MAN B&W

6.04

Page 5 of 12

MAN Diesel

MAN B&W S50MC/MC-C-TII, S46MC-C-TII, S42MC-TII,

S40MC-C-TII, S35MC/MC-C-TII, L35MC-TII, S26MC-TII

198 71 42-2.0

Freshwater Generator

If a freshwater generator is installed and is utilis-

ing the heat in the jacket water cooling system,

it should be noted that the actual available heat

in the jacket cooling water system is

lower than

indicated by the heat dissipation figures valid for

nominal MCR (L

1

) given in the List of Capacities.

This is because the latter figures are used for

dimensioning the jacket water cooler and hence

incorporate a safety margin which can be needed

when the engine is operating under conditions

such as, e.g. overload. Normally, this margin is

10% at nominal MCR.

Calculation Method

For a derated diesel engine, i.e. an engine having

a specified MCR (M) equal to optimising point (O)

different from L

1

, the relative jacket water heat dis-

sipation for point M and O may be found, as previ-

ously described, by means of Fig. 6.04.02.

At part load operation, lower than optimising

power, the actual jacket water heat dissipation will

be reduced according to the curves for fixed pitch

propeller (FPP) or for constant speed, controllable

pitch propeller (CPP), respectively, in Fig. 6.04.04.

With reference to the above, the heat actually

available for a derated diesel engine may then be

found as follows:

1.

Engine power equal to specified MCR

power M (equal to optimising point O).

For specified MCR (M) = optimising power

(O), the diagram Fig. 6.04.02 is to be used,

i.e. giving the percentage correction factor

‘Q

jw%

’ and hence for optimising power P

O

:

Q

jw,O

= Q

jw,L1

x

Q

jw%

___

100

x 0.9 (0.88)

[1]

2.

Engine power lower than optimising power.

For powers lower than the optimising power,

the value Q

jw,O

found for point O by means of

the above equation [1] is to be multiplied by

the correction factor k

p

found in Fig. 6.04.04

and hence

Q

jw

= Q

jw,O

x k

p

15%/0%

[2]

where

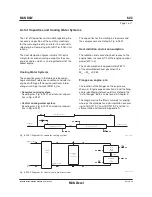

Part load correction factor for jacket

cooling water heat dissipation

Engine load, % of optimising power (O)

FPP : Fixed pitch propeller

CPP : Controllable pitch propeller, constant speed

k

p

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

0

10

20

30

40

50

60

70

80

90

100%

FPP

CPP

178 59 45-7.0

Fig. 6.04.04: Correction factor ‘kp’ for jacket cooling

water heat dissipation at part load, relative to heat dis-

sipation at optimising power

FPP : k

p

= 0.742 x

P

S

__

P

O

+ 0.258

CPP : k

p

= 0.822 x

P

S

__

P

O

+ 0.178

Q

jw

= jacket water heat dissipation

Q

jw,L1

= jacket water heat dissipation at nominal

MCR (L

1

)

Q

jw%

= percentage correction factor from

Fig. 6.04.02

Q

jw,O

= jacket water heat dissipation at optimising

power (O), found by means of equation [1]

k

p

= part load correction factor from Fig. 6.04.04

0.9 = factor for safety margin of cooler, tropical

ambient conditions

The heat dissipation is assumed to be more or less

independent of the ambient temperature conditions,

yet the safety margin/ambient condition factor of

about 0.88 instead of 0.90 will be more accurate for

ambient conditions corresponding to ISO tempera-

tures or lower. The heat dissipation tolerance from

15% to 0% stated above is based on experience.

Summary of Contents for B&W L35MC6-TII

Page 4: ......

Page 10: ......

Page 18: ......

Page 19: ...MAN B W MAN Diesel Engine Design 1 ...

Page 20: ......

Page 35: ...MAN B W MAN Diesel Engine Layout and Load Diagrams SFOC 2 ...

Page 36: ......

Page 52: ......

Page 64: ......

Page 65: ...MAN B W MAN Diesel Turbocharger Selection Exhaust Gas By pass 3 ...

Page 66: ......

Page 72: ......

Page 73: ...MAN B W MAN Diesel Electricity Production 4 ...

Page 74: ......

Page 95: ...MAN B W MAN Diesel Installation Aspects 5 ...

Page 96: ......

Page 132: ......

Page 146: ......

Page 147: ...MAN B W MAN Diesel List of Capacities Pumps Coolers Exhaust Gas 6 ...

Page 148: ......

Page 171: ...MAN B W MAN Diesel Fuel 7 ...

Page 172: ......

Page 186: ......

Page 187: ...MAN B W MAN Diesel Lubricating Oil 8 ...

Page 188: ......

Page 203: ...MAN B W MAN Diesel Cylinder Lubrication 9 ...

Page 204: ......

Page 213: ...MAN B W MAN Diesel Piston Rod Stuffing Box Drain Oil 10 ...

Page 214: ......

Page 215: ......

Page 217: ...MAN B W MAN Diesel Central Cooling Water System 11 ...

Page 218: ......

Page 223: ...MAN B W MAN Diesel Seawater Cooling System 12 ...

Page 224: ......

Page 234: ......

Page 235: ...MAN B W MAN Diesel Starting and Control Air 13 ...

Page 236: ......

Page 242: ......

Page 243: ...MAN B W MAN Diesel Scavenge Air 14 ...

Page 244: ......

Page 256: ......

Page 257: ...MAN B W MAN Diesel Exhaust Gas 15 ...

Page 258: ......

Page 272: ......

Page 273: ...MAN B W MAN Diesel Engine Control System 16 ...

Page 274: ......

Page 289: ...MAN B W MAN Diesel Vibration Aspects 17 ...

Page 290: ......

Page 304: ......

Page 305: ...MAN B W MAN Diesel Monitoring Systems and Instrumentation 18 ...

Page 306: ......

Page 328: ......

Page 329: ...MAN B W MAN Diesel Dispatch Pattern Testing Spares and Tools 19 ...

Page 330: ......

Page 360: ......

Page 361: ...MAN B W MAN Diesel Project Suppport and Documentation 20 ...

Page 362: ......

Page 371: ...MAN B W MAN Diesel Appendix A ...

Page 372: ......