99.45

L28/32H

1613538-7.3

Page 2 (3)

Information from the Alternator supplier

G 50 02 8

Project Information should as a minimum contain the

following documentation:

1.

General description of alternator.

2.

"outline" drawing

Following information is required in order to be able to

work out drawings for base frame and general arran-

gement of GenSet.

Side view and view of driving end with all main

dimensions, i.e. length, width, height, foot position,

foot width, shaft height, etc. as well as all the

dimensions of the alternator's coupling flange, alt.

groove shaft pin.

As minimum all the dimensions in fig. 1 should be

stated.

Further the "outline" drawing is to include alternator

type, total weight with placement of center of gravity

in 2 directions (horizontal and vertical), direction of

revolution, terminal box position, lifting eyes venthole

position for air cooled alternators and min. overhaul

space for rotor, cooler, filter, etc.

a.

For water cooled alternators following informa-

tion is required:

-

position of connections

-

dimension of connections

-

dimensions of flange connections

-

cooling water capacity

-

cooling water temperature

-

heat dissipation

-

cooling water pressure loss across heat

exchanger

-

Amount of water in alt. cooling system

b.

For alternators with extern lubricating of

bearing(s) following information is required:

-

position of connections

-

dimensions of connections

-

dimensions of flange connections

-

required lub. oil flow

-

required lub. oil pressure

-

pressure regulator (if required/delivered)

-

oil sight glas (if required/delivered)

c.

For air cooled alternators following information

is required:

-

Max. permissible ambient inlet air temp.

3.

Rotor shaft drawing

Following information is required in order to be able to

work out torsional vibration calculations for the complete

GenSet.

The rotor shaft drawing must show all the dimensions

of the rotor shaft's lengths and diameters as well as

information about rotor parts with regard to mass

inertia moment - GD

2

or J (kgm

2

) and weight (kg).

