12

13

14

15

Repairing coolant pump with high-temperature

and low-temperature parts

47

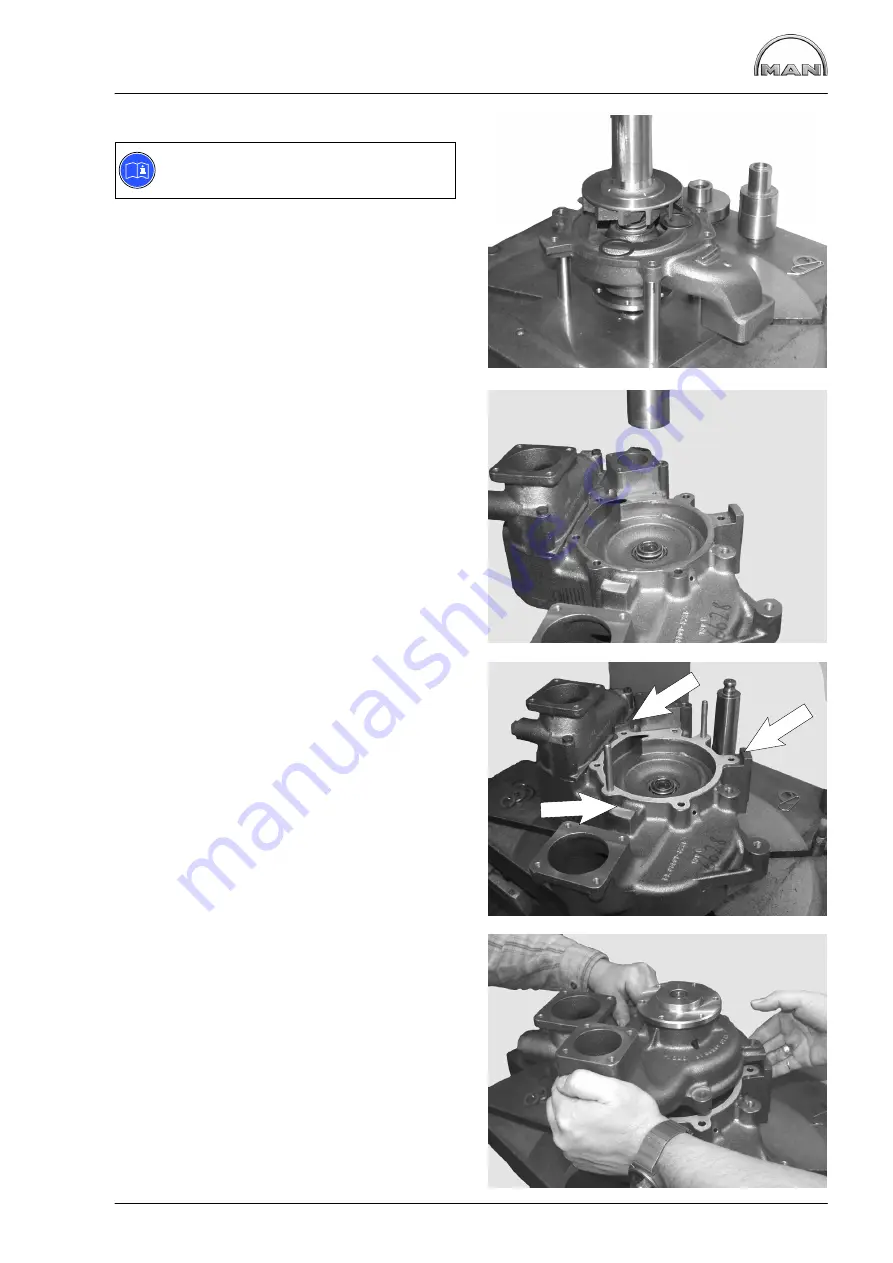

Fig. 12

Note:

Brace the bearing shaft.

Slowly press impeller on to bearing shaft to ensure

correct gap (0,5

+0,4

).

Fig. 13

Press in new mechanical seal (pos. 8) with press-

fitting sleeve (special tool) until it stops.

Observe installation note for seal on page 50.

Fig. 14

Lay coolant pump gasket on pump housing.

Fig. 15

Carefully fit low-temperature suction part to high-

temperature pump housing.

To make assembly easier insert 2 pins in opposite

sides of HT part (see Fig. 14)

Do not use force (hammer etc.) and note the 3

centring features (see arrows in Fig. 14).

Screw in bolt (Fig. 1, item 5).

Bolt LT and HT parts together with 2 bolts and nuts

on opposite sides (Fig. 1, item 4).

Summary of Contents for D 2842 LE 620

Page 1: ......

Page 2: ......

Page 20: ...Engine views D 2842 LE 620 18 7 1 2 4 3 5 6 7 1 2 4 11 9 10 8...

Page 136: ...134...

Page 137: ...135 Service Data...

Page 163: ...161 Special tools...

Page 164: ...Special tools 162 1 2 3 4 5 6 7 8 9 10 11 11 1 11 2 12 12 1 12 2 13 14...

Page 166: ...Special tools 164 15 1 15 2 15 3 15 4 15 5 1 2 7 15 6 3 4 5 6 15 7...

Page 170: ...Special tools 168 3 1 4 29 5 6 2 29 30 31 32 33 34 35...

Page 172: ...Special tools 170 36 37 38 39 42 40 41 44 2 44 1 44 43 1 43 2 43 3 43 45 46...

Page 178: ...176...

Page 179: ......

Page 180: ......