13 ENGLISH

20.

Do not use cloth work gloves during operation.

Fibers from cloth gloves may enter the tool, which

causes tool breakage.

21.

Before operation, make sure that there is no

buried object such as electric pipe, water pipe

or gas pipe in the workpiece.

Otherwise, it may

cause an electric shock, electrical leakage or gas

leak.

22.

If a blotter is attached to the wheel, do not

remove it. The diameter of the blotter must be

larger than the lock nut, outer flange, and inner

flange.

23.

Before installing a grinding wheel, always

check that the blotter part does not have any

abnormalities such as chips or cracks.

24.

Tighten the lock nut properly.

Overtightening

the wheel can cause breakage and insufficient

tightening can cause fluttering.

SAVE THESE INSTRUCTIONS.

WARNING:

DO NOT let comfort or familiarity

with product (gained from repeated use) replace

strict adherence to safety rules for the subject

product. MISUSE or failure to follow the safety

rules stated in this instruction manual may cause

serious personal injury.

FUNCTIONAL

DESCRIPTION

CAUTION:

Always be sure that the tool is

switched off and unplugged before adjusting or

checking function on the tool.

Tool protection system

The tool is equipped with a tool protection system. This

system automatically reduces or cuts off power to the

motor to extend tool life. The tool will automatically

reduce power or stop during operation if the tool is

placed under one of the following conditions:

Overload protection

When the tool is operated in a manner that causes it

to draw an abnormally high current, the tool reduces

power automatically without any indication. In this

situation, remove the cause of the overload so that the

rotation speed recovered.

Overheat protection

Country specific

When the tool is overheated, the tool stops automat-

ically and the indication lamp blinks in red. In this

situation, let the tool cool down. You can turn the tool

on again after the lamp changes the color from red to

green.

Indication lamp

►

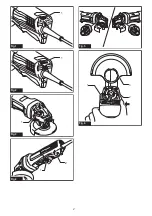

Fig.1:

1.

Indication lamp

The indication lamp lights up green when the tool is

plugged.

If the indication lamp blinks in red, the overheat pro-

tection, Active Feedback sensing Technology, or the

accidental re-start preventive function stops operation.

In this situation, switch off the tool. Then, turn the tool

on to restart.

If the indication lamp lights up in red after switch off the

tool, the tool is overheated. In this situation, cool down

the tool and wait until the indication lamp lights up in

green.

Speed adjusting dial

Only for model GA4593 / GA5093

CAUTION:

If the tool is operated continuously

at low speeds for a long time, the motor will get

overloaded and heated up.

CAUTION:

The speed adjusting dial can be

turned only as far as 5 and back to 1. Do not force

it past 5 or 1, or the speed adjusting function may

no longer work.

The rotating speed can be changed by turning the

speed adjusting dial to a given number setting from 1 to

5. Higher speed is obtained when the dial is turned in

the direction of number 5. And lower speed is obtained

when it is turned in the direction of number 1. Refer to

the below table for the relationship between the number

settings on the dial and the approximate rotating speed.

Number

Rated speed

1

2,800 min

-1

(/min)

2

4,500 min

-1

(/min)

3

6,500 min

-1

(/min)

4

8,000 min

-1

(/min)

5

11,500 min

-1

(/min)

►

Fig.2:

1.

Speed adjusting dial

Shaft lock

WARNING:

Never actuate the shaft lock when

the spindle is moving.

It may cause serious injury or

the tool damage.

Press the shaft lock to prevent spindle rotation when

installing or removing accessories.

►

Fig.3:

1.

Shaft lock

Summary of Contents for GA4594

Page 2: ...2 1 Fig 1 1 Fig 2 1 Fig 3 1 2 Fig 4 Fig 5 1 2 3 Fig 6 ...

Page 3: ...3 2 B 1 A B Fig 7 2 1 A C C Fig 8 Fig 9 1 2 4 3 Fig 10 1 2 Fig 11 1 2 3 4 Fig 12 ...

Page 5: ...5 1 Fig 21 1 Fig 22 1 Fig 23 1 2 4 5 6 3 Fig 24 Fig 25 1 2 Fig 26 15 Fig 27 Fig 28 ...

Page 6: ...6 Fig 29 Fig 30 Fig 31 Fig 32 1 2 2 2 Fig 33 ...

Page 145: ...145 ...

Page 146: ...146 ...

Page 147: ...147 ...