MAN B&W

7.01

Page 2 of 3

MAN Diesel

MAN B&W S50MC-C, S46MC-C

198 67 37-3.1

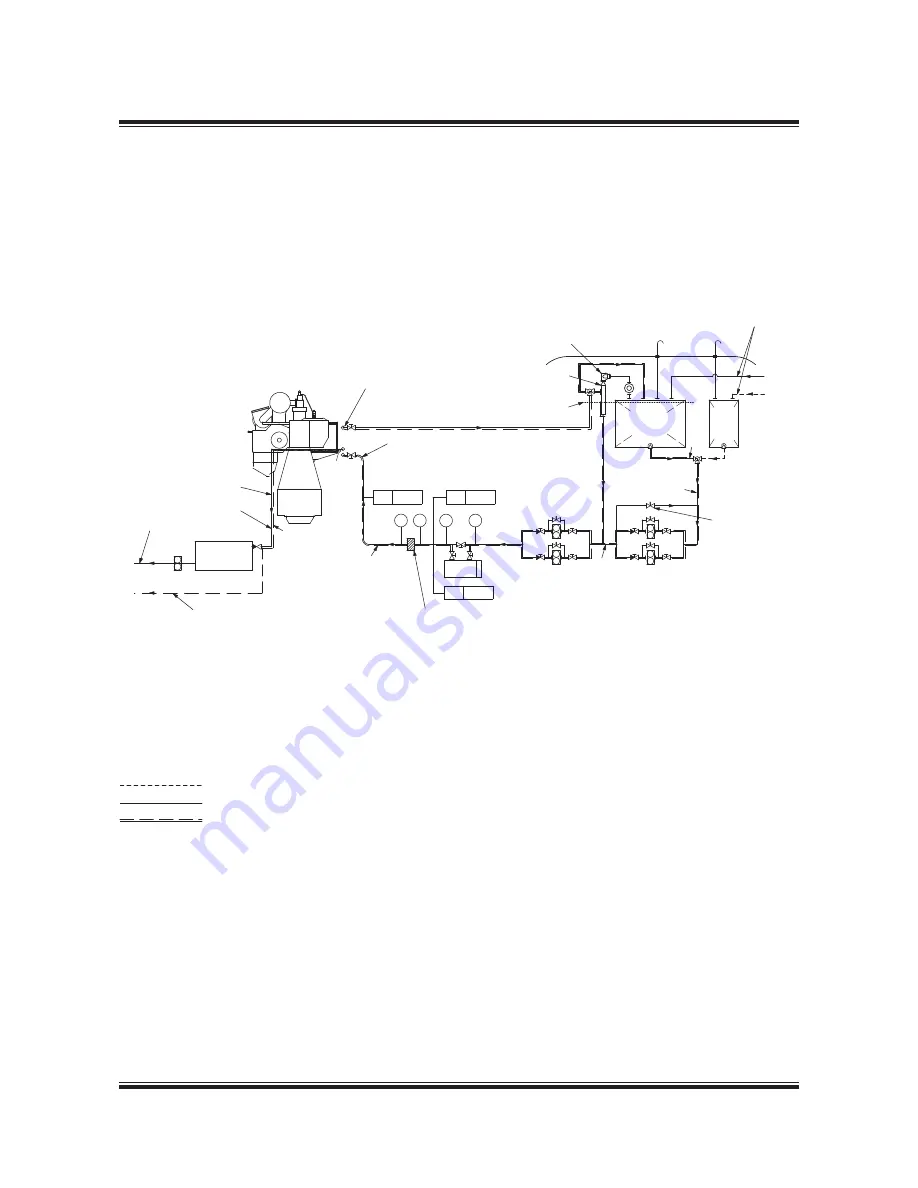

Fuel Oil System

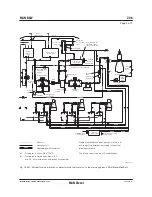

Fig. 7.01.01: Fuel oil system

078 70 06-1.1.0a

Diesel oil

Heavy fuel oil

Heated pipe with insulation

a) Tracing fuel oil lines: Max.150 °C

b) Tracing drain lines: By jacket cooling water

The letters refer to the list of ‘Counterflanges’

Deck

PI

TI

Heater

PI

TI

From centrifuges

Circulating pumps

Supply pumps

D* )

d* )

D* )

32 mm Nominal bore

Aut. deaerating valve

Top of fuel oil service tank

Venting tank

Arr. of main engine fuel oil system.

