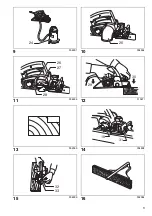

8

For the correct planer blade setting

Your planing surface will end up rough and uneven, unless the blade is set properly and securely. The blade must be

mounted so that the cutting edge is absolutely level, that is, parallel to the surface of the rear base.

Refer to some examples below for proper and improper settings.

Connecting a vacuum cleaner (Fig. 9)

For tool without nozzle

When you wish to perform clean planing operation, con-

nect a Makita vacuum cleaner to your tool. Before con-

necting the vacuum cleaner, remove the chip cover from

the tool. Then connect a hose of the vacuum cleaner to

the nozzle (optional accessory) as shown in the figures.

For tool with nozzle

When you wish to perform clean planing operation, con-

nect a Makita vacuum cleaner to your tool. Then connect

a hose of the vacuum cleaner to the nozzle as shown in

the figures.

Nozzle assembly (optional accessory)

Use of the special nozzle assembly will minimize chip

scatter, making for a cleaner work area.

(Fig. 10)

The nozzle assembly may be attached after the chip

cover on the machine body is removed. When slipping on

the assembly, fit the pin on it into the rear cover hole. Use

the chip cover screws to fasten it in place.

(Fig. 11)

Nozzle cleaning

Clean the nozzle regularly.

Use a compressed air to clean the clogged nozzle.

OPERATION

WARNING:

• To reduce the risk of injury to persons, do not oper-

ate without nozzle or chip cover in place.

Planing operation (Fig. 12)

First, rest the tool front base flat upon the workpiece sur-

face without the blades making any contact. Switch on

and wait until the blades attain full speed. Then move the

tool gently forward. Apply pressure on the front of tool at

the start of planing, and at the back at the end of planing.

Planing will be easier if you incline the workpiece in sta-

tionary fashion, so that you can plane somewhat downhill.

The speed and depth of cut determine the kind of finish.

The power planer keeps cutting at a speed that will not

result in jamming by chips. For rough cutting, the depth of

cut can be increased, while for a good finish you should

reduce the depth of cut and advance the tool more

slowly.

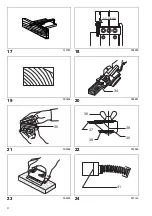

Shiplapping (Rabbeting) (Fig. 13, 14, 15, 16 & 17)

To make a stepped cut as shown in

Fig. 13

, use the edge

fence (guide rule).

Draw a cutting line on the workpiece. Insert the edge

fence into the hole in the front of the tool. Align the blade

edge with the cutting line.

(Fig. 14)

Adjust the edge fence until it comes in contact with the

side of the workpiece, then secure it by tightening the

screw.

(Fig. 15)

When planing, move the tool with the edge fence flush

with the side of the workpiece. Otherwise uneven planing

may result.

Max. shiplapping (Rabbeting) depth is 23 mm.

You may wish to add to the length of the fence by attach-

ing an extra piece of wood. Convenient holes are pro-

vided in the fence for this purpose, and also for attaching

an extension guide (optional accessory).

(Fig. 16

& 17

)

(A)

(B)

(B)

(A)

(B)

(A)

(A) Front base (Movable shoe)

(B) Rear base (Stationary shoe)

Correct setting

Nicks in surface

Gouging at start

Gouging at end

Although this side view cannot show it,

the edges of the blades run perfectly

parallel to the rear base surface.

Cause: One or both blades fails to

have edge parallel to rear

base line.

Cause: One or both blade edges fails

to protrude enough in relation

to rear base line.

Cause: One or both blade edges

protrudes too far in relation to

rear base line.

Summary of Contents for N1923B

Page 5: ...5 25 26 44 43 42 43 004903 004905 ...

Page 61: ...61 ...

Page 62: ...62 ...

Page 63: ...63 ...