08028-0D\H5250\94.08.12

B 13 00 0

Freshwater System Treatment

1609571-3.4

Page 3 (5)

General

00.11

A chloride content in the cooling water higher than

the 50 ppm specified might, in exceptional cases be

tolerated. However, in that case the upper limit

specified by the individual inhibitor supplier must not

be exceed.

A clear record of all measuring results should be

kept, so that the actual condition and trend of the

system may be currently ascertained and evaluated.

A sudden or gradual degrease in pH value, or an

increase of the sulphate content, may indicate ex-

haust gas leakage. The pH value can be increased

by adding inhibtor; however, if major quantities are

necessary, the water should be replaced.

Every third month a cooling water sample should be

sent ashore for laboratory analysis, in particular to

ascertain the contents of inhibtor, sulphate, and iron,

as well as the total salinity of the water.

Cleaning and Inhibiting Procedure

The engine must not be running during the cleaning

procedure, as this may involve the risk of overhea-

ting when draining.

Degreasing

Use clean tap water for filling-up. The cooling water

in the system can be used, if it does not contain

inhibitors.

Heat the water to 60° C and circulate the water

continuously.

Drain to lowest water level in expansion tank.

Add the amount of degreasing chemical specified by

the supplier, preferably from the suction side of the

freshwater pump.

Drain to lowest water level in the expansion tank

directly afterwards.

Circulate the cleaning chemical for the period speci-

fied by the supplier.

The cooling water system must not be kept

under pressure.

Check, and repair any leaks.

Drain the system and fill up completely with clean tap

water, in order to flush out any oil or grease from the

tank.

Circulate the water for 2 hours, and drain again.

Descaling with Acid Solution

Fill up with clean tap water and heat to 70-75° C.

Dissolve the necessary dosage of acid compound in

a clean iron drum with hot water.

Fill the drum half up with water and slowly add the

acid compound, while stirring vigorously. Then fill

the drum up completely with hot water while conti-

nuing to stir (e.g. using a steam hose).

Be careful - use protective spectacles and gloves.

For engines which have been treated before the trial

trip, the lowest concentration recommended by the

supplier will normally be sufficient.

For untreated engines, a higher concentration -

depending on the condition of the cooling system -

will normally be necessary.

Drain some water from the system and add the acid

solution via the expansion tank.

The cooling water system must not be put under

pressure.

Keep the temperature of the water between 70° C

and 75° C, and circulate it constantly. The duration

of the treatment will depend on the degree of fouling.

Normally, the shortest time recommended by the

supplier will be sufficient for engines which are

treated before the trial trip. For untreated engines, a

longer time must be reckoned with. Check every

hour, for example with pH-paper, that the acid in the

solution has not been used up.

Summary of Contents for L28/32H

Page 4: ......

Page 5: ...Introduction I 00...

Page 6: ......

Page 8: ......

Page 10: ......

Page 11: ...Designation of Cylinders In Line 98 19 1607568 0 1 Page 1 1 I 00 15 0...

Page 12: ......

Page 18: ......

Page 19: ...General information D 10...

Page 20: ......

Page 22: ......

Page 24: ......

Page 26: ......

Page 30: ......

Page 32: ......

Page 34: ......

Page 36: ......

Page 37: ...Basic Diesel Engine B 10...

Page 38: ......

Page 44: ......

Page 45: ...99 40 B 10 01 1 L28 32H Cross Section 1607528 5 2 Page 1 1...

Page 46: ......

Page 48: ......

Page 50: ......

Page 52: ......

Page 54: ......

Page 58: ......

Page 59: ...1607566 7 1 Page 1 1 Engine Rotation Clockwise B 10 11 1 General 98 18...

Page 60: ......

Page 61: ...Fuel Oil System B 11...

Page 62: ......

Page 68: ......

Page 72: ......

Page 74: ......

Page 76: ......

Page 79: ...Lubrication Oil System B 12...

Page 80: ......

Page 86: ......

Page 88: ......

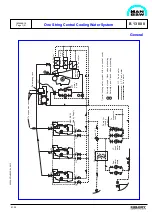

Page 91: ...Cooling Water System B 13...

Page 92: ......

Page 98: ......

Page 106: ......

Page 108: ......

Page 112: ......

Page 113: ...Compressed Air System B 14...

Page 114: ......

Page 118: ......

Page 119: ...Combustion Air System B 15...

Page 120: ......

Page 124: ......

Page 126: ...Fig 1 Jet system 1639456 5 0 Page 2 2 Lambda Controller 93 44 L28 32H B 15 11 1...

Page 127: ...Exhaust Gas System B 16...

Page 128: ......

Page 136: ......

Page 140: ......

Page 142: ......

Page 144: ......

Page 146: ......

Page 147: ...Speed Control System B 17...

Page 148: ......

Page 150: ......

Page 152: ......

Page 153: ...Monitoring Equipment B 18...

Page 154: ......

Page 156: ......

Page 158: ......

Page 159: ...Safety and Control System B 19...

Page 160: ......

Page 164: ......

Page 166: ......

Page 177: ...Foundation B 20...

Page 178: ......

Page 180: ......

Page 183: ...Test running B 21...

Page 184: ......

Page 186: ......

Page 187: ...Spare Parts E 23...

Page 188: ......

Page 190: ......

Page 191: ...99 35 1607521 2 6 Page 1 1 Recommended Wearing Parts E 23 04 0 L28 32H...

Page 192: ......

Page 195: ...Tools P 24...

Page 196: ......

Page 200: ......

Page 202: ......

Page 203: ...Preservation and Packing B 25...

Page 204: ......

Page 206: ......

Page 208: ......

Page 210: ......

Page 211: ...Alternator G 50...

Page 212: ......

Page 216: ......

Page 218: ......