08028-0D/H5250/94.08.12

It should, however, be observed that during the

running in period the lubricating oil consumption

may exceed the values stated.

Quality of Oil

Only HD lubricating oil (Delegent Lubricating Oil)

should be used, characteristic stated in "Lub. oil

spec. B 12 15 0".

B 12 00 0

L28/32H

1613544-6.4

Page 2 (4)

Internal Lubricating Oil System

99.48

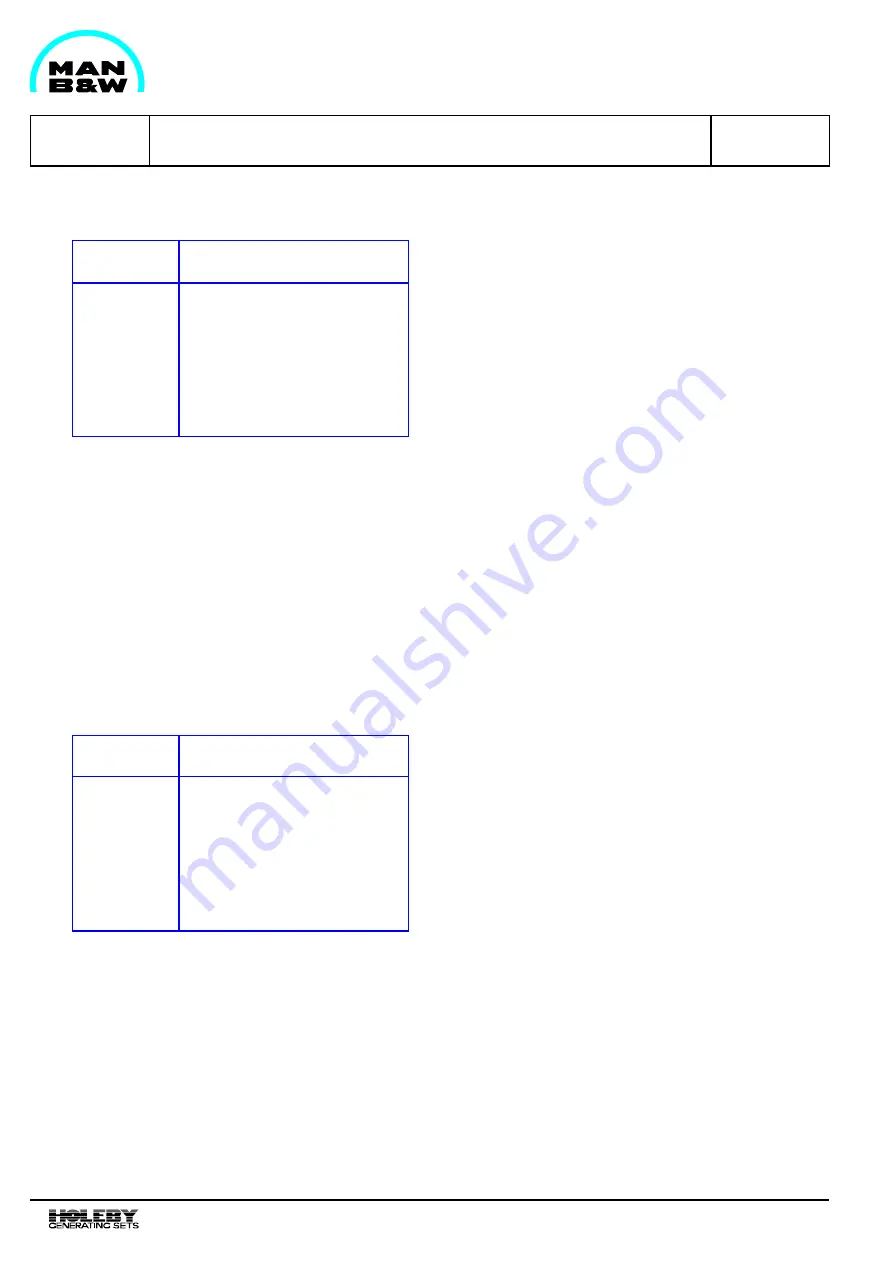

Quantities in litres for engine,

incl. cooler, filters and pipes on engine

823

963

1100

1240

1380

5

6

7

8

9

Engine type

Table 1 Quantities for starting-up the engine incl. cooler, filters and

pipes on engine.

Max. velocity recommendations for external lubrica-

ting oil pipes:

–

Pump suction side

1.0 - 1.5 m/s

–

Pump discharge side

1.5 - 2.0 m/s

Lubricating Oil Consumption

The lubricating oil consumption of MCR is:

Consumption at MCR

kg/hours

0.83

0.99

1.16

1.32

1.49

5

6

7

8

9

Engine type

Table 2 Lubricating oil consumption, tolerance ±25%.

