9

10

11

Removing and installing pistons with conrods

120

Fig. 9

Place the conrod bearing cover in position.

Caution:

The numbers on the connecting rod bear-

ing cap and connecting rod big end must

be on one side.

Fig. 10

Screw in the conrod bearing bolts and tighten them

in stages.

Pretightening: 100

−

110 Nm

Angle tightening: 90

_

Caution:

Removed bolts must be replaced.

After inadvertent attachment of cracked

conrods and conrod bearing covers that do

not belong together, the parts must not be

reused!

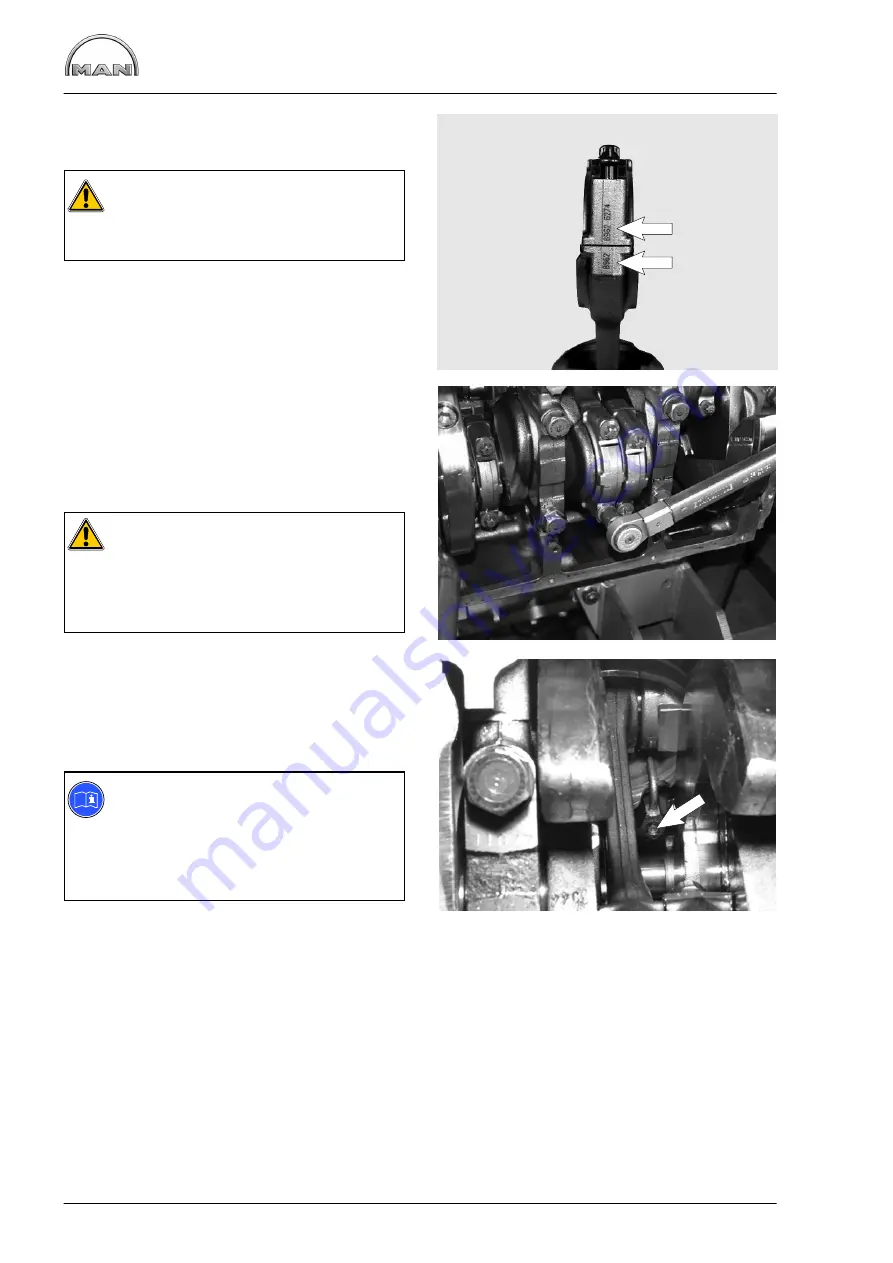

Fig. 11

Turn the engine slowly.

The conrods and oil injection nozzles (arrow) must

not collide or scuff.

Note:

As far as possible turn engine only in

direction of rotation (anti

−

clockwise as

seen when looking at the flywheel) in order

to prevent the direction of rotation of the

sea water pump impeller being reversed.

Refit in reverse order to the removal procedure all

parts previously removed.

Summary of Contents for D 2842 LE 620

Page 1: ......

Page 2: ......

Page 20: ...Engine views D 2842 LE 620 18 7 1 2 4 3 5 6 7 1 2 4 11 9 10 8...

Page 136: ...134...

Page 137: ...135 Service Data...

Page 163: ...161 Special tools...

Page 164: ...Special tools 162 1 2 3 4 5 6 7 8 9 10 11 11 1 11 2 12 12 1 12 2 13 14...

Page 166: ...Special tools 164 15 1 15 2 15 3 15 4 15 5 1 2 7 15 6 3 4 5 6 15 7...

Page 170: ...Special tools 168 3 1 4 29 5 6 2 29 30 31 32 33 34 35...

Page 172: ...Special tools 170 36 37 38 39 42 40 41 44 2 44 1 44 43 1 43 2 43 3 43 45 46...

Page 178: ...176...

Page 179: ......

Page 180: ......