7.FIRST OPERATION OF THE BOILER AND USING

ATTENTION!

Please make sure that the boiler and system is filled with water, boiler in-out valves

are open, energy to boiler panel is 220 w and grounding line is standart.

Please flood the system with water until water comes out of warning pipe.

Please check if there is any leakage in the system.

Purge out all air from the system and add some water for decreased pressure

Please mark the value on hydrometer after air purge. This marking will be a warning data in

case of loss in water.

Before burning the boiler, make sure that all valves that are supposed to be open, especialy

boiler inlet-outlet valves are open.Next, please check if the circulation pump is properly

functioning and pumping the water to right direction.

For places with low chimney draught, fan must be cancelled until the problem is

fixed.

Gas draught of the chimney must be high. A simple way to detect this is to cover the entrance of

the chimney with a news paper and see if the paper hangs in the air or not. If the paper hangs in

the air, the draught of the chimney is suitable for the boiler.

7.1 FIRST OPERATION

High quality,with high heating vale, dust free,small particle coal must be

selected. The coal to be used in the boiler is very important as it will effect boiler efficiency, ash

quantity and burning quality.

The boilers burning chamber is capable of meeting a days coal demand. The boiler must be

burned with full fuel in first burning. Avoid adding coal to the pot during burning. However, if

necessary this quantity must be as low as possible. Otherwise, these additions will increase

smoke formation and will cause the boiler and the pipes to get dirty.

Please load fuel from the front to the back after making sure that the moving grill handle and gril

is in closed position.

Summary of Contents for MKK Series

Page 1: ......

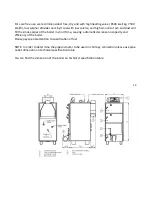

Page 5: ...3 SECTIONS OF THE BOILER...

Page 14: ...6 CONTROL PANEL...

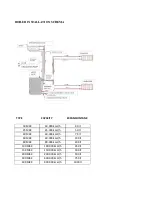

Page 20: ...9 ELECTRIC SCHEME...

Page 23: ......