20

6.

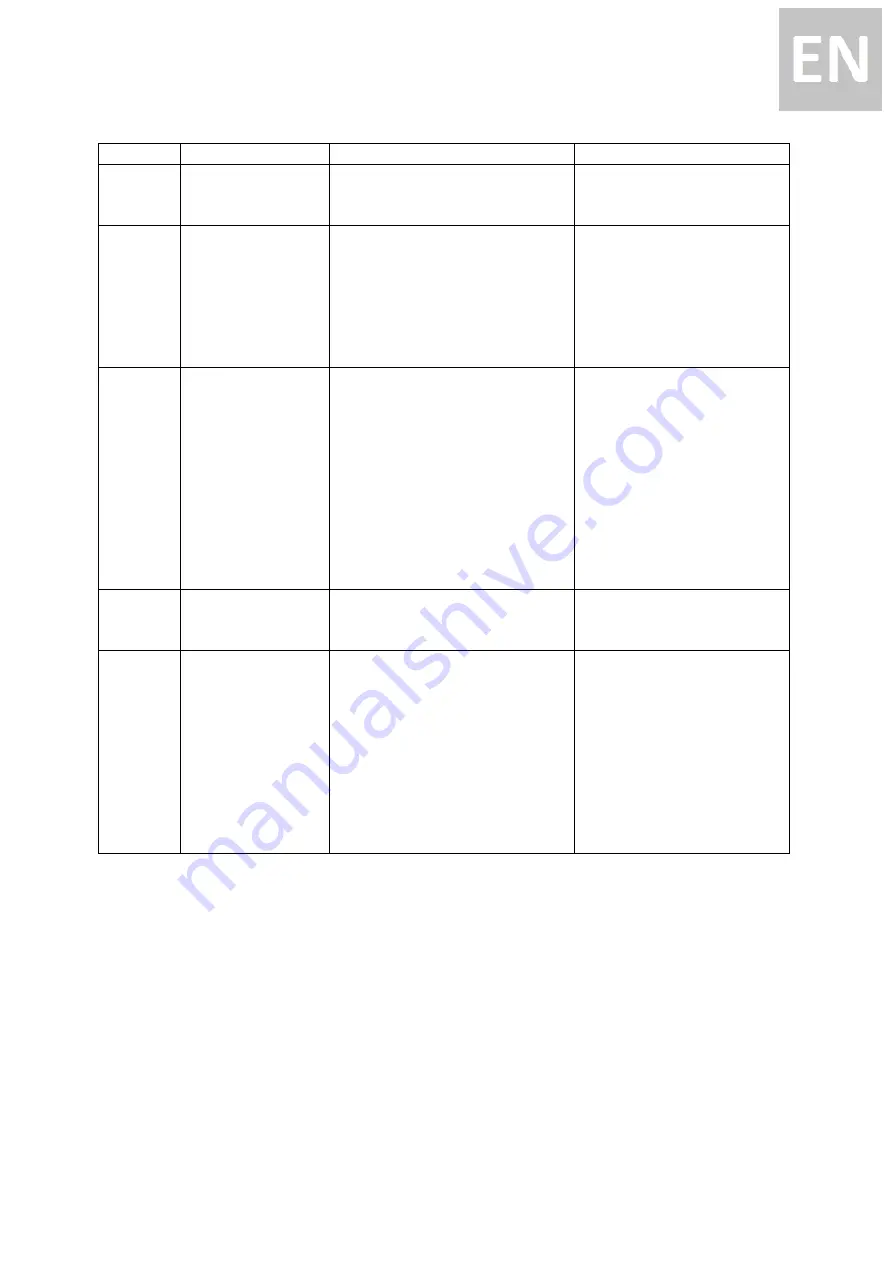

Troubleshooting

No.

Trouble

Clause

Fixing Methods

1

The forks cannot

be up at the max

height

The hydraulic oil is not enough

Pour in the oil

2

The fork cannot be

lifted up

- Without hydraulic oil

- The oil has impurities

- The nut (Part No. 59) is too high,

keep the pumping valve open.

- The air comes into the hydraulic

oil.

- Fill in the oil

- Change the oil

- Adjust the nut (Part No.59)

(see item 3.4)

- Bannish the air (see item

5.2)

3

The forks cannot

be descended

-The piston rod (Part No. 9) or

pump body (Part No. 15) is

deformed resulting from partial

loading slanting to one side or

over loading.

- The fork was kept in the high

position for long time with piston

rod bared to arise in rusting and

jamming of the rod.

- Adjusting the nut (Part No. 59) is

not the correct position.

- Replace the piston rod (Part

No. 9) or the pump body

(Part No. 15)

- Keep the fork in the lowest

position if not using, and pay

more attention to lubricate

the rod.

- Adjust the nut (Part No.59)

(see the item 3.3)

4

Leaks

- Sealing parts worn or damaged.

- Some parts creaks or worn into

small

- Replace with the new one.

- Replace with the new one.

5

The fork descends

without the release

valve worked.

- The impurities in the oil cause

the release valve to be unable to

close tight.

- Some parts of the hydraulic

system is cracked or bored.

- The air comes into the hydraulic

oil.

- Sealing parts worn or damaged.

- The adjusting nut (Part No.59) is

not the the correct position.

- Replace with the new oil.

- Inspect and replace the

waste parts.

- Bannish the air (See item

5.2)

- Replace with the new one.

- Adjust the nut (Part No.59)

(see the item 3.3)

Note! Do not attempt to repair the pallet truck unless you are trained or authorized to do so.

Inspection:

The hand pallet truck must be inspected by authorized person minimum one time per year. The

result of checking must be filled in the report.

Disposal:

After using, the pallet truck should be disposed corresponding to the law regulations. All parts should

be brought for recycling.