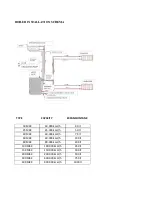

4.1 INSTALLATION AND WATER FLOOD

Please use open expansion tank for our boilers. Closed expansion tank systems may trigger

steaming of the boiler when there is an electric cut out or when the pump is not functioning.

Please connect open expansion tanks according to standarts.

No valve or similar materials must be installed on safety return or flow line of the open

expansion tank.

In order to increase safety if the pump does not function,a by pass line must be secured between

inlet and outlet spot of circulation pump as show in installation schema. The valve on by pass line

should be kept closed during normal functioning . ıf there is an electricity cut and a risk of

overheating appears, the valve must be open and the evacuation of hot water must be provided

by natural circulation. The diameter of the pipe to be used at by pass line should be the same

diameter size with the pipe used in installation at minimum.

As an extra security measure, an infinite power source may be used for electricty cut.

Please mount 3 bar security valve on the boiler for safety against over pressure in open

expansion systems.

We suggest the mounting of the pump on return line in order to protect from over heating

(steam).

All connections and valve positions must be checked after the installation of the boiler is

complete.

Operations like water flooding or evacuation must be done while the boiler is not working

and cold.

Please flood water to the system until water comes out of warning pipe. Please close the

valves when the filling is complete.

Please purge air in the system where necessary. Avoid any installation that might block air in the

system, if any doubt, please use automatic purger.

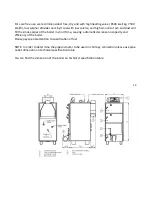

Summary of Contents for MKK Series

Page 1: ......

Page 5: ...3 SECTIONS OF THE BOILER...

Page 14: ...6 CONTROL PANEL...

Page 20: ...9 ELECTRIC SCHEME...

Page 23: ......