Model No.

Description

PRODUCT

C

ONCEPT AND MAIN APPLICATIONS

S

pecification

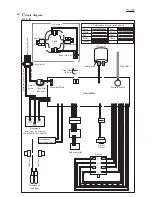

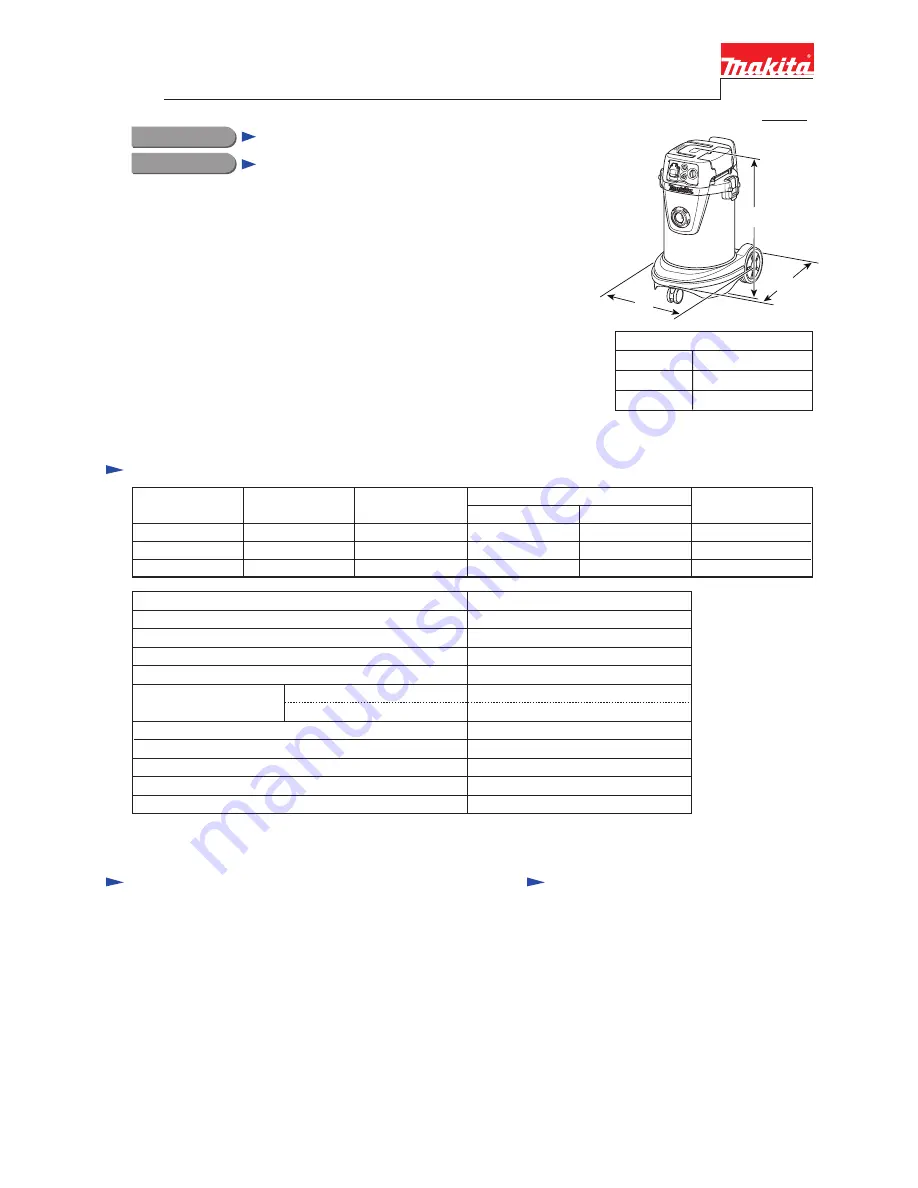

Dimensions: mm (")

Width (W)

Height (H)

Length (L)

552 (21-3/4)

398 (15-5/8)

685 (27)

VC3211M

Vacuum Cleaner

Model VC3211M is a Wet & Dry vacuum cleaner developed

based on Model VC3210L.

This product is approved for Dust Class M in accordance with

the EU standard.

Its main benefits are:

•

New automatic self-cleaning filtration system of our unique design

•

Power tool activation

*

•

32 Liter stainless steel tank

*

•

High maneuverability and easy mobility

*

*

The same advantage as Model VC3210L

P 1/

18

Continuous Rating (W)

Voltage (V)

Cycle (Hz)

Input

Output

Max. Output (W)

110

230

240

10.0

4.8

4.6

50/60

50/60

50/60

1,050

1,050

1,050

---

---

--

---

---

---

Current (A)

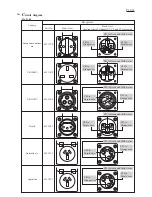

S

tandard equipment

Note:

The standard equipment for the tool shown above may vary by country.

O

ptional accessories

For

All models:

Hose complete 28-3.5 set .......... 1

(incl. Front cuff 38)

Front cuff 22 .............................. 1

Front cuff 24 .............................. 1

Belt hook

................................... 1

Hose band .................................. 1

Cap

............................................ 1

Poly bag 800x650 ...................... 1

Poly bag set

............................... 1

(incl. 10 pcs of Poly bag 800x650)

2.0

*

1

/ 3.5

*

2

22.0

Max. sealed suction: kPa

Max. air flow: m³/minute

Yes

Power tool activation

M

Dust class in accordance with the EU standard

Wet & Dry

Wet/Dry type

Yes

Variable suction power control by dial

Tank capacity: L

32

27

Weight according to EPTA-Procedure 01/2003

*

3

: kg (lbs)

*1

: with Hose complete 28-3.5

*2

: with Hose complete 38-2.5

*3

: with Poly bag 800x650

5.0 (16.4)

Power supply cord: m (ft)

Grounding

73

Noise: dB

16.9 (37.3)

Protection from electric shock

Dust

Water

Hose complete 28-2.5/ 28-3.5/

28-5.0/ 38-2.5/ 38-5.0

Front cuff 22/ 24/ 38

Filter bag set (5pcs/set)

Poly bag set (10 pcs/set)

Powder filter, Damper, Prefilter

Straight pipe, Bending pipe, Nozzle assembly,

Corner nozzle, Anchor nozzle, Round brush,

Cap, Cleaning set, Nozzle for wet application,

Belt hook, Hose band

W

H

This model is also available with cleaning set as VC3211MX1.

(See "Standard equipment" for what the cleaning set includes.)

For

VC3211MX1 only:

Cleaning set..................... 1

Includes one each of:

-Hose complete 38-2.5

-Straight pipe

-Bending pipe

-Nozzle assembly

-Corner nozzle

T

ECHNICAL INFORMATION

L