7 ENGLISH

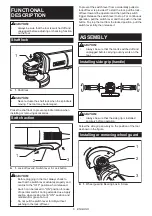

1

2

3

►

1.

Wheel guard

2.

Bearing box

3.

Screw

CAUTION:

•

When using a depressed center grinding wheel/

Multi-disc, flex wheel, wire wheel brush, cut-off

wheel or diamond wheel, the wheel guard must

be fitted on the tool so that the closed side of the

guard always points toward the operator.

Mount the wheel guard with the protrusion on the wheel

guard band aligned with the notch on the bearing box.

Then rotate the wheel guard around 180 degrees. Be

sure to tighten the screw securely.

To remove wheel guard, follow the installation proce-

dure in reverse.

Installing or removing depressed

center grinding wheel/Multi-disc

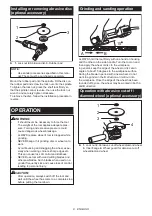

1

2

3

►

1.

Lock nut

2.

Depressed center wheel/Multi-disc

3.

Inner flange

WARNING:

•

Always use supplied guard when depressed

center grinding wheel/Multi-disc is on tool.

Wheel can shatter during use and guard helps

to reduce chances of personal injury.

Mount the inner flange onto the spindle. Fit the wheel/

disc on the inner flange and screw the lock nut onto the

spindle.

To tighten the lock nut, press the shaft lock firmly so

that the spindle cannot revolve, then use the lock nut

wrench and securely tighten clockwise.

1

2

►

1.

Lock nut wrench

2.

Shaft lock

To remove the wheel, follow the installation procedure

in reverse.

WARNING:

•

Only actuate the shaft lock when the spindle is

not moving.

Installing or removing flex wheel

(optional accessory)

1

2

3

4

►

1.

Lock nut

2.

Flex wheel

3.

Back up pad

4.

Inner

flange

WARNING:

•

Always use supplied guard when flex wheel is

on tool. Wheel can scatter during use and guard

helps to reduce chances of personal injury.

Follow instructions for depressed center grinding wheel/

Multi-disc but also use back up pad over wheel. See

order of assembly on accessories page in this manual.