9 ENGLISH

Cutting capacity

Maximum cutting capacity varies depending on the

cutting angle and workpiece shape.

Max. cutting capacity with a brand-new cut-off

wheel

Cutting angle /

Workpiece shape

90°

45°

127 mm

127 mm

102 x 194 mm

70 x 233 mm

115 x 103 mm

119 x 119 mm

106 x 106 mm

137 x 137 x 10 mm 100 x 100 x 10 mm

Securing workpiece

CAUTION:

Always place the thread holder on

the shaft threads when securing the workpiece.

Failure to do so may result in insufficient securing of

the workpiece. This could cause the workpiece to be

ejected or cause a dangerous breakage of the wheel.

While the thread holder is lifted, the vise plate can be

moved in and out quickly. To grip a workpiece, push the

handle until the vise plate contacts the workpiece then

return the thread holder. Turn the handle clockwise until

the workpiece is securely retained.

►

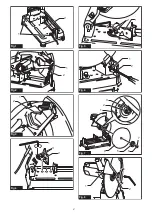

Fig.10:

1.

Handle

2.

Thread holder

3.

Vise plate

When the cut-off wheel has worn down considerably,

place a spacer block behind the workpiece as shown

in the figure. You can more efficiently utilize the worn

wheel by using the mid point on the periphery of the

wheel to cut the workpiece. Use a sturdy and non-flam

-

mable material for a spacer block.

►

Fig.11:

1.

Spacer block

When cutting workpieces over 85 mm wide at an angle,

attach a straight piece of wood (spacer) over 190 mm

long x 45 mm wide to the guide plate as shown in the

figure. Attach this spacer with screws through the holes

in the guide plate. Make sure that the cut-off wheel does

not contact the spacer when the tool head is depressed.

►

Fig.12:

1.

Guide plate

2.

Spacer block (over 190

mm long x45 mm wide)

3.

Workpiece (over

85 mm wide)

4.

Vise plate

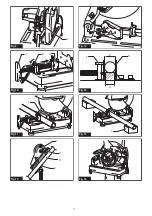

►

Fig.13

When the cut-off wheel has worn down, raise the cutting

position by putting a spacer block which is slightly nar

-

rower than the workpiece as shown in the figure. This

will help you to utilize the wheel economically.

►

Fig.14:

1.

Vise plate

2.

Workpiece diameter

3.

Guide plate

4.

Spacer block width

Long workpieces must be supported by blocks on

either side so that it will be level with the base top. Use

non-flammable material for supporting blocks.

►

Fig.15:

1.

Supporting block

Carrying tool

Fold down the tool head and lock it. Hold the handle

when carrying.

►

Fig.16

MAINTENANCE

CAUTION:

Always be sure that the tool is

switched off and unplugged before attempting to

perform inspection or maintenance.

NOTICE:

Never use gasoline, benzine, thinner,

alcohol or the like. Discoloration, deformation or

cracks may result.

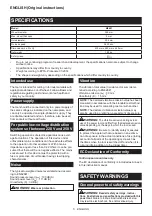

Replacing carbon brushes

►

Fig.17:

1.

Limit mark

Check the carbon brushes regularly.

Replace them when they wear down to the limit mark.

Keep the carbon brushes clean and free to slip in the

holders. Both carbon brushes should be replaced at the

same time. Use only identical carbon brushes.

1.

Use a screwdriver to remove the brush holder

caps.

2.

Take out the worn carbon brushes, insert the new

ones and secure the brush holder caps.

►

Fig.18:

1.

Brush holder cap

To maintain product SAFETY and RELIABILITY,

repairs, any other maintenance or adjustment should

be performed by Makita Authorized or Factory Service

Centers, always using Makita replacement parts.