7 ENGLISH

FUNCTIONAL

DESCRIPTION

CAUTION:

Always be sure that the tool is

switched off and unplugged before adjusting or

checking function on the tool.

CAUTION:

Return the slide switch to the “O

(OFF)” position in case of accidental unplugging,

blackout, or the power is cut unintentionally.

Otherwise the tool may start suddenly when the

power returns and it may result in personal injury.

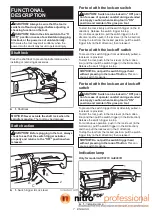

Shaft lock

Press the shaft lock to prevent spindle rotation when

installing or removing accessories.

1

►

1.

Shaft lock

NOTICE:

Never actuate the shaft lock when the

spindle is moving.

The tool may be damaged.

Switch action

CAUTION:

Before plugging in the tool, always

check to see that the switch trigger actuates

properly and returns to the "OFF" position when

released.

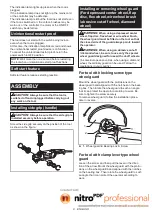

A

B

C

2

1

►

1.

Switch trigger

2.

Lock lever

For tool with the lock-on switch

CAUTION:

Switch can be locked in "ON" posi-

tion for ease of operator comfort during extended

use. Apply caution when locking tool in "ON"

position and maintain firm grasp on tool.

To start the tool, simply pull the switch trigger (in the B

direction). Release the switch trigger to stop.

For continuous operation, pull the switch trigger (in the B

direction) and then push in the lock lever (in the A direction).

To stop the tool from the locked position, pull the switch

trigger fully (in the B direction), then release it.

For tool with the lock-off switch

To prevent the switch trigger from accidentally pulled, a

lock lever is provided.

To start the tool, push in the lock lever (in the A direc

-

tion) and then pull the switch trigger (in the B direction).

Release the switch trigger to stop.

NOTICE:

Do not pull the switch trigger hard

without pressing in the lock-off button.

This can

cause switch breakage.

For tool with the lock-on and lock-off

switch

CAUTION:

Switch can be locked in "ON" posi-

tion for ease of operator comfort during extended

use. Apply caution when locking tool in "ON"

position and maintain firm grasp on tool.

To prevent the switch trigger from accidentally pulled, a

lock lever is provided.

To start the tool, push in the lock lever (in the A direc

-

tion) and then pull the switch trigger (in the B direction).

Release the switch trigger to stop.

For continuous operation, push in the lock lever (in the

A direction), pull the switch trigger (in the B direction)

and then pull the lock lever (in the C direction).

To stop the tool from the locked position, pull the switch

trigger fully (in the B direction), then release it.

NOTICE:

Do not pull the switch trigger hard

without pressing in the lock-off button.

This can

cause switch breakage.

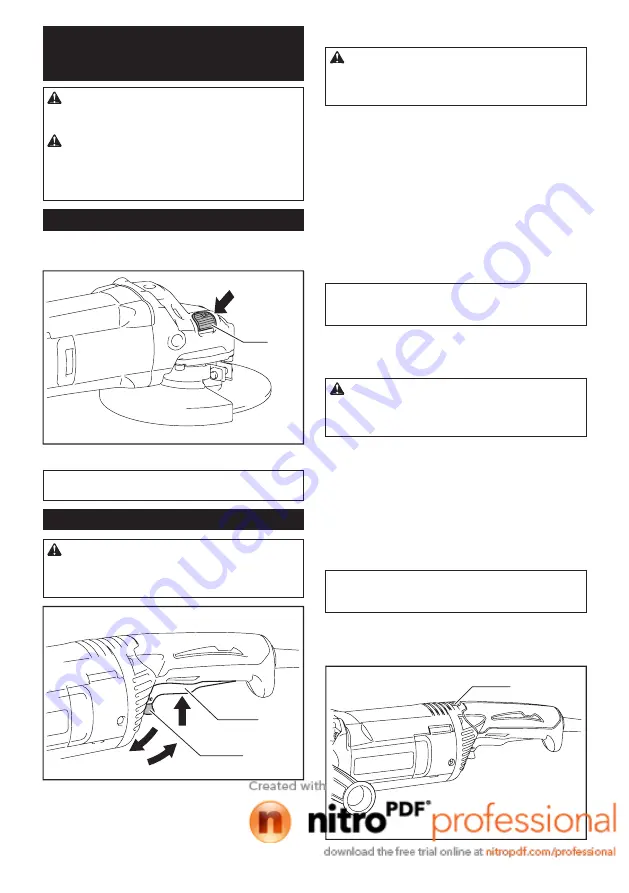

Indication lamp

Only for model GA7061R / GA9061R

1

►

1.

Indication lamp