4

5

6

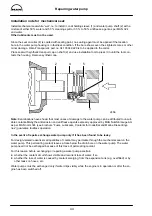

Draining and filling with coolant

38