System Flow

The lubricating oil pump draws oil from the oil sump

and presses the oil through the cooler and filter to the

main lubricating oil pipe, from where the oil is distri-

buted to the individual lubricating points. From the

lubricating points the oil returns by gravity to the oil

sump.

The main groups of components to be lubricated are:

1

–

Turbocharger

2

–

Main bearings, big-end bearing etc.

3

–

Camshaft drive

4

–

Governor drive

5

–

Rocker arms

6

–

Camshaft

1)

For priming and during operation, the turbo-

charger is connected to the lub. oil circuit of the

engine, the oil serves for bearing lubrication.

The inlet line to the turbocharger is equipped

with a fixed throttle in order to adjust the oil flow

and a non-return valve to prevent draining

during stand-still.

The non-return valve has back-pressure func-

tion requiring a pressure slightly above the

priming pressure to open in normal flow direc-

tion. In this way overflooding of the turbo-

charger is prevented during stand-still periods,

where the prelubricating pump is running.

2)

Lubricating oil for the main bearings is sup-

plied through holes drilled in the engine frame.

From the main bearings it passes through

bores in the crankshaft to the connecting rod

big-end bearings.

The connecting rods have bored channels for

supply of oil from the big-end bearings to the

small-end bearings, which has an inner cir-

cumferential groove, and a pocket for distribu-

tion of oil in the bush itself and for supply of oil

to the pin bosses and the piston cooling through

holes and channels in the piston pin.

Summary of Contents for L28/32H

Page 4: ......

Page 5: ...Introduction I 00...

Page 6: ......

Page 8: ......

Page 10: ......

Page 11: ...Designation of Cylinders In Line 98 19 1607568 0 1 Page 1 1 I 00 15 0...

Page 12: ......

Page 18: ......

Page 19: ...General information D 10...

Page 20: ......

Page 22: ......

Page 24: ......

Page 26: ......

Page 30: ......

Page 32: ......

Page 34: ......

Page 36: ......

Page 37: ...Basic Diesel Engine B 10...

Page 38: ......

Page 44: ......

Page 45: ...99 40 B 10 01 1 L28 32H Cross Section 1607528 5 2 Page 1 1...

Page 46: ......

Page 48: ......

Page 50: ......

Page 52: ......

Page 54: ......

Page 58: ......

Page 59: ...1607566 7 1 Page 1 1 Engine Rotation Clockwise B 10 11 1 General 98 18...

Page 60: ......

Page 61: ...Fuel Oil System B 11...

Page 62: ......

Page 68: ......

Page 72: ......

Page 74: ......

Page 76: ......

Page 79: ...Lubrication Oil System B 12...

Page 80: ......

Page 86: ......

Page 88: ......

Page 91: ...Cooling Water System B 13...

Page 92: ......

Page 98: ......

Page 106: ......

Page 108: ......

Page 112: ......

Page 113: ...Compressed Air System B 14...

Page 114: ......

Page 118: ......

Page 119: ...Combustion Air System B 15...

Page 120: ......

Page 124: ......

Page 126: ...Fig 1 Jet system 1639456 5 0 Page 2 2 Lambda Controller 93 44 L28 32H B 15 11 1...

Page 127: ...Exhaust Gas System B 16...

Page 128: ......

Page 136: ......

Page 140: ......

Page 142: ......

Page 144: ......

Page 146: ......

Page 147: ...Speed Control System B 17...

Page 148: ......

Page 150: ......

Page 152: ......

Page 153: ...Monitoring Equipment B 18...

Page 154: ......

Page 156: ......

Page 158: ......

Page 159: ...Safety and Control System B 19...

Page 160: ......

Page 164: ......

Page 166: ......

Page 177: ...Foundation B 20...

Page 178: ......

Page 180: ......

Page 183: ...Test running B 21...

Page 184: ......

Page 186: ......

Page 187: ...Spare Parts E 23...

Page 188: ......

Page 190: ......

Page 191: ...99 35 1607521 2 6 Page 1 1 Recommended Wearing Parts E 23 04 0 L28 32H...

Page 192: ......

Page 195: ...Tools P 24...

Page 196: ......

Page 200: ......

Page 202: ......

Page 203: ...Preservation and Packing B 25...

Page 204: ......

Page 206: ......

Page 208: ......

Page 210: ......

Page 211: ...Alternator G 50...

Page 212: ......

Page 216: ......

Page 218: ......