5

5.

Do not attach a saw chain woodcarving blade

or toothed saw blade.

Such blades create

frequent kickback and loss of control.

6.

Do not "jam" the wheel or apply excessive

pressure. Do not attempt to make an

excessive depth of cut.

Overstressing the wheel

increases the loading and susceptibility to twisting

or binding of the wheel in the cut and the possibility

of kickback or wheel breakage.

7.

When wheel is binding or when interrupting a

cut for any reason, switch off the power tool

and hold the power tool motionless until the

wheel comes to a complete stop. Never

attempt to remove the wheel from the cut

while the wheel is in motion otherwise

kickback may occur.

Investigate and take

corrective action to eliminate the cause of wheel

binding.

8.

Do not restart the cutting operation in the

workpiece. Let the wheel reach full speed and

carefully reenter the cut.

The wheel may bind,

walk up or kickback if the power tool is restarted in

the workpiece.

9.

Support panels or any oversized workpiece to

minimize the risk of wheel pinching and

kickback.

Large workpieces tend to sag under

their own weight. Supports must be placed under

the workpiece near the line of cut and near the

edge of the workpiece on both sides of the wheel.

10.

Use extra caution when making a "pocket cut"

into existing walls or other blind areas.

The

protruding wheel may cut gas or water pipes,

electrical wiring or objects that can cause

kickback.

SAVE THESE INSTRUCTIONS.

WARNING:

DO NOT let comfort or familiarity with product

(gained from repeated use) replace strict adherence

to safety rules for the subject product. MISUSE or

failure to follow the safety rules stated in this

instruction manual may cause serious personal

injury.

OPERATING INSTRUCTIONS

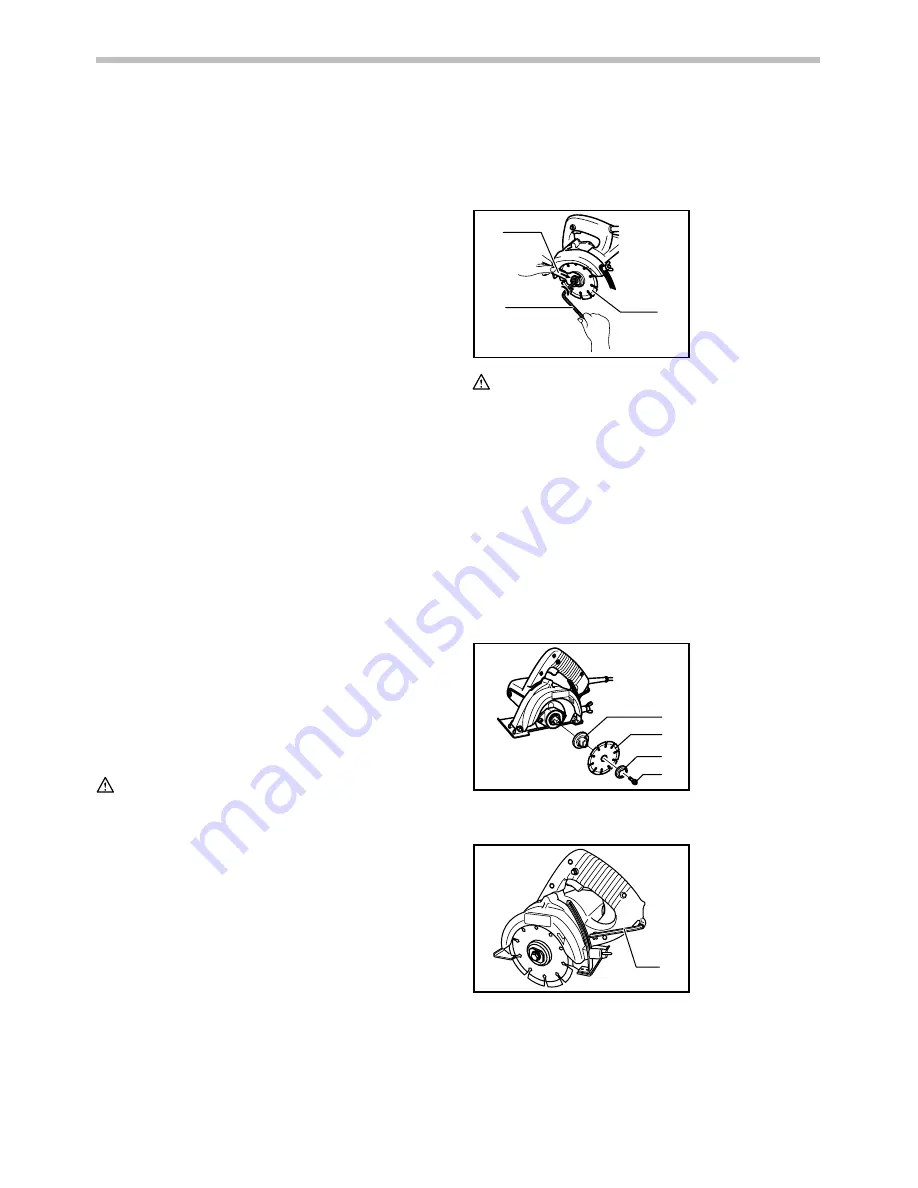

Removing or installing diamond wheel

(optional accessory)

1

2

3

001676

CAUTION:

•

Always be sure that the tool is switched off and

unplugged before installing or removing the wheel.

•

Use only the Makita wrench to install or remove the

wheel.

To remove the wheel, hold the outer flange with the

wrench and loosen the hex bolt clockwise with the hex

wrench. Then remove the hex bolt, outer flange and

wheel.

To install the wheel, follow the removal procedure in

reverse. Always install the wheel so that the arrow on the

wheel points in the same direction as the arrow on the

blade case. BE SURE TO TIGHTEN THE HEX BOLT

COUNTERCLOCKWISE SECURELY.

1

2

3

4

001677

Hex wrench storage

1

001678

When not in use, store the hex wrench as shown in the

figure to keep it from being lost.

1. Hex wrench

1. Inner flange

2. Diamond wheel

3. Outer flange

4. Hex bolt

1. Wrench

2. Hex wrench

3. Diamond wheel