B 10 01 1

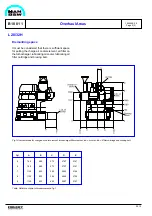

General Description

1605544-1.5

Page 4 (5)

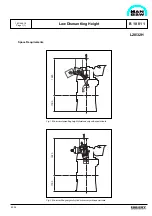

L28/32H

The lubricating oil pipes for the gear wheels are

equipped with nozzles which are adjusted to apply

the oil at the points where the gear wheels are in

mesh.

Governor

The engine speed is controlled by a hydraulic or

electric governor.

Monitoring and Control System

All media systems are equipped with thermometers

and manometers for local reading and for the most

essential pressures the manometers are together

with tachometers centralized in an engine-mounted

instrument panel.

The number of and type of parameters to have alarm

function are chosen in accordance with the re-

quirements from the classification societies.

The engine has as standard shut-down functions for

lubricating oil pressure low, cooling water tempera-

ture high and for overspeed.

Turbocharger System

The turbocharger system of the engine, which is a

constant pressure system, consists of an exhaust

gas receiver, a turbocharger, a charging air cooler

and a charging air receiver, the latter being inter-

grated in the engine frame.

The turbine wheel of the turbocharger is driven by

the engine exhaust gas, and the turbine wheel drives

the turbocharger compressor, which is mounted on

the one shaft. The compressor sucks air from the

engine room, through the air filters.

The turbocharger pumps the air through the char-

ging air cooler to the charging air receiver. From the

charging air receiver, the air flows to each cylinder,

through the inlet valves.

The charging air cooler is a compact tube-type

cooler with a large cooling surface. The cooling

96.12

water is passed twice through the cooler, the end

covers being designed with partitions which cause

the cooling water to turn.

The cooling water tubes are fixed to the tube plates

by expansion.

From the exhaust valves, the exhaust is led through

a water cooled intermediate piece to the exhaust gas

receiver where the pulsatory pressure from the indi-

vidual exhaust valves is equalized and passed to the

turbocharger as a constant pressure, and further to

the exhaust outlet and silencer arrangement.

The exhaust gas receiver is made of pipe sections,

one for each cylinder, connected to each other, by

means of compensators, to prevent excessive

stress in the pipes due to heat expansion.

In the cooled intermediate piece a thermometer for

reading the exhaust gas temperature is fitted and

there is also possibility of fitting a sensor for remote

reading.

To avoid excessive thermal loss and to ensure a

reasonably low surface temperature the exhaust

gas receiver is insulated.

Compressed Air System

The engine is started by means of a built-on air

starter.

The compressed air system comprises a main star-

ting valve, an air strainer, a remote controlled start-

ing valve and an emergency starting valve which will

make it possible to start the engine in case of a power

failure.

Fuel Oil System

The built-on fuel oil system consists of the fuel oil

filter and the fuel injection system. An engine-driven

fuel oil feed pump can be mounted as optional.

The fuel oil feed pump, which is of the gear pump

type, is mounted to the front end of the engine frame

and driven by the camshaft through a splined shaft

Summary of Contents for L28/32H

Page 4: ......

Page 5: ...Introduction I 00...

Page 6: ......

Page 8: ......

Page 10: ......

Page 11: ...Designation of Cylinders In Line 98 19 1607568 0 1 Page 1 1 I 00 15 0...

Page 12: ......

Page 18: ......

Page 19: ...General information D 10...

Page 20: ......

Page 22: ......

Page 24: ......

Page 26: ......

Page 30: ......

Page 32: ......

Page 34: ......

Page 36: ......

Page 37: ...Basic Diesel Engine B 10...

Page 38: ......

Page 44: ......

Page 45: ...99 40 B 10 01 1 L28 32H Cross Section 1607528 5 2 Page 1 1...

Page 46: ......

Page 48: ......

Page 50: ......

Page 52: ......

Page 54: ......

Page 58: ......

Page 59: ...1607566 7 1 Page 1 1 Engine Rotation Clockwise B 10 11 1 General 98 18...

Page 60: ......

Page 61: ...Fuel Oil System B 11...

Page 62: ......

Page 68: ......

Page 72: ......

Page 74: ......

Page 76: ......

Page 79: ...Lubrication Oil System B 12...

Page 80: ......

Page 86: ......

Page 88: ......

Page 91: ...Cooling Water System B 13...

Page 92: ......

Page 98: ......

Page 106: ......

Page 108: ......

Page 112: ......

Page 113: ...Compressed Air System B 14...

Page 114: ......

Page 118: ......

Page 119: ...Combustion Air System B 15...

Page 120: ......

Page 124: ......

Page 126: ...Fig 1 Jet system 1639456 5 0 Page 2 2 Lambda Controller 93 44 L28 32H B 15 11 1...

Page 127: ...Exhaust Gas System B 16...

Page 128: ......

Page 136: ......

Page 140: ......

Page 142: ......

Page 144: ......

Page 146: ......

Page 147: ...Speed Control System B 17...

Page 148: ......

Page 150: ......

Page 152: ......

Page 153: ...Monitoring Equipment B 18...

Page 154: ......

Page 156: ......

Page 158: ......

Page 159: ...Safety and Control System B 19...

Page 160: ......

Page 164: ......

Page 166: ......

Page 177: ...Foundation B 20...

Page 178: ......

Page 180: ......

Page 183: ...Test running B 21...

Page 184: ......

Page 186: ......

Page 187: ...Spare Parts E 23...

Page 188: ......

Page 190: ......

Page 191: ...99 35 1607521 2 6 Page 1 1 Recommended Wearing Parts E 23 04 0 L28 32H...

Page 192: ......

Page 195: ...Tools P 24...

Page 196: ......

Page 200: ......

Page 202: ......

Page 203: ...Preservation and Packing B 25...

Page 204: ......

Page 206: ......

Page 208: ......

Page 210: ......

Page 211: ...Alternator G 50...

Page 212: ......

Page 216: ......

Page 218: ......