79

125

-

160 cc

C

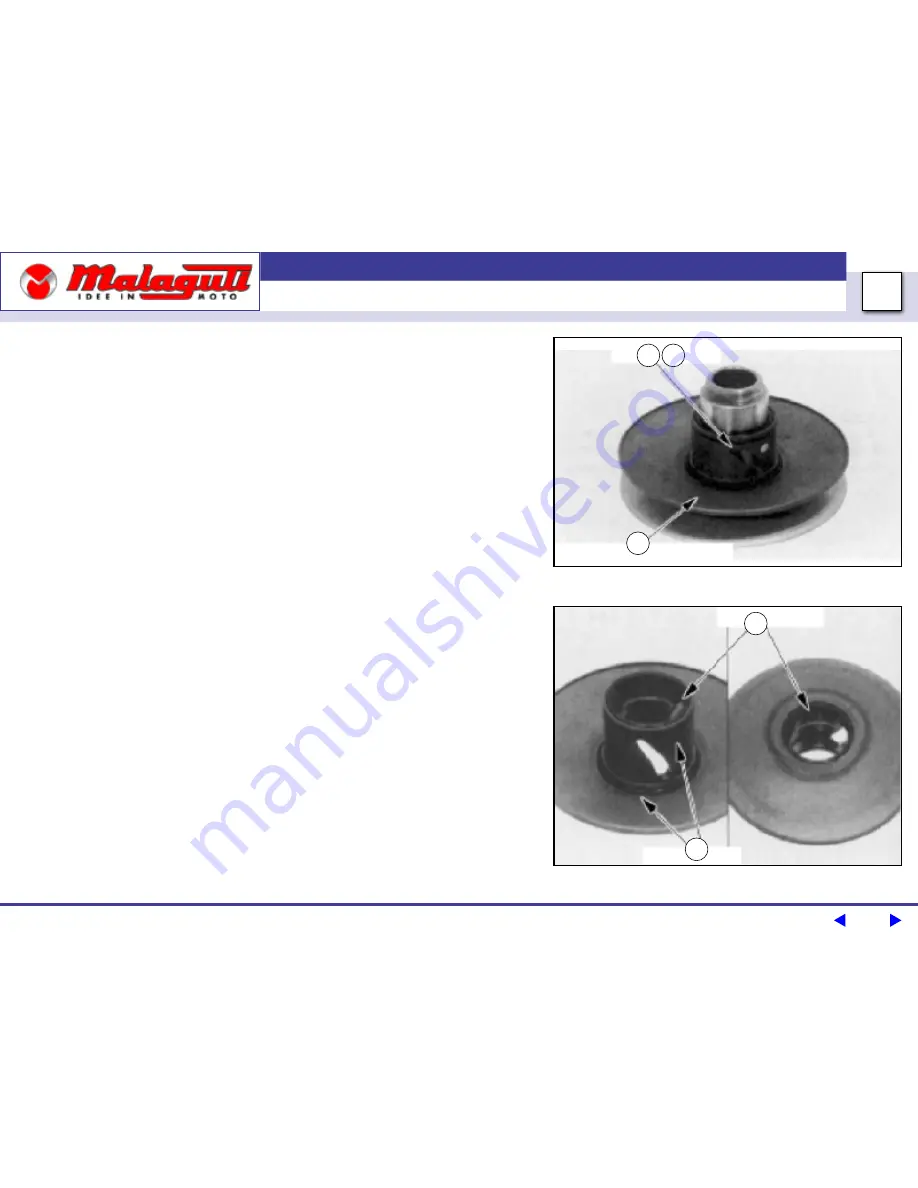

B C

E

F

G

07028173

07028174

WORKSHOP MANUAL

Remove guide pin (B) complete with roller (C); remove mobile secondary

pulley (E).

Check that guide pin (B) and roller (C) are not damaged or worn.

SPEED VARIATOR-CLUTCH UNIT

Remove oil seal (F) and O-rings (G) from mobile secondary pulley (fit new

oil seal and O-rings at time of assembly).

Check condition of fixed secondary pulley bearings.

Renew bearings if necessary