(See Fig. 7.03.01)

F

X

AF

# )

b)

a)

BD

To storage/settling tank

To freshwater cooling pump suction

To drain tank

Fuel oil

drain tank

If the fuel oil pipe to engine is made as a straight line

immediately before the engine, it will be necessary to

mount an expansion unit. If the connection is made

as indicated, with a bend immediately before the

engine, no expansion unit is required.

Full flow filter.

For filter type see engine spec.

Overflow valve

Adjusted to 4 bar

Heavy fuel oil

service tank

Diesel

oil

service

tank

TE 8005

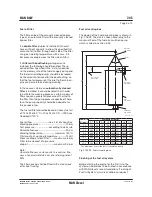

#) Approximately the following quantity of fuel oil should be treated in

the centrifuges: 0.23 l/kwh as explained in Section 7.05. The capacity of

the centrifuges to be according to manufacturer’s recommendation.

* ) D to have min. 50% larger passage area than d.

PT 8002

VT 8004

Summary of Contents for B&W S50MC-C8-TII

Page 4: ......

Page 10: ......

Page 18: ......

Page 19: ...MAN B W MAN Diesel Engine Design 1 ...

Page 20: ......

Page 35: ...MAN B W MAN Diesel Engine Layout and Load Diagrams SFOC 2 ...

Page 36: ......

Page 52: ......

Page 64: ......

Page 65: ...MAN B W MAN Diesel Turbocharger Selection Exhaust Gas By pass 3 ...

Page 66: ......

Page 72: ......

Page 73: ...MAN B W MAN Diesel Electricity Production 4 ...

Page 74: ......

Page 106: ......

Page 107: ...MAN B W MAN Diesel Installation Aspects 5 ...

Page 108: ......

Page 146: ......

Page 170: ......

Page 171: ...MAN B W MAN Diesel List of Capacities Pumps Coolers Exhaust Gas 6 ...

Page 172: ......

Page 192: ......

Page 193: ...MAN B W MAN Diesel Fuel 7 ...

Page 194: ......

Page 208: ......

Page 209: ...MAN B W MAN Diesel Lubricating Oil 8 ...

Page 210: ......

Page 223: ...MAN B W MAN Diesel Cylinder Lubrication 9 ...

Page 224: ......

Page 233: ...MAN B W MAN Diesel Piston Rod Stuffing Box Drain Oil 10 ...

Page 234: ......

Page 236: ......

Page 237: ...MAN B W MAN Diesel Central Cooling Water System 11 ...

Page 238: ......

Page 243: ...MAN B W MAN Diesel Seawater Cooling System 12 ...

Page 244: ......

Page 254: ......

Page 255: ...MAN B W MAN Diesel Starting and Control Air 13 ...

Page 256: ......

Page 262: ......

Page 263: ...MAN B W MAN Diesel Scavenge Air 14 ...

Page 264: ......

Page 276: ......

Page 277: ...MAN B W MAN Diesel Exhaust Gas 15 ...

Page 278: ......

Page 292: ......

Page 293: ...MAN B W MAN Diesel Engine Control System 16 ...

Page 294: ......

Page 309: ...MAN B W MAN Diesel Vibration Aspects 17 ...

Page 310: ......

Page 324: ......

Page 325: ...MAN B W MAN Diesel Monitoring Systems and Instrumentation 18 ...

Page 326: ......

Page 348: ......

Page 349: ...MAN B W MAN Diesel Dispatch Pattern Testing Spares and Tools 19 ...

Page 350: ......

Page 388: ......

Page 389: ...MAN B W MAN Diesel Project Suppport and Documentation 20 ...

Page 390: ......

Page 399: ...MAN B W MAN Diesel Appendix A ...

Page 400: ......