40

NO

1

NO

OK

OK

OK

1

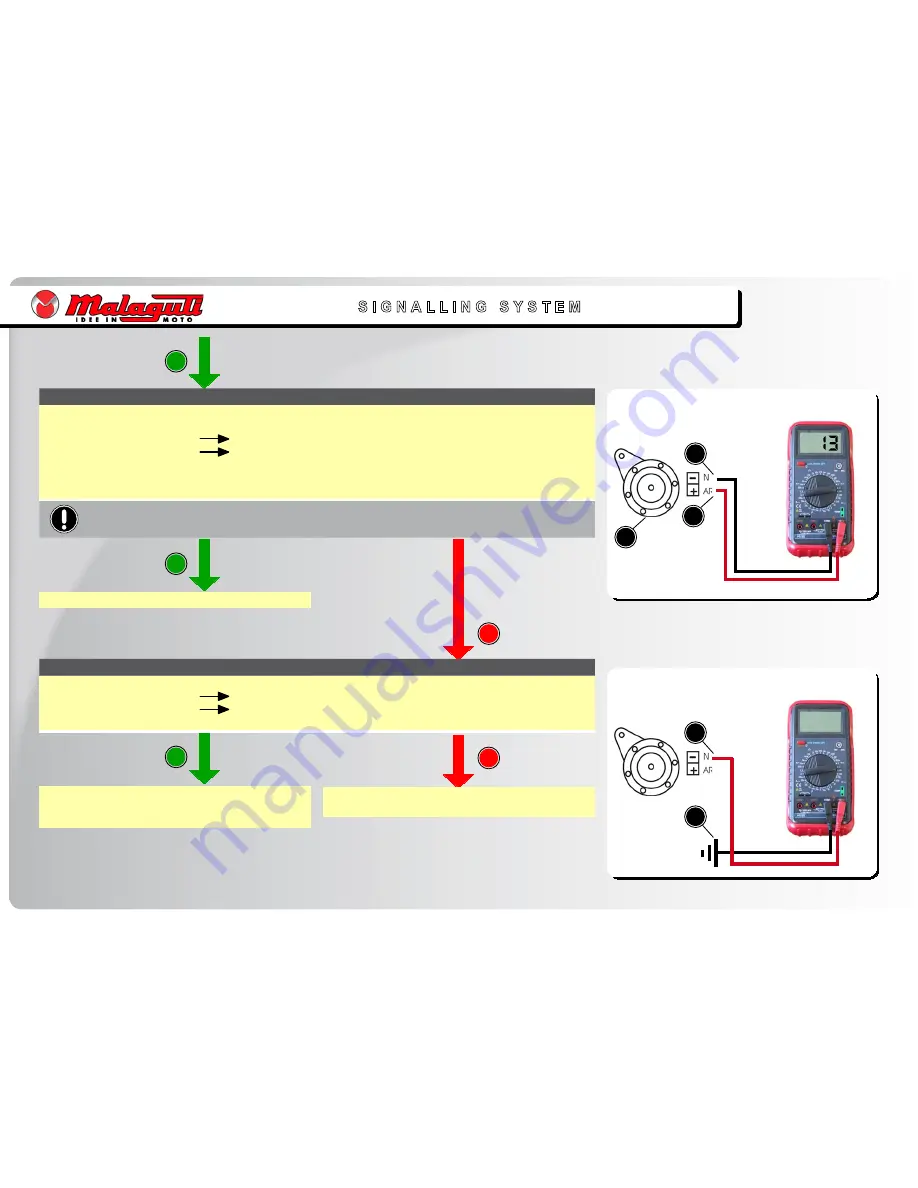

Tester (DC 0 v)

F. 27

F. 28

S I G N A L L I N G S Y S T E M

4. Check ground connection.

Connect

Tester (Ω)

as follows:

Terminal (+) of Tester

Black

cable

(1)

.

Terminal (-) of Tester

Chassis grounding

()

.

Check continuity.

•

•

•

•

Orange

cable between left hand switch and horn is

interrupted: repair it.

See “Wiring Diagram” (P. 8).

Black

cable is interrupted: repair it.

See “Wiring Diagram” (P. 8).

Tester (

Ω

)

. Horn

Disconnect horn cables

()

.

Connect

Tester (DC 0 v)

to terminals, as follows:

Terminal (+) of Tester

Orange

cable

(1)

.

Terminal (-) of Tester

Black

cable

()

.

Turn key “

ON

”.

Press “

HORN

” button.

Power measured must be

>

1 v

.

•

•

•

•

•

•

•

Never invert position of cables.

Replace horn.

Summary of Contents for Centro 50 4T

Page 1: ......