R

epair

P 5 / 8

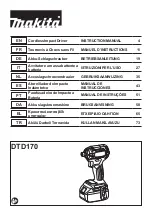

Fig.11

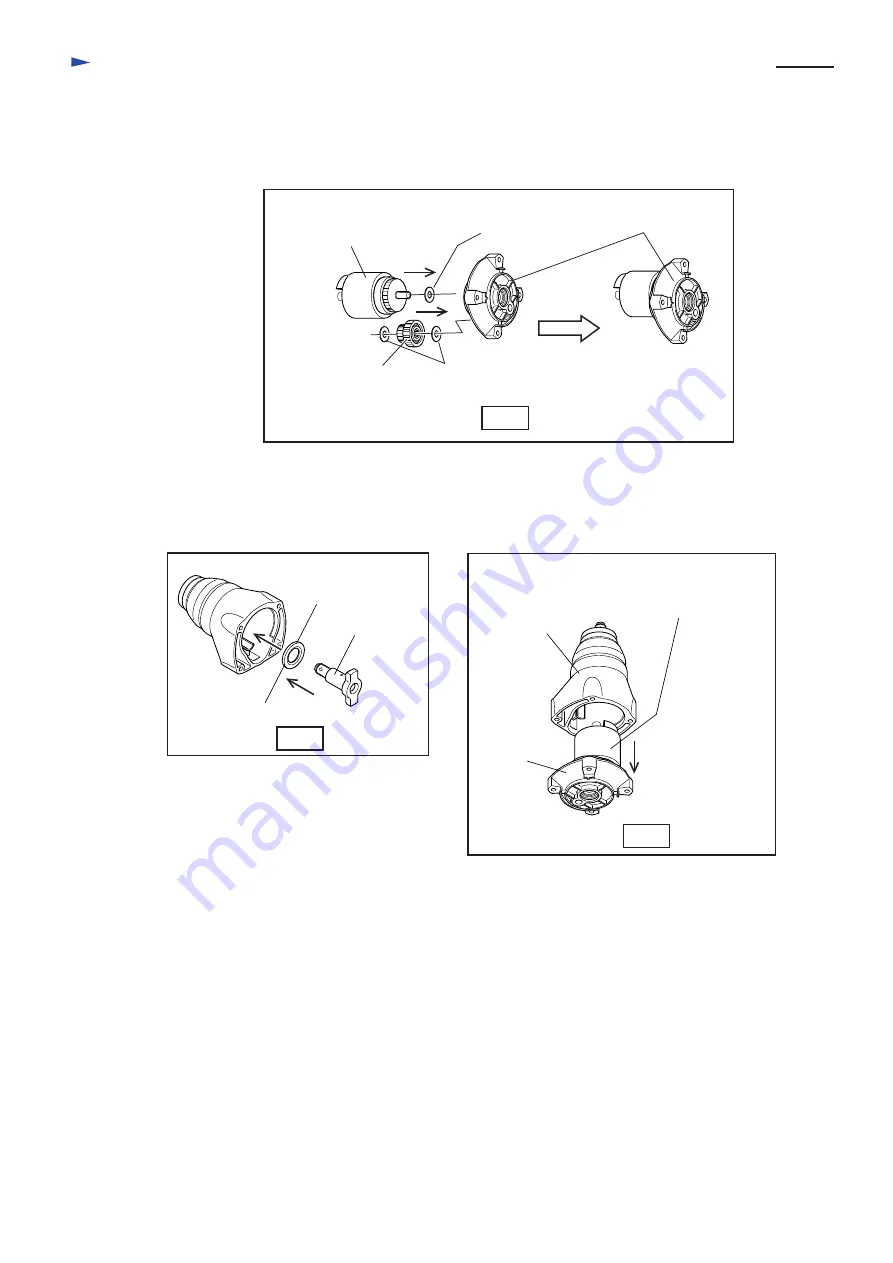

Fig.12

Fig.13

The hammer unit

(hammer, spindle,

compression spring 28, etc.)

Spur gear 19-41

Flat washer 8

Flat washer 8

( 4 ) Mount the hammer unit and spur gear 19-41 to the hammer case cover. See Fig. 11.

( 5 ) Mount flat washer 19 and anvil to the hammer case. See Fig. 12.

( 6 ) Mount hammer case cover as illustrated in Fig. 13. The assembling of mechanical section has been finished

at this step.

< Note >

Do not forget to mount flat washers 8 to the following portion.

* Spindle of hammer unit

* Shaft of hammer case cover for spur gear 19-41 (both side of spur gear 19-41)

This part can remain

in the hammer case.

Anvil

Flat washer 19

Hammer case

Hammer case

cover

Hammer unit

(hammer, spindle,

compression spring 28, etc.)

Hammer

case cover