P 8/ 19

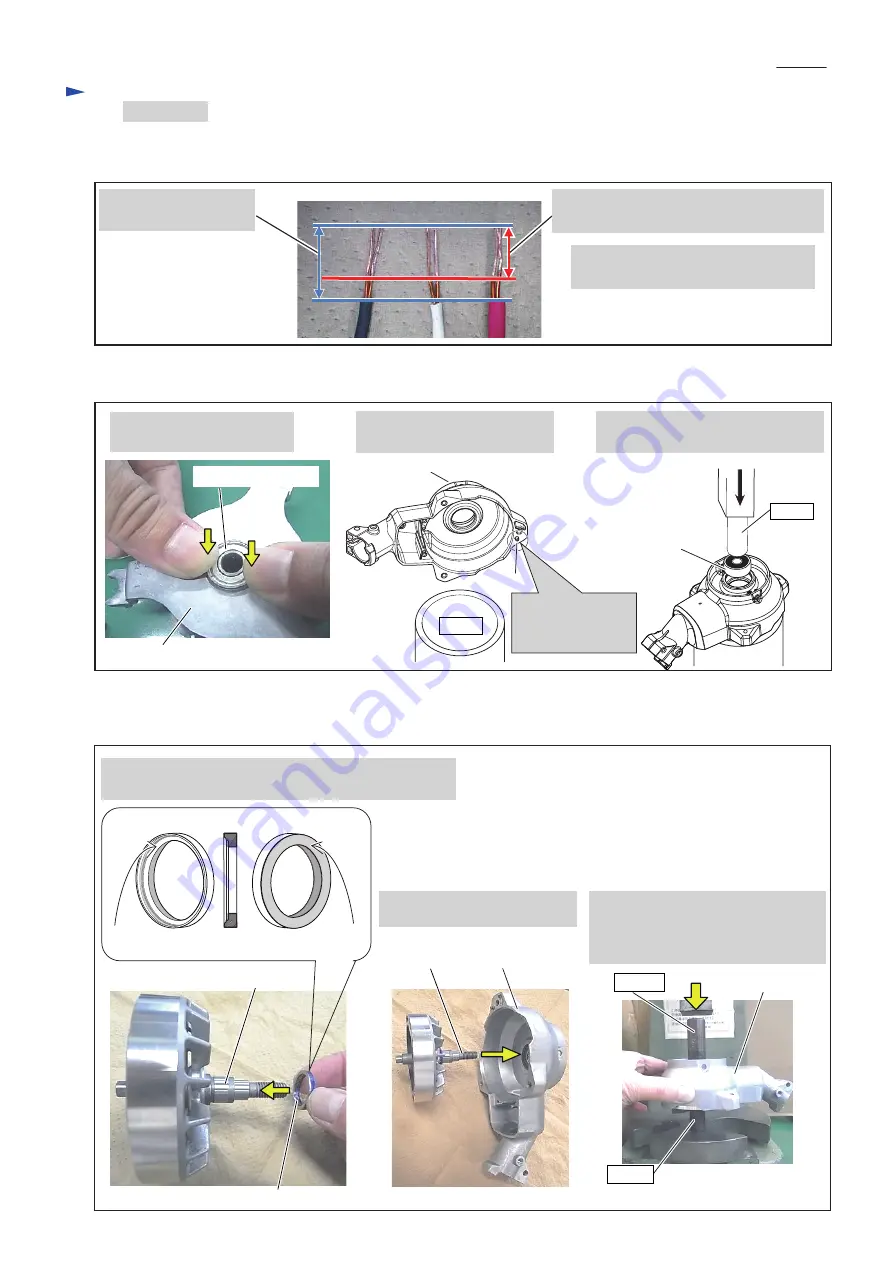

Fig. 2-2-2

Fig. 2-2-3

1. Mount Ball bearing 607ZZ

to Stator ass’y by hand.

2.

Set Motor housing on 1R023

while avoiding its pin.

(1) If Stator lead wires are cut as shown in

Fig. 2-1-5

, strip the ends. (

Fig. 2-2-1

)

(2) Mount Ball bearings to Stator ass’y and Motor housing. (

Fig. 2-2-2

)

(3) Mount Retaining ring R-28 to secure Ball bearing 6001DDW with 1R291.

Refer to

Fig. 2-1-9

in page 7.

Assemble Rotor to Motor housing. (

Fig. 2-2-3

)

3. Assemble Ball bearing 6001DDW

by pressing down 1R031.

Pin

Ball bearing 6001DDW

Stator ass’y

1R023

1R031

Motor housing

Fig. 2-2-1

1. Remove sheathes

by

13mm

from the tip.

2. Remove enamel with abrasive paper #100

by

11mm

from the tip.

Note

: It is necessary to remove enamel

to conduct electricity.

1. Place Ring 14 on the shaft of Rotor.

Note

: No paint portion of Ring 14 must be faced to Rotor.

1R027

1R028

2. Insert the shaft of Rotor into

the bearing in Motor housing.

3. Support Motor housing with 1R027.

Press down 1R028 while applying

1R028 on the bearing to assemble

Rotor into Motor housing.

Rotor

Shaft of Rotor

No paint portion

painted

in green

[cross section]

no paint

Motor housing

Ball bearing 607ZZ

Motor housing

Note

: Be sure to

avoid the pin

from 1R023.

2 ROTOR, STATOR ASS’Y

2-2 Assembling

Ring 14

Summary of Contents for XRU09

Page 1: ...REPAIR MANUAL XRU09...