6

FUNCTIONAL DESCRIPTION

CAUTION:

•

Always be sure that the tool is switched off and

unplugged before adjusting or checking function

on the tool.

Switch action

1

013096

CAUTION:

•

Before plugging in the tool, always be sure that the

tool is switched off.

To start the tool, move the switch lever to the "I" position.

To stop the tool, move the switch lever to the "O"

position.

ASSEMBLY

CAUTION:

•

Always be sure that the tool is switched off and

unplugged before carrying out any work on the

tool.

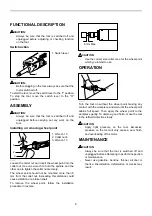

Installing or removing wheel point

1

2

3

013097

Loosen the collet nut and insert the wheel point into the

collet nut. Use one wrench to hold the spindle and the

other one to tighten the collet nut securely.

The wheel point should not be mounted more than 8

mm from the collet nut. Exceeding this distance could

cause vibration or a broken shaft.

To remove the wheel point, follow the installation

procedure in reverse.

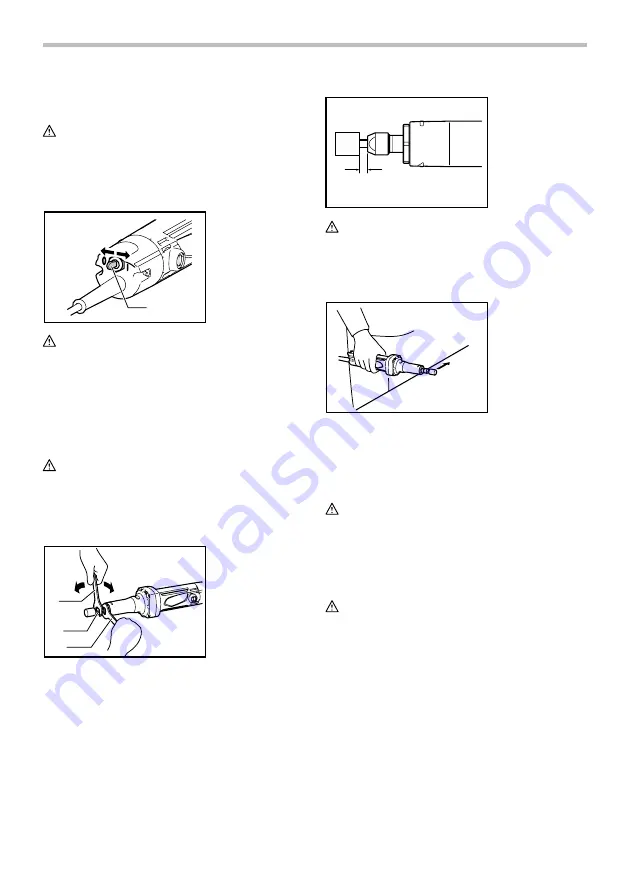

8mm Max.

013098

CAUTION:

•

Use the correct size collet cone for the wheel point

which you intend to use.

OPERATION

013099

Turn the tool on without the wheel point making any

contact with the workpiece and wait until the wheel point

attains full speed. Then apply the wheel point to the

workpiece gently. To obtain a good finish, move the tool

in the leftward direction slowly.

CAUTION:

•

Apply light pressure on the tool. Excessive

pressure on the tool will only cause a poor finish

and overloading of the motor.

MAINTENANCE

CAUTION:

•

Always be sure that the tool is switched off and

unplugged before attempting to perform inspection

or maintenance.

•

Never use gasoline, benzine, thinner, alcohol or

the like. Discoloration, deformation or cracks may

result.

1. Wrench 13

2. Collet nut 6

3. Wrench 13

1. Switch lever