13 ENGLISH

Unintentional restart proof

The tool does not start with the switch being lock-on

even when the tool is plugged.

At this time, the indication lamp blinks in red to show the

unintentional restart proof device is working.

To cancel the unintentional restart proof, return the

switch to OFF position.

NOTE:

Wait more than one second before restarting

the tool when unintentional restart proof works.

Active Feedback sensing Technology

CAUTION:

Hold the tool firmly until the rota

-

tion stops.

The tool electronically detects situations where the

wheel or accessory may be at risk to be bound. In such

situation, the tool automatically shuts off the power to

prevent further rotation of the spindle (this does not

prevent kickback).

At this time, the indication lamp blinks in red and shows

the Active Feedback sensing Technology is working.

To restart the tool, switch off the tool first, remove the

cause of sudden drop in the rotation speed, and then

turn the tool on.

Soft start feature

Soft start feature reduces starting reaction.

ASSEMBLY

CAUTION:

Always be sure that the tool is

switched off and unplugged before carrying out

any work on the tool.

Installing side grip (handle)

CAUTION:

Always be sure that the side grip is

installed securely before operation.

CAUTION:

You can install the side grip on the

3 holes. Install the side grip on one of the holes

according to the operation.

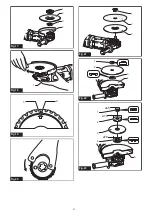

Screw the side grip securely on the position of the tool

as shown in the figure.

►

Fig.7

Installing or removing loop handle

Optional accessory

CAUTION:

Always be sure the bolts on the

loop handle is securely tightened before use.

CAUTION:

Hold the gripping area of the loop

handle specified in the figure. Also, keep the hand

away from the metal part of the grinder during

operation.

Touching the metal part may result in

electric shock, if the cutting attachment cuts live wire

unexpectedly.

The loop handle can be more comfortable than the orig

-

inal side grip for some applications. To install the loop

handle, mount it onto the tool as illustrated and tighten

two bolts to fix it.

To remove the loop handle, follow the installation proce-

dure in reverse.

►

Fig.8:

1.

Loop handle

2.

Bolt

3.

Gripping area

Installing or removing wheel guard

(For depressed center wheel, flap disc,

flex wheel, wire wheel brush / abrasive

cut-off wheel, diamond wheel)

WARNING:

When using a depressed center

wheel, flap disc, flex wheel or wire wheel brush,

the wheel guard must be fitted on the tool so that

the closed side of the guard always points toward

the operator.

WARNING:

When using an abrasive cut-off

/ diamond wheel, be sure to use only the special

wheel guard designed for use with cut-off wheels.

(In some European countries, when using a diamond

wheel, the ordinary guard can be used. Follow the

regulations in your country.)

For tool with locking screw type

wheel guard

Mount the wheel guard with the protrusions on the

wheel guard band aligned with the notches on the bear

-

ing box. Then rotate the wheel guard to such an angle

that it can protect the operator according to work. Be

sure to tighten the screw securely.

To remove wheel guard, follow the installation proce

-

dure in reverse.

►

Fig.9:

1.

Wheel guard

2.

Bearing box

3.

Screw

For tool with clamp lever type wheel guard

Optional accessory

WARNING:

The wheel guard must be fitted

on the tool so that the closed side of the guard

always points toward the operator.

Loosen the nut, and then pull the lever in the direction

of the arrow.

►

Fig.10:

1.

Nut

2.

Lever

Mount the wheel guard with the protrusions on the

wheel guard band aligned with the notches on the bear

-

ing box. Then rotate the wheel guard to such an angle

that it can protect the operator according to work.

►

Fig.11:

1.

Wheel guard

2.

Bearing box

►

Fig.12:

1.

Wheel guard

Securely tighten the nut using a spanner, and then

close the lever in direction of the arrow to fasten the

wheel guard. If the lever is too tight or too loose to

fasten the wheel guard, open the lever and then loosen

or tighten the nut using the spanner to adjust the tight

-

ening of the wheel guard band.

►

Fig.13:

1.

Nut

2.

Lever

To remove wheel guard, follow the installation proce

-

dure in reverse.

Summary of Contents for GA7071

Page 2: ...1 Fig 1 1 2 3 Fig 2 1 2 3 Fig 3 B C 2 1 A Fig 4 B C 2 1 A Fig 5 1 Fig 6 Fig 7 1 2 3 Fig 8 2 ...

Page 5: ...1 Fig 24 1 Fig 25 1 2 4 5 6 3 Fig 26 Fig 27 1 2 Fig 28 Fig 29 Fig 30 Fig 31 5 ...

Page 6: ...Fig 32 Fig 33 1 Fig 34 1 2 Fig 35 6 ...

Page 7: ...1 2 3 5 4 6 3 3 8 5 9 7 8 5 6 11 10 5 12 13 14 20 18 19 5 17 21 3 22 5 2 2 15 16 Fig 36 7 ...

Page 118: ...118 ...

Page 119: ...119 ...