1

2

3

4

Removing and installing heat exchanger

52

D

Drain off coolant, see page 39

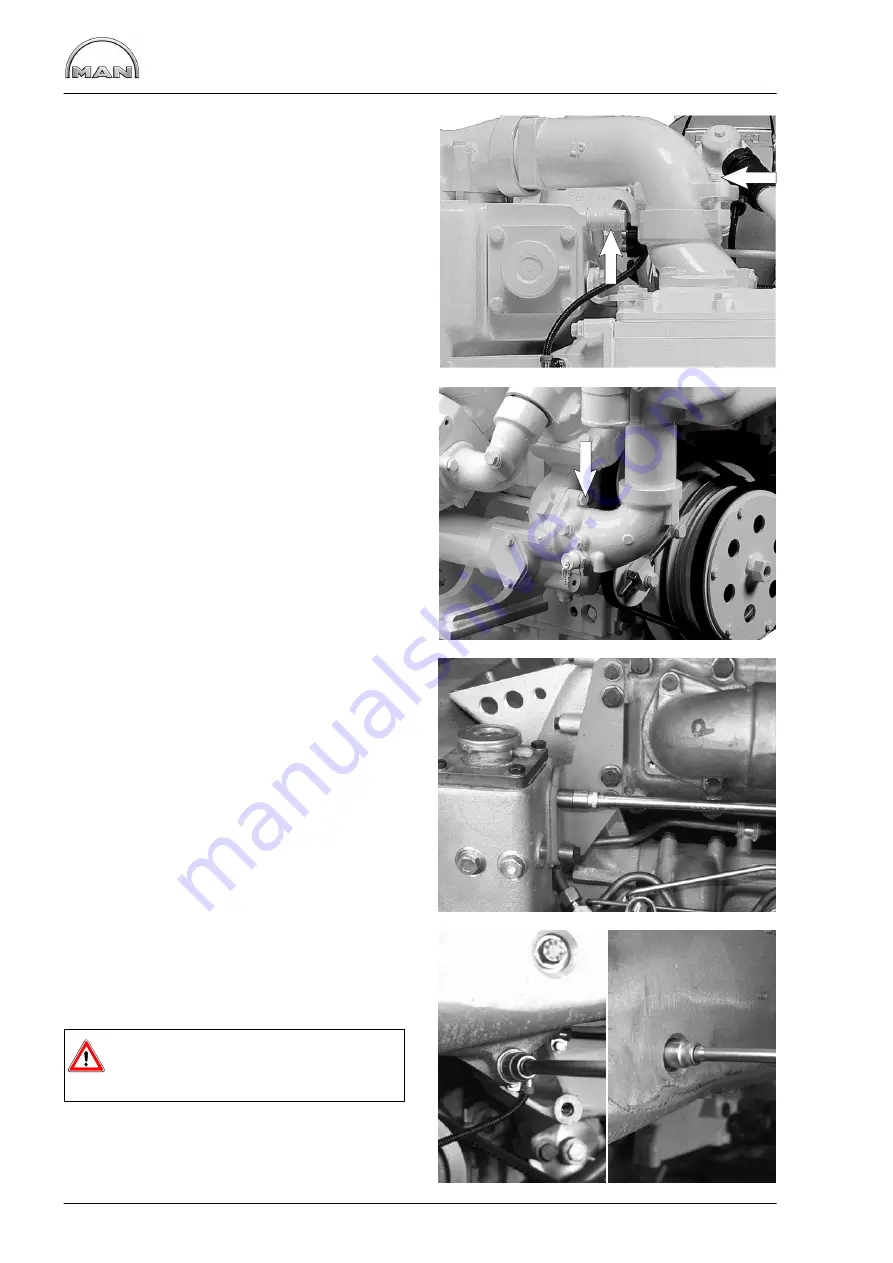

Figs. 1 and 2

Unscrew all pipe connections to the heat ex-

changer.

Fig. 3

Unscrew the mounting bolts at the brackets.

Fig. 4

Unscrew the mounting bolts on the front side of the

engine.

Take off heat exchanger.

Danger:

The heat exchanger is heavy.

Use lifting gear or work with helper.

Summary of Contents for D 2840 LE 301

Page 1: ......

Page 2: ......

Page 16: ...Notes 14...

Page 20: ...Engine views 18 Engine views D 2842 LE 301 9 10 11 12 9 8 6 5 4 3 2 1 13 14 15 16 17 18 6 7 8...

Page 150: ...Notes 148...

Page 151: ...149 Service Data...

Page 179: ...177 Special tools...

Page 180: ...Special tools 178 2 3 4 5 6 7 8 1 6 1 6 2 6 3 9 1 9 2 9 3 9...

Page 184: ...Special tools 182 21 22 25 25 2 24 25 1 26 27 1 27 2 27 20 1 19 2 19 1 20 2 19 20 28 23...

Page 186: ...Special tools 184 30 29 32 31 33...

Page 193: ......

Page 194: ......