7.2 WARNINGS FOR USE

ATTENTION!

Do not use the boiler without water. Please check water level each time before

burning from hydrometer.

ATTENTION !

Do not close boiler return-flow valves and circulation pump when there is burning

coal inside the boiler.

ATTENTION !

Do not open fuel feeding door frequently. In case there is a need,

shut down the fan and keep it minimum 50 cm away from the boiler.

ATTENTION !

ıf you will not use the boiler during winter, please drain the water or add anti

freeze.In case of a frost, the boiler and the pump might get damaged.

ATTENTION !

In case of an electricty cut and when the circulation pump is not functioning, the

boiler water can reach to a boiling degree, since heat transfer will not be done. In this case:

1. Please completely close the air clap on the fan’s draught opening

2. Open the by pass valves between return and flow system

3. Do not open the boiler doors

4. Do not flood any cold water to the boiler

5. Do not throw cold water on burning coal in order to put it down

ATTENTION !

If the boiler temprature cannot be controlled after doing the above, please push

the grill and lower the coal to ash tray in order to take it out of the boiler

ATTENTION !

Do not flood water to the boiler when the boiler temprature is high

Summary of Contents for MKK Series

Page 1: ......

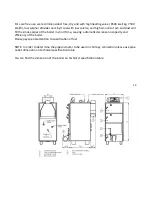

Page 5: ...3 SECTIONS OF THE BOILER...

Page 14: ...6 CONTROL PANEL...

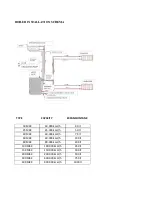

Page 20: ...9 ELECTRIC SCHEME...

Page 23: ......