R

epair

P 6 / 8

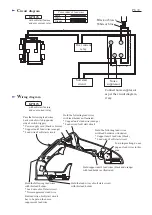

< 8 > Replacement of the electrical parts in handle

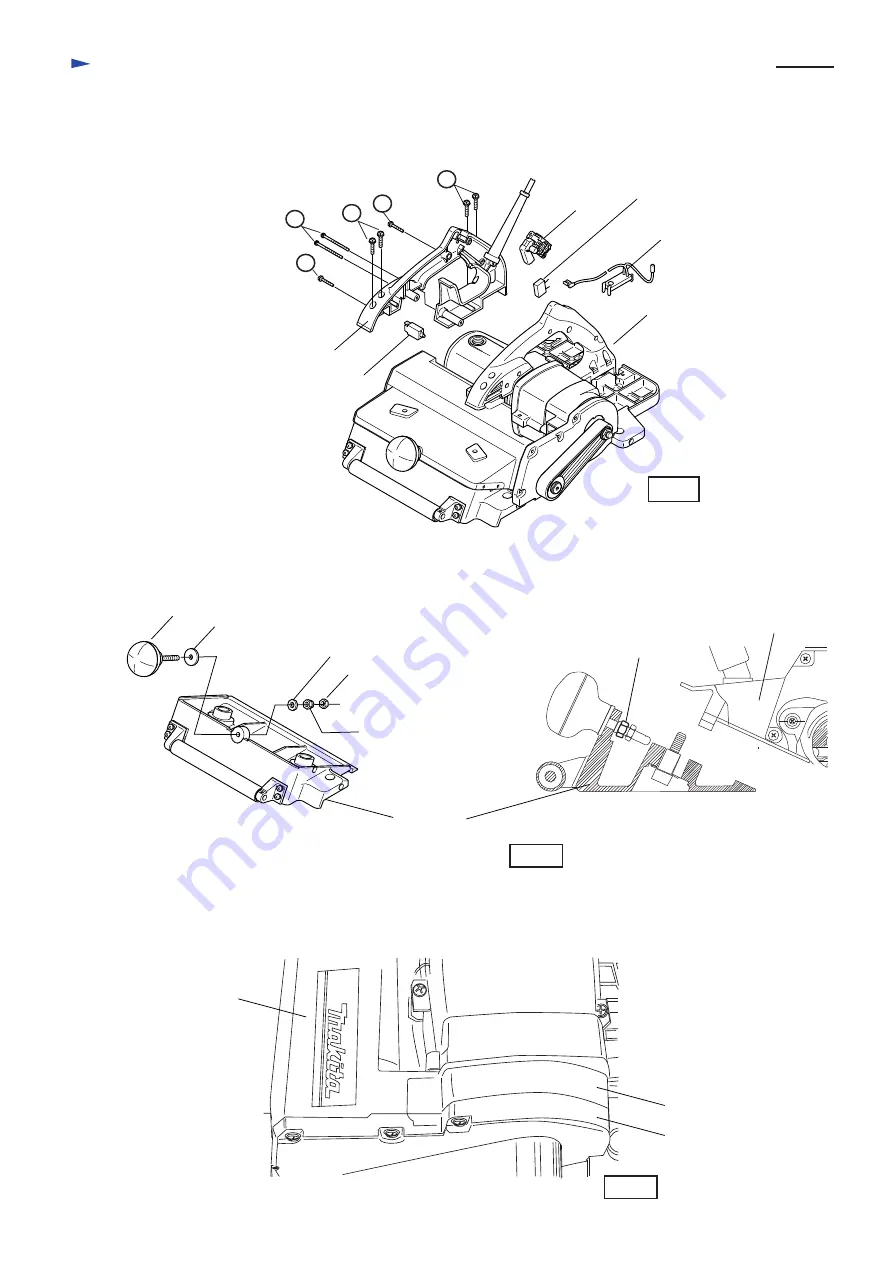

< 9 > Mounting and adjustment of knob

Before mounting knob to front base, adjust it with hex lock nut M8-13, so that the knob can be turned smoothly, but

without wobbling. See Fig. 14.

( 1 ) Remove the following screws.

1. Pan head screw M5x28 : 4 pcs.

2. Pan head screw M4x28 : 2 pcs.

3. Pan head screw M4x60 : 2 pcs.

See Fig. 13.

( 2 ) Removed handle R. The electrical parts can be replaced.

See Fig.13.

< 10 > Mounting bracket cove and main bracket

Main bracket has to be closely mounted to bracket cover. And both of them has to be mounted to main base firmly

and closely. See Fig. 15.

< 11 >

< 12 >

< 13 >

< 14 >

< 15 >

< 16 >

< 17 >

< 18 >

< 19 >

< 20 >

< 21 >

< 22 >

< 23 >

< 24 >

< 25 >

< 26 >

Fig. 13

Fig. 14

Fig. 15

Fig. 16

Fig. 17

Fig. 18

Fig. 19

Fig. 20

Fig. 21

Fig. 22

Fig. 23

Fig. 24

Fig. 25

Fig. 26

Handle R

Handle L

Switch

Soft start circuit

1

1

2

2

3

Over current relay

Noise suppressor

Knob

Flat washer 8 (large)

Flat washer 8 (small)

Hex nut M8

Hex lock nut M8-13

Hex lock

nut M8-13

Front base

Main base

Bracket cover

Main bracket

Main base