MANUAL ACTIVATION OF THE SUBPRESSURE PUMP OR THE AGITATOR

When this function is activated, the user can manually turn on the subpressure pump or the agitator.

Manual activation is only possible when no washing program is running. When a washing program is

running the manual control button is inactive. Which lead can be manually operated (subpressure pump

PP

or the agitator

PPR

) is decided by factory or installer settings.

SERVICING BY THE INSTALLER

The controller is factory set for standard working conditions and it is designed for washing

the milk cooler – 2 programs, and to control the washing of the milking room – 2 programs.

Nonetheless, in order to provide optimized work of the controller in specific conditions, the

settings can be corrected to choose an appropriate program. The factory set washing programs can be

modified according to needs or a personalized program can be set.

When the controller is installed, the correctness of work of the entire washing system can be

checked in a fast mode.

SETTINGS CHART

Function

Symbol

Settings

Factory

settings

1

Entering the settings mode

U000

Access Code

121

2

Programs edition

EdPr

Editing the factory presets

and creating personalized

programs. Described

elsewhere within this

manual.

8 programs

See

Programs

Chart

3

Setting the program number

dPro

Pro1

Pro2

Pro3

Pro 4

Pro5

Pro6

Pro7

Pro8

Pro1

4

Setting the manual activation of the

subpressure pump or the agitator

UPP

0

– no function

1

– subpressure pump

2

– agitator

0

5

Setting the test program

UEL

0

– no function

1

– test function activated

0

8

Setting the maximum time without

Power supply after which the power is

restarted.

UAP

0

– no function (unlimited

time)

1

– 9 h

9

9

Returning to factory settings when the

controller is next activated.

PdOd

0

– no function

1

– back to factory settings

0

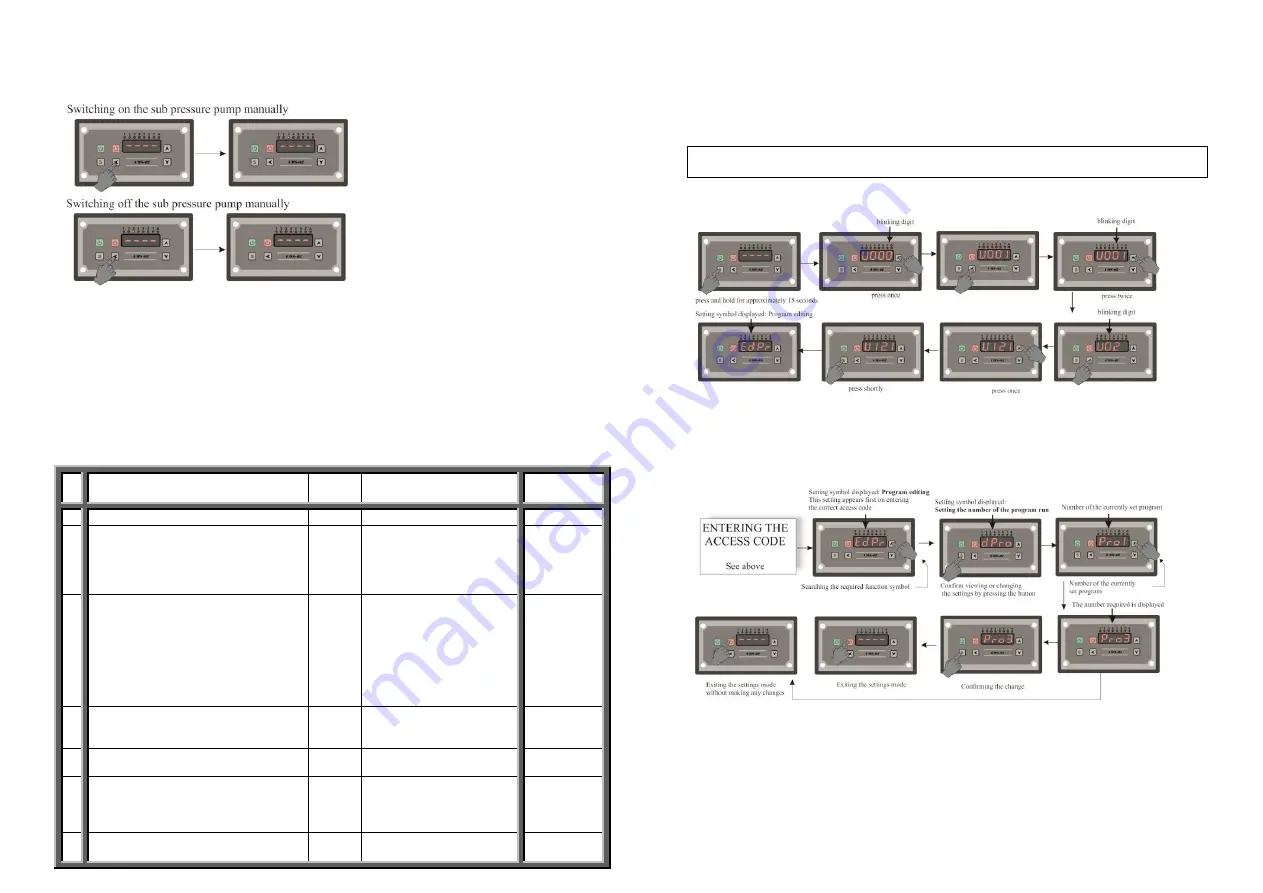

ENTERING THE SETTINGS AND PROGRAMMING MODE

The controller is secured against accidentally entering the service settings mode that is available to

service and maintenance personnel only.

This includes:

- having to press and hold the settings and programming mode button [8] for approximately 15 sec.

- having to enter the access code, which is given in the Settings Table.

- entering the access code is effected in several steps.

ATTENTION.

You are requested not to make the access code available to end users.

Below is the graphic representation of the procedure for entering the accdess code which enables to

enter the settings and programming mode.

SELECTING THE FUNCTION TO BE EDITED

In the Settings Table are all the functions available with the description and the list of possible values to

be set. If it is necessary to change any parameter within the settings, enter the settings mode (see above).

Next select a particular function to be modified. Below is graphic representation of a change to the

factory settings for the washing program No 1.

EDITING THE PROGRAMS – EdPr Function

The controller is equipped with:

- 4 pre-programmed washing programs which can be edited according to needs by the

installer.

- 4 washing programs to be programmed by the installer and not pre-programmed.

Each program can consist of the maximum of 50 steps.

The following parameters are ascribed to each step:

- status of 6 relays;

- status of the hydrostat input;

- duration of the step;

Summary of Contents for UMS-02

Page 6: ...Mounting slot...