8

lumber. This will show exactly how the cut will look as

well as enable you to check dimensions.

• When using the straight guide, be sure to install it on

the right side in the feed direction. This will help to keep

it flush with the side of the workpiece.

(Fig. 7)

Straight guide (Fig. 8)

The straight guide is effectively used for straight cuts

when chamfering or grooving.

To install the straight guide, insert the guide bars into the

holes in the tool base. Adjust the distance between the bit

and the straight guide. At the desired distance, tighten the

wing bolts to secure the straight guide in place.

(Fig. 9)

When cutting, move the tool with the straight guide flush

with the side of the workpiece.

If the distance (A) between the side of the workpiece and

the cutting position is too wide for the straight guide, or if

the side of the workpiece is not straight, the straight guide

cannot be used. In this case, firmly clamp a straight board

to the workpiece and use it as a guide against the router

base. Feed the tool in the direction of the arrow.

(Fig. 10)

Templet guide (Accessory) (Fig. 11)

The templet guide provides a sleeve through which the bit

passes, allowing use of the tool with templet patterns.

To install the templet guide, loosen the screws on the tool

base, insert the templet guide and then tighten the

screws.

(Fig. 12)

Secure the templet to the workpiece. Place the tool on the

templet and move the tool with the templet guide sliding

along the side of the templet.

(Fig. 13)

NOTE:

• The workpiece will be cut a slightly different size from

the templet. Allow for the distance (X) between the bit

and the outside of the templet guide. The distance (X)

can be calculated by using the following equation:

Distance (X) = (outside diameter of the templet guide -

bit diameter) / 2

Dust nozzle set (Accessory) (Fig. 14 & 15)

Use the dust nozzle for dust extraction. Install the dust

nozzle on the tool base using the thumb screw so that

protrusion on the dust nozzle fit to the notch in the tool

base.

Then connect a vacuum cleaner to the dust nozzle.

(Fig. 16)

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and

unplugged before attempting to perform inspection or

maintenance.

• Never use gasoline, benzine, thinner, alcohol or the

like. Discoloration, deformation or cracks may result.

To maintain product SAFETY and RELIABILITY, repairs,

any other maintenance or adjustment should be

performed by Makita Authorized Service Centers, always

using Makita replacement parts.

OPTIONAL ACCESSORIES

CAUTION:

• These accessories or attachments are recommended

for use with your Makita tool specified in this manual.

The use of any other accessories or attachments might

present a risk of injury to persons. Only use accessory

or attachment for its stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita Service Center.

• Straight & groove forming bits

• Edge forming bits

• Laminate trimming bits

• Straight guide

• Templet guide 25

• Templet guides

• Templet guide adapter

• Lock nut

• Collet cone 3/8”, 1/4”

• Collet cone 6 mm, 8 mm

• Wrench 13

• Wrench 22

• Dust nozzle set

Router bits

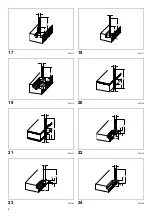

Straight bit (Fig. 17)

mm

009802

“U” Grooving bit (Fig. 18)

mm

009803

“V” Grooving bit (Fig. 19)

mm

009804

Drill point flush trimming bit (Fig. 20)

mm

009806

D A L

1

L

2

6

20 50 15

1/4”

8

8

60

25

6

8

50

18

1/4”

6

6

50

18

1/4”

D A L

1

L

2 R

6 6 50 18 3

D A L

1

L

2

1/4”

20 50 15 90°

D

A

L 1

L 2

L 3

8 8 60 20 35

6 6 60 18 28