MAN B&W

2.01

Page 2 of 2

MAN Diesel

198 38 338.4

MAN B&W MC/MCC, ME/MEGI/ME-B engines

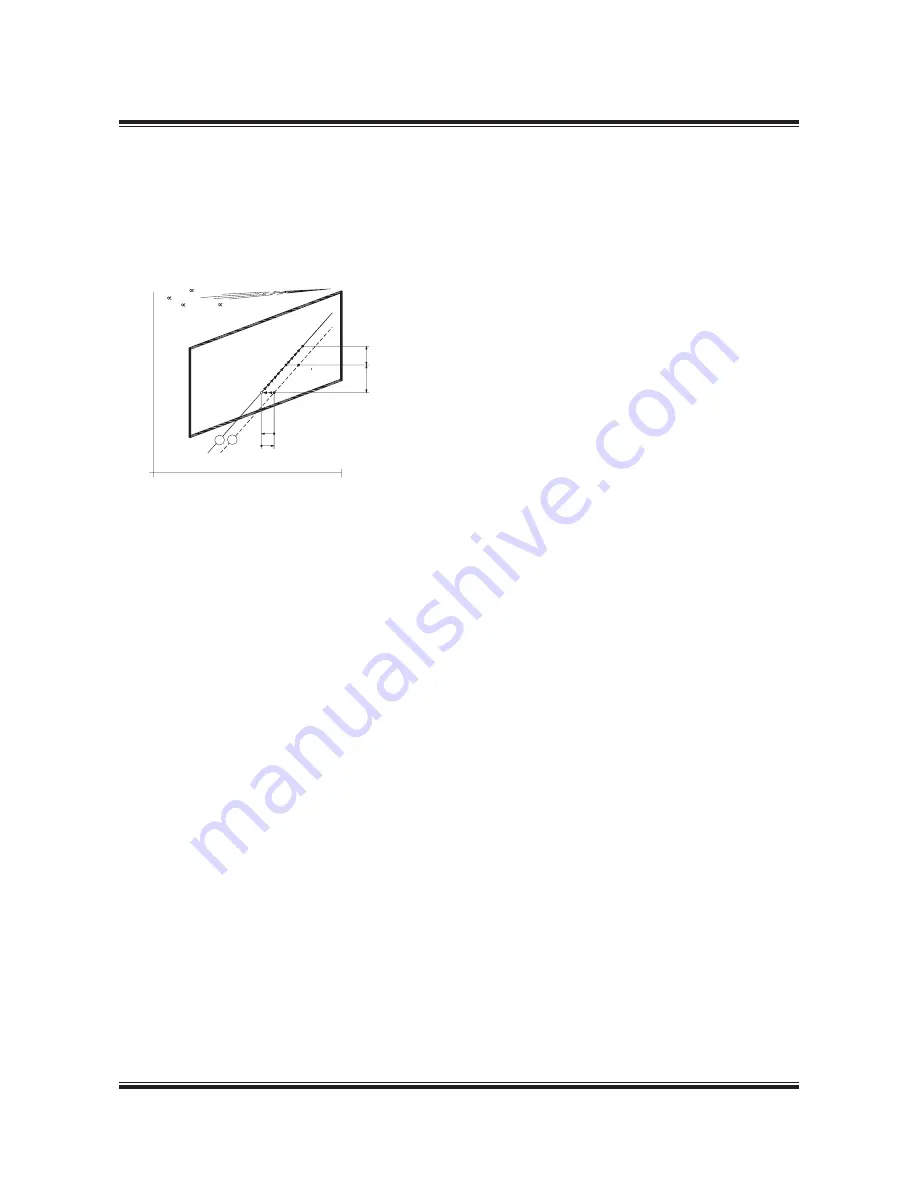

placed on the light running propeller curve 6. See

below figure. On the other hand, some shipyards,

and/or propeller manufacturers sometimes use a

propeller design point (PD) that incorporates all or

part of the socalled sea margin described below.

the socalled sea margin, which is traditionally

about 15% of the propeller design (PD) power.

Engine layout (heavy propeller)

When determining the necessary engine layout

speed that considers the influence of a heavy run-

ning propeller for operating at high extra ship resis-

tance, it is (compared to line 6) recommended to

choose a heavier propeller line 2. The propeller

curve for clean hull and calm weather line 6 may

then be said to represent a ‘light running’ (LR)

propeller.

Compared to the heavy engine layout line 2, we

recommend using a light running of

3.07.0%

for

design of the propeller.

Engine margin

Besides the sea margin, a socalled ‘engine mar-

gin’ of some 10% or 15% is frequently added. The

corresponding point is called the ‘specified MCR

for propulsion’ (MP), and refers to the fact that the

power for point SP is 10% or 15% lower than for

point MP.

Point MP is identical to the engine’s specified

MCR point (M) unless a main engine driven shaft

generator is installed. In such a case, the extra

power demand of the shaft generator must also

be considered.

