B 15 00 0

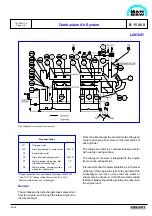

Water Mist Catcher

At outlet charge air cooler the charge air is led

through the water mist catcher. The water mist

catcher prevents condensed water (one of the major

causes of cylinder wear) from entering the combustion

chamber.

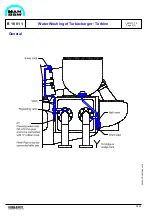

Turbocharger

The engine is as standard equipped with a high-

effeciency MAN B&W, NR/R turbocharger of the

radial type, which is located on the front end of the

engine, mounted on the top plate of the charging air

cooler housing.

Cleaning of Turbocharger

The turbocharger is fitted with an arrangement for

water washing of the turbine side, see B 16 01 1, and

water washing of the compressor side, see B 15 05

1. Soft blast cleaning on the turbine side can be fitted

as optional, see B 16 01 2.

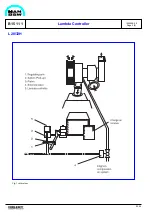

Lambda Controller

The purpose with the lambda controller is to prevent

injection of more fuel in the combustion chamber

than can be burned during a momentary load in-

crease. This is carried out by controlling the relation

between the fuel index and the charge air pressure.

The lambda controller has the following advantages:

–

Reduction of visible smoke in case of sudden

momentary load increases.

–

Improved load ability.

–

Less fouling of the engines exhaust gas ways.

Combustion Air System

L28/32H

99.48

1613523-1.4

Page 2 (2)

–

Limitating of fuel oil index during starting

procedure.

The above states that the working conditions are

improved under difficult circumstances and that the

maintenance expenses for an engine, working with

many and major load changes, will be reduced.

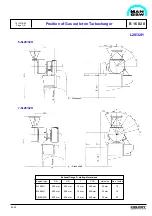

Optionals

Besides the standard components, the following

standard optionals can be built-on:

Pressure alarm low

–

PAL 35 Charge air, surplus air inlet

Pressure differential alarm low

–

PDAL 31-62, charge air and exhaust gas

Pressure transmitting

–

PT 31

Charge air, outlet from cooler

Temperature alarm high

–

TAH 31 Charge air, outlet from cooler

Temperature element

–

TE 31

Charge air, outlet from cooler

–

TE 60

Exhaust gas, outlet cylinder

–

TE 61

Exhaust gas, outlet turbocharger

–

TE 62

Exhaust gas, inlet turbocharger

Temperature indicating

–

TI 60

Exhaust gas, outlet cylinder

–

TI 61

Exhaust gas, outlet turbocharger

–

TI 62

Exhaust gas, inlet turbocharger

Data

For charge air heat dissipation and exhaust gas

data, see D 10 05 0 "List of Capacities".

Set points and operating levels for temperature and

pressure are stated in B 19 00 0 "Operating Data and

Set Points".

Summary of Contents for L28/32H

Page 4: ......

Page 5: ...Introduction I 00...

Page 6: ......

Page 8: ......

Page 10: ......

Page 11: ...Designation of Cylinders In Line 98 19 1607568 0 1 Page 1 1 I 00 15 0...

Page 12: ......

Page 18: ......

Page 19: ...General information D 10...

Page 20: ......

Page 22: ......

Page 24: ......

Page 26: ......

Page 30: ......

Page 32: ......

Page 34: ......

Page 36: ......

Page 37: ...Basic Diesel Engine B 10...

Page 38: ......

Page 44: ......

Page 45: ...99 40 B 10 01 1 L28 32H Cross Section 1607528 5 2 Page 1 1...

Page 46: ......

Page 48: ......

Page 50: ......

Page 52: ......

Page 54: ......

Page 58: ......

Page 59: ...1607566 7 1 Page 1 1 Engine Rotation Clockwise B 10 11 1 General 98 18...

Page 60: ......

Page 61: ...Fuel Oil System B 11...

Page 62: ......

Page 68: ......

Page 72: ......

Page 74: ......

Page 76: ......

Page 79: ...Lubrication Oil System B 12...

Page 80: ......

Page 86: ......

Page 88: ......

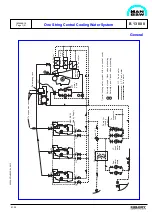

Page 91: ...Cooling Water System B 13...

Page 92: ......

Page 98: ......

Page 106: ......

Page 108: ......

Page 112: ......

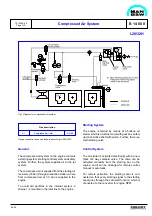

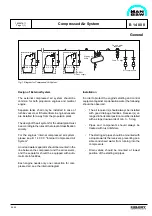

Page 113: ...Compressed Air System B 14...

Page 114: ......

Page 118: ......

Page 119: ...Combustion Air System B 15...

Page 120: ......

Page 124: ......

Page 126: ...Fig 1 Jet system 1639456 5 0 Page 2 2 Lambda Controller 93 44 L28 32H B 15 11 1...

Page 127: ...Exhaust Gas System B 16...

Page 128: ......

Page 136: ......

Page 140: ......

Page 142: ......

Page 144: ......

Page 146: ......

Page 147: ...Speed Control System B 17...

Page 148: ......

Page 150: ......

Page 152: ......

Page 153: ...Monitoring Equipment B 18...

Page 154: ......

Page 156: ......

Page 158: ......

Page 159: ...Safety and Control System B 19...

Page 160: ......

Page 164: ......

Page 166: ......

Page 177: ...Foundation B 20...

Page 178: ......

Page 180: ......

Page 183: ...Test running B 21...

Page 184: ......

Page 186: ......

Page 187: ...Spare Parts E 23...

Page 188: ......

Page 190: ......

Page 191: ...99 35 1607521 2 6 Page 1 1 Recommended Wearing Parts E 23 04 0 L28 32H...

Page 192: ......

Page 195: ...Tools P 24...

Page 196: ......

Page 200: ......

Page 202: ......

Page 203: ...Preservation and Packing B 25...

Page 204: ......

Page 206: ......

Page 208: ......

Page 210: ......

Page 211: ...Alternator G 50...

Page 212: ......

Page 216: ......

Page 218: ......