4.2 VENTILATION

The area where the boiler is installed must always be suppplied with fresh air by using a

window or a duct. In order for a boiler to burn safely and efficiently, fresh air is required.

Otherwise once the burning starts, the oxygen level will drop causing the burning to be

inefficient. In turn, this will result in formation of soot in the boiler and chimney and will

require frequent cleaning.

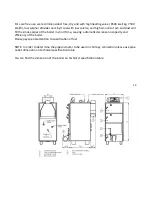

4.3 CHIMNEY

The chimney that will be connected to the boiler must be private. The chimney must be

connected to provide minimum draught. A boiler without chimney connection should not be

operated.

Chimney connection pipe and pipe systematic should be installed and checked by authorized

people only. May we remind you that the biggest factor in boiler efficiency is chimney design

and draught.

Proper chimney connection pipe should not smaller than the boilers chimney diameter, vertical

length must not be shorter than 60 cm and longer than 2 meters and pipe must be connected to

the chimney with minimum 10 degree of angle.

We suggest not to use enamel stove pipes as it creates tar in chimney connection pipe or

chimney system.

In case of an elbow use in chimney connection, the elbows must be round with a wide angle.

Quantity of an angle must be minimum 2 pieces.

Chimney connection must be installed to allow demounting from the boiler and avoid gas

leaking.

Chimney connection pipe must not be extended to the outside and must be connected to a

pipe.

The contact of chimney connection pipe with flammable material must be avoided.

Chimney connection pipe must not be pushed inside the chimney.

The direction of the pipe should not be changed, should there is a need ,it must be positioned by

60 degrees.

The chimney must be leak proof and air transperancy from inside and outside must be avoided.

No other boiler or device must be connected to same chimney. This would decrease chimney

draught and decrease boiler efficiency.

Parallel chimneys should have no inter connection.

Summary of Contents for MKK Series

Page 1: ......

Page 5: ...3 SECTIONS OF THE BOILER...

Page 14: ...6 CONTROL PANEL...

Page 20: ...9 ELECTRIC SCHEME...

Page 23: ......