26

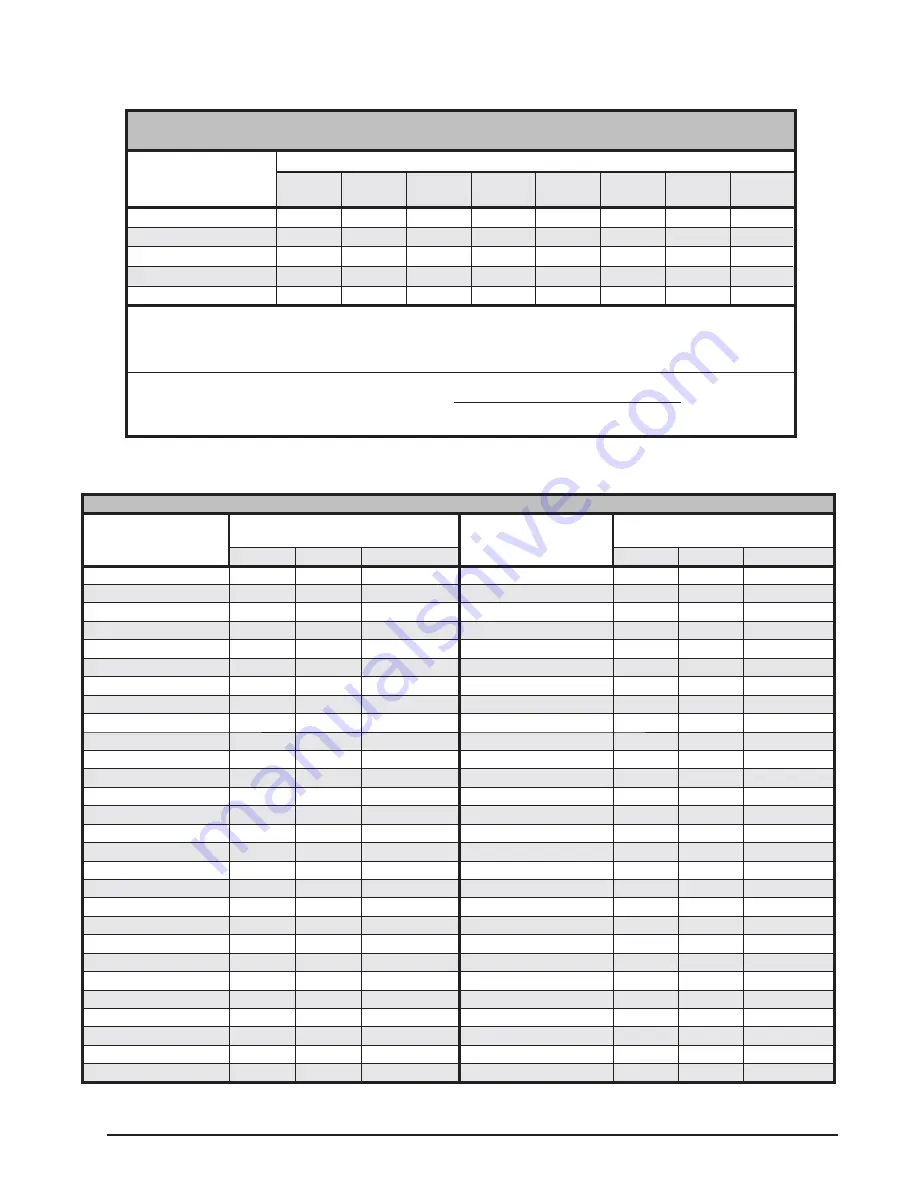

GAS FLOW RATES (CUBIC FEET PER HOUR)

TIME FOR

ONE REVOLUTION

(SECONDS)

CUBIC FEET PER REVOLUTION

OF GAS METER

TIME FOR

ONE REVOLUTION

(SECONDS)

CUBIC FEET PER REVOLUTION

OF GAS METER

1

5

10

1

5

10

10

360

1,800

3,600

66

55

273

545

12

300

1,500

3,000

68

53

265

529

14

257

1,286

2,571

70

51

257

514

16

225

1,125

2,250

72

50

250

500

18

200

1,000

2,000

74

49

243

486

20

180

900

1,800

76

47

237

474

22

164

818

1,636

78

46

231

462

24

150

750

1,500

80

45

225

450

26

138

692

1,385

82

44

220

439

28

129

643

1,286

84

43

214

429

30

120

600

1,200

86

42

209

419

32

113

563

1,125

88

41

205

409

34

106

529

1,059

90

40

200

400

36

100

500

1,000

92

39

196

391

38

95

474

947

94

38

191

383

40

90

450

900

96

38

188

375

42

86

429

857

98

37

184

367

44

82

409

818

100

36

180

360

46

78

391

783

102

35

176

353

48

75

375

750

104

35

173

346

50

72

360

720

106

34

170

340

52

69

346

692

108

33

167

333

54

67

333

667

110

33

164

327

56

64

321

643

112

32

161

321

58

62

310

621

114

32

158

316

60

60

300

600

116

31

155

310

62

58

290

581

118

31

153

305

64

56

281

563

120

30

150

300

Table 12. Gas Flow Rates

CAPACITY OF BLACK IRON GAS PIPE (CU. FT. PER HOUR)

FOR NATURAL GAS (SPECIFIC GRAVITY - 0.60)

NOMINAL BLACK

IRON PIPE

DIAMETER (IN.)

LENGTH OF PIPE RUN (FT)

10

20

30

40

50

60

70

80

1/2

130

90

75

65

55

50

45

40

3/4

280

190

150

130

115

105

95

90

1

520

350

285

245

215

195

180

170

1 1/4

1,050

730

590

500

440

400

370

350

1 1/2

1,600

1,100

890

760

670

610

NOTES

The cubic feet per hour listed above must be greater than the cubic feet per hour of gas fl ow required by the equipment.

To determine the required cubic feet per hour of gas fl ow, divide the input rate of the unit by the heating value (from gas

supplier) of the gas.

Cubic Feet Per Hour Required =

Input To Furnace (Btu/hr)

Heating Value of Gas (Btu/Cu. Ft.)

Table 11. Black Iron Gas Pipe Capacities

GAS INFORMATION