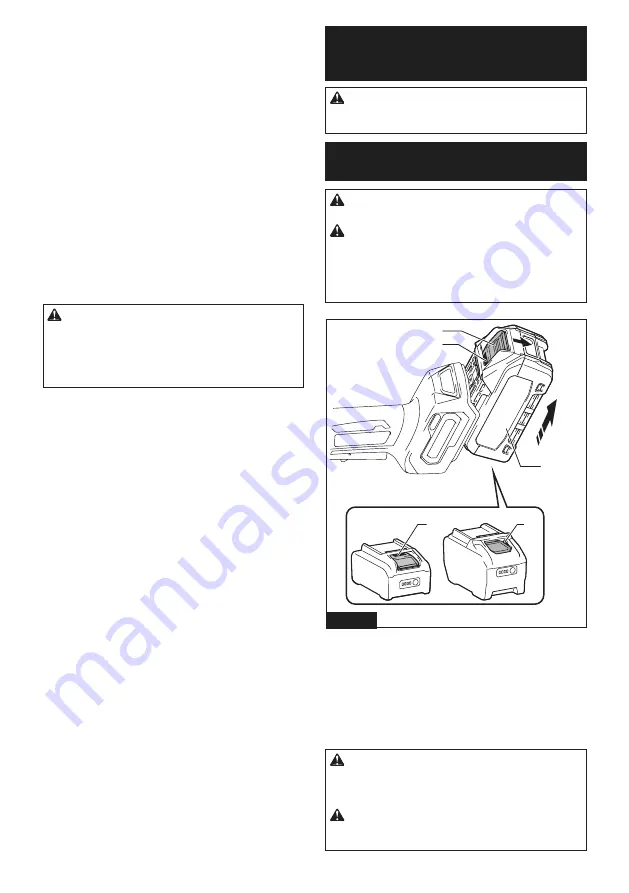

3

1

1

1

2

Fig.1

►

1.

Red indicator

2.

Button

3.

Battery cartridge

To remove the battery cartridge, slide it from the tool

while sliding the button on the front of the cartridge.

To install the battery cartridge, align the tongue on the

battery cartridge with the groove in the housing and slip

it into place. Insert it all the way until it locks in place

with a little click. If you can see the red indicator as

shown in the figure, it is not locked completely.

CAUTION:

Always install the battery cartridge

fully until the red indicator cannot be seen.

If not,

it may accidentally fall out of the tool, causing injury to

you or someone around you.

CAUTION:

Do not install the battery cartridge

forcibly.

If the cartridge does not slide in easily, it is

not being inserted correctly.