5

6

7

8

Removing and installing crankshaft

116

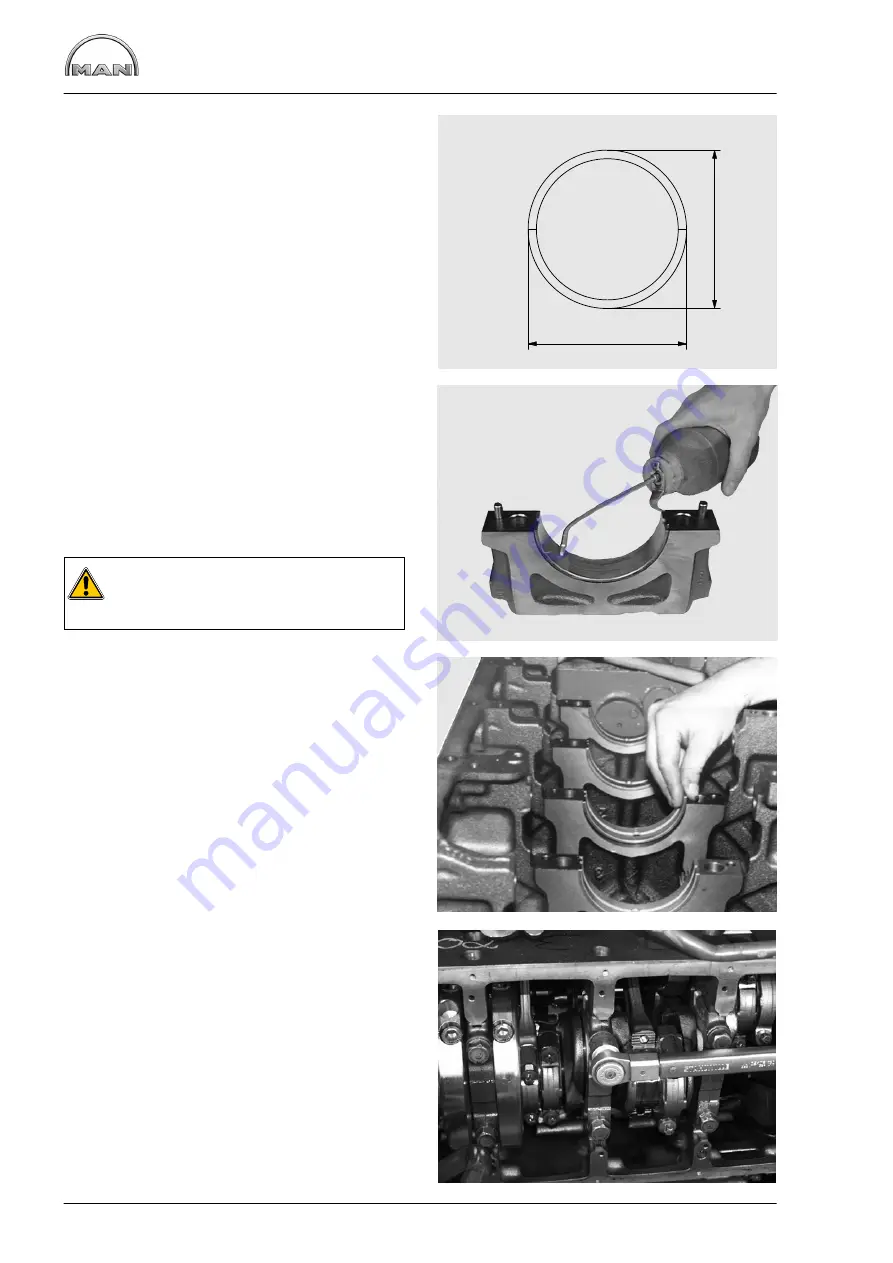

Check the spread of the bearing bushes

Fig. 5

Place the bearing shells together on a level sur-

face. Measure and note down dimensions

“A”

and

“B”

.

Spread dimension = A

−

B

Installing crankshaft

Fig. 6 and Fig. 7

Clean the oil ducts in the crankcase and in the

crankshaft with dry compressed air.

Thoroughly clean the bearing shells and journals.

Install the bearing shells in the crankcase, paying

attention to the numbering.

Caution:

If new bearing shells are used, pay atten-

tion to the corresponding repair stage.

Oil the contact surfaces of the bearing shells and

insert the crankshaft.

In doing so, note the markings of the crankshaft

and camshaft gears.

Fig. 8

Check bearing cover bolts for max. permitted

length (see “Service Data”).

Removed bolts can be reused if the max. per-

mitted length is not exceeded.

Complete the bearing covers with the associated

bearing bushes. Insert the vertical bearing cover

bolts and tighten in stages from inside to outside.

Pretightening: 300

−

330 Nm

Angle tightening: 90

_

A

B

Summary of Contents for D 2842 LE 620

Page 1: ......

Page 2: ......

Page 20: ...Engine views D 2842 LE 620 18 7 1 2 4 3 5 6 7 1 2 4 11 9 10 8...

Page 136: ...134...

Page 137: ...135 Service Data...

Page 163: ...161 Special tools...

Page 164: ...Special tools 162 1 2 3 4 5 6 7 8 9 10 11 11 1 11 2 12 12 1 12 2 13 14...

Page 166: ...Special tools 164 15 1 15 2 15 3 15 4 15 5 1 2 7 15 6 3 4 5 6 15 7...

Page 170: ...Special tools 168 3 1 4 29 5 6 2 29 30 31 32 33 34 35...

Page 172: ...Special tools 170 36 37 38 39 42 40 41 44 2 44 1 44 43 1 43 2 43 3 43 45 46...

Page 178: ...176...

Page 179: ......

Page 180: ......