Constant ship speed lines

The constant ship speed lines

∝

, are shown at

the very top of the figure. They indicate the power

required at various propeller speeds in order to

keep the same ship speed. It is assumed that, for

each ship speed, the optimum propeller diameter

is used, taking into consideration the total propul-

sion efficiency. See definition of

∝

in Section 2.02.

Note:

Light/heavy running, fouling and sea margin are

overlapping terms. Light/heavy running of the

propeller refers to hull and propeller deterioration

and heavy weather, whereas sea margin i.e. extra

power to the propeller, refers to the influence of

the wind and the sea. However, the degree of light

running must be decided upon experience from

the actual trade and hull design of the vessel.

Fig. 2.01.03: Ship propulsion running points and engine

layout

Power, % af L

1

100%

= 0,15

= 0,20

= 0,25 = 0,30

L

3

100%

L

4

L

2

Engine margin

(SP=90% of MP)

Sea margin

(15% of PD)

Engine speed, % of L

1

L

1

MP

SP

PD

HR

LR

2 6

PD

Line 2 Propulsion curve, fouled hull and heavy weather

(heavy running), recommended for engine layout

Line 6 Propulsion curve, clean hull and calm weather (light

running), for propeller layout

MP

Specified MCR for propulsion

SP

Continuous service rating for propulsion

PD

Propeller design point

HR

Heavy running

LR

Light running

Fouled hull

When the ship has sailed for some time, the hull

and propeller become fouled and the hull’s re-

sistance will increase. Consequently, the ship’s

speed will be reduced unless the engine delivers

more power to the propeller, i.e. the propeller will

be further loaded and will be heavy running (HR).

As modern vessels with a relatively high service

speed are prepared with very smooth propeller

and hull surfaces, the gradual fouling after sea

trial will increase the hull’s resistance and make

the propeller heavier running.

Sea margin and heavy weather

If, at the same time the weather is bad, with head

winds, the ship’s resistance may increase com-

pared to operating in calm weather conditions.

When determining the necessary engine power, it

is normal practice to add an extra power margin,

178 05 415.3

Summary of Contents for B&W S50MC-C8-TII

Page 4: ......

Page 10: ......

Page 18: ......

Page 19: ...MAN B W MAN Diesel Engine Design 1 ...

Page 20: ......

Page 35: ...MAN B W MAN Diesel Engine Layout and Load Diagrams SFOC 2 ...

Page 36: ......

Page 52: ......

Page 64: ......

Page 65: ...MAN B W MAN Diesel Turbocharger Selection Exhaust Gas By pass 3 ...

Page 66: ......

Page 72: ......

Page 73: ...MAN B W MAN Diesel Electricity Production 4 ...

Page 74: ......

Page 106: ......

Page 107: ...MAN B W MAN Diesel Installation Aspects 5 ...

Page 108: ......

Page 146: ......

Page 170: ......

Page 171: ...MAN B W MAN Diesel List of Capacities Pumps Coolers Exhaust Gas 6 ...

Page 172: ......

Page 192: ......

Page 193: ...MAN B W MAN Diesel Fuel 7 ...

Page 194: ......

Page 208: ......

Page 209: ...MAN B W MAN Diesel Lubricating Oil 8 ...

Page 210: ......

Page 223: ...MAN B W MAN Diesel Cylinder Lubrication 9 ...

Page 224: ......

Page 233: ...MAN B W MAN Diesel Piston Rod Stuffing Box Drain Oil 10 ...

Page 234: ......

Page 236: ......

Page 237: ...MAN B W MAN Diesel Central Cooling Water System 11 ...

Page 238: ......

Page 243: ...MAN B W MAN Diesel Seawater Cooling System 12 ...

Page 244: ......

Page 254: ......

Page 255: ...MAN B W MAN Diesel Starting and Control Air 13 ...

Page 256: ......

Page 262: ......

Page 263: ...MAN B W MAN Diesel Scavenge Air 14 ...

Page 264: ......

Page 276: ......

Page 277: ...MAN B W MAN Diesel Exhaust Gas 15 ...

Page 278: ......

Page 292: ......

Page 293: ...MAN B W MAN Diesel Engine Control System 16 ...

Page 294: ......

Page 309: ...MAN B W MAN Diesel Vibration Aspects 17 ...

Page 310: ......

Page 324: ......

Page 325: ...MAN B W MAN Diesel Monitoring Systems and Instrumentation 18 ...

Page 326: ......

Page 348: ......

Page 349: ...MAN B W MAN Diesel Dispatch Pattern Testing Spares and Tools 19 ...

Page 350: ......

Page 388: ......

Page 389: ...MAN B W MAN Diesel Project Suppport and Documentation 20 ...

Page 390: ......

Page 399: ...MAN B W MAN Diesel Appendix A ...

Page 400: ......