P 4 / 6

R

epair

[3] -2. Large spiral bevel gear and Ball bearing 6203ZZ

DISASSEMBLING

Fig. 7

Fig. 8

1) Separate Bearing box from Gear housing complete by unscrewing four M6x22 Hex socket head bolts.

It is not necessary to remove Carbon brushes.

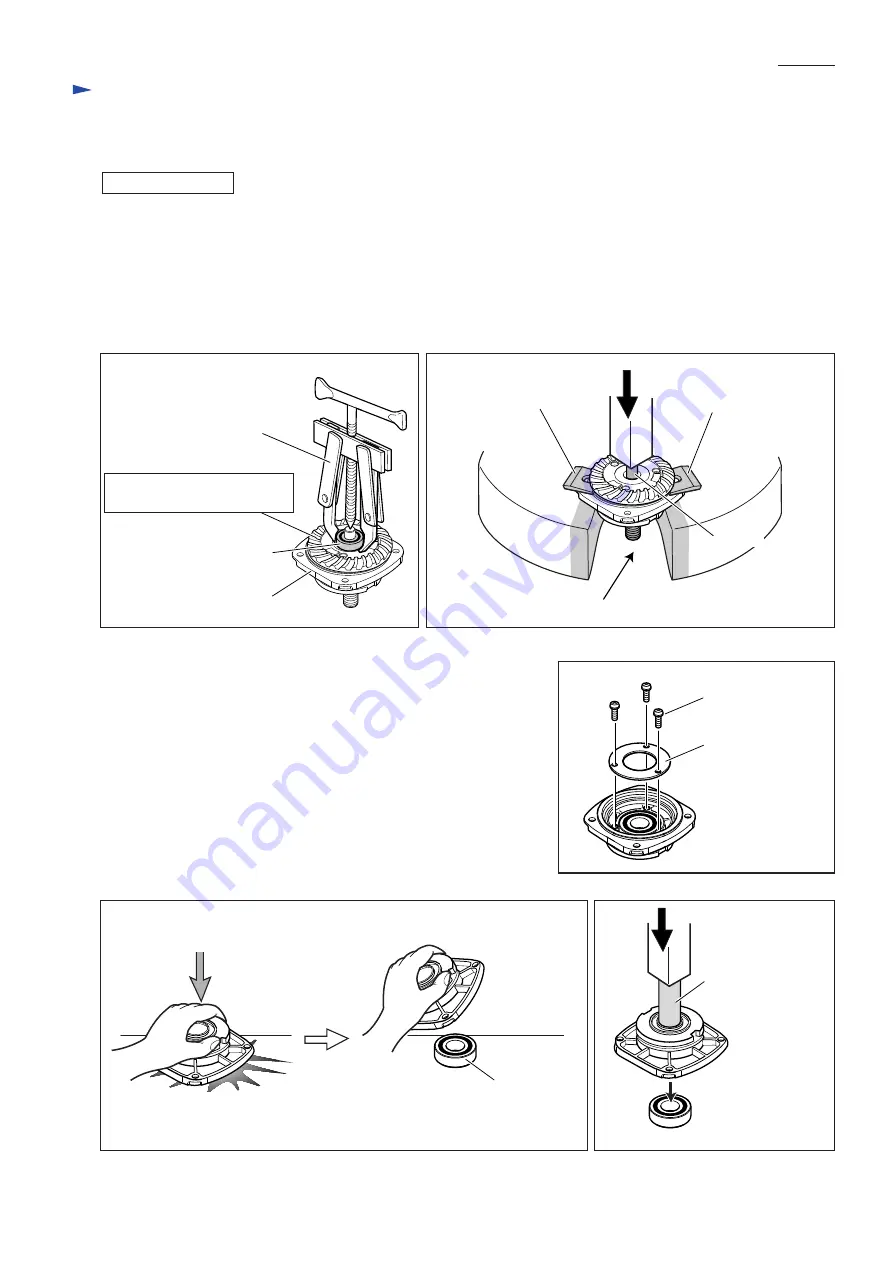

2) Remove Ball bearing 6000ZZ with Bearing Extractor (No.1R269). (Fig. 7)

3) Insert two Drill chuck removers (No.1R048, 1R049) between Large spiral bevel gear and Bearing box,

and set the Bearing box on the turn base of arbor press so that the wheel cover installation surface of

Bearing box is placed on the edge of the U-shaped notch of the turn base.

Then remove spindle by pressing down with arbor. (Fig. 8)

4) After removing Large spiral bevel gear, separate Bearing retainer 50

by removing three M5x16 Pan head screws. (Fig. 9)

5) Remove Ball bearing 6203ZZ by hitting Bearing box straight down

against flat surface of work-bench. (Fig. 10)

If cannot be removed, use arbor press and a round bar for arbor of

an appropriate size as illustrated in Fig. 11.

Note: The gear and the ball bearing can be replaced without disassembling the Motor section.

Fig. 10

Fig. 11

Ball bearing

6203ZZ

Round bar for arbor

No.1R269

U-shaped notch of arbor press

Ball bearing 6000ZZ

Bearing box

Drill Chuck Remover 11

(No.1R048)

Drill Chuck Remover 15

(No.1R049)

Spindle

Fig. 9

Pan head screw

M5x16 (3 pcs)

Bearing retainer 50

MT900: Spiral bevel gear 53B

MT901: Spiral bevel gear 53A