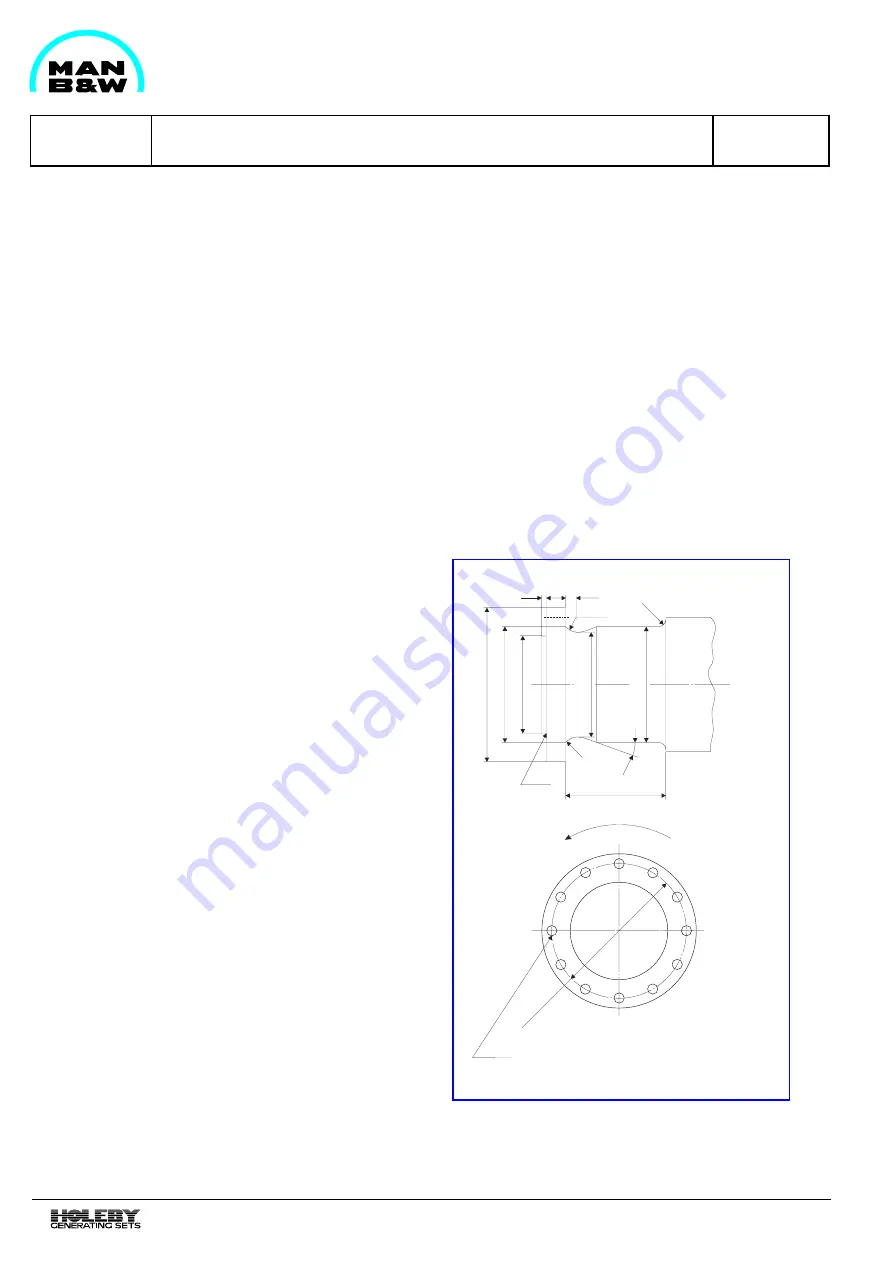

12x31.0 mm holes to be drilled acc. to MAN B&W

fig. No. V-U07B01-05-2. Holes to be reamed to-

gether with crankshaft for 32 mm fitted bolt.

50

27

Min. 230

R1

20˚

R6

R15

Max.

Ø290

Ø258

Ø250h7

-

0

0.046

Ø290

Ø400

R35

10

PCD350

Direction of rotation

Seen from fore

Fig 2 Shaft dimension for alternator, type B 16, cyl. 5 - 6 - 9

Summary of Contents for L28/32H

Page 4: ......

Page 5: ...Introduction I 00...

Page 6: ......

Page 8: ......

Page 10: ......

Page 11: ...Designation of Cylinders In Line 98 19 1607568 0 1 Page 1 1 I 00 15 0...

Page 12: ......

Page 18: ......

Page 19: ...General information D 10...

Page 20: ......

Page 22: ......

Page 24: ......

Page 26: ......

Page 30: ......

Page 32: ......

Page 34: ......

Page 36: ......

Page 37: ...Basic Diesel Engine B 10...

Page 38: ......

Page 44: ......

Page 45: ...99 40 B 10 01 1 L28 32H Cross Section 1607528 5 2 Page 1 1...

Page 46: ......

Page 48: ......

Page 50: ......

Page 52: ......

Page 54: ......

Page 58: ......

Page 59: ...1607566 7 1 Page 1 1 Engine Rotation Clockwise B 10 11 1 General 98 18...

Page 60: ......

Page 61: ...Fuel Oil System B 11...

Page 62: ......

Page 68: ......

Page 72: ......

Page 74: ......

Page 76: ......

Page 79: ...Lubrication Oil System B 12...

Page 80: ......

Page 86: ......

Page 88: ......

Page 91: ...Cooling Water System B 13...

Page 92: ......

Page 98: ......

Page 106: ......

Page 108: ......

Page 112: ......

Page 113: ...Compressed Air System B 14...

Page 114: ......

Page 118: ......

Page 119: ...Combustion Air System B 15...

Page 120: ......

Page 124: ......

Page 126: ...Fig 1 Jet system 1639456 5 0 Page 2 2 Lambda Controller 93 44 L28 32H B 15 11 1...

Page 127: ...Exhaust Gas System B 16...

Page 128: ......

Page 136: ......

Page 140: ......

Page 142: ......

Page 144: ......

Page 146: ......

Page 147: ...Speed Control System B 17...

Page 148: ......

Page 150: ......

Page 152: ......

Page 153: ...Monitoring Equipment B 18...

Page 154: ......

Page 156: ......

Page 158: ......

Page 159: ...Safety and Control System B 19...

Page 160: ......

Page 164: ......

Page 166: ......

Page 177: ...Foundation B 20...

Page 178: ......

Page 180: ......

Page 183: ...Test running B 21...

Page 184: ......

Page 186: ......

Page 187: ...Spare Parts E 23...

Page 188: ......

Page 190: ......

Page 191: ...99 35 1607521 2 6 Page 1 1 Recommended Wearing Parts E 23 04 0 L28 32H...

Page 192: ......

Page 195: ...Tools P 24...

Page 196: ......

Page 200: ......

Page 202: ......

Page 203: ...Preservation and Packing B 25...

Page 204: ......

Page 206: ......

Page 208: ......

Page 210: ......

Page 211: ...Alternator G 50...

Page 212: ......

Page 216: ......

Page 218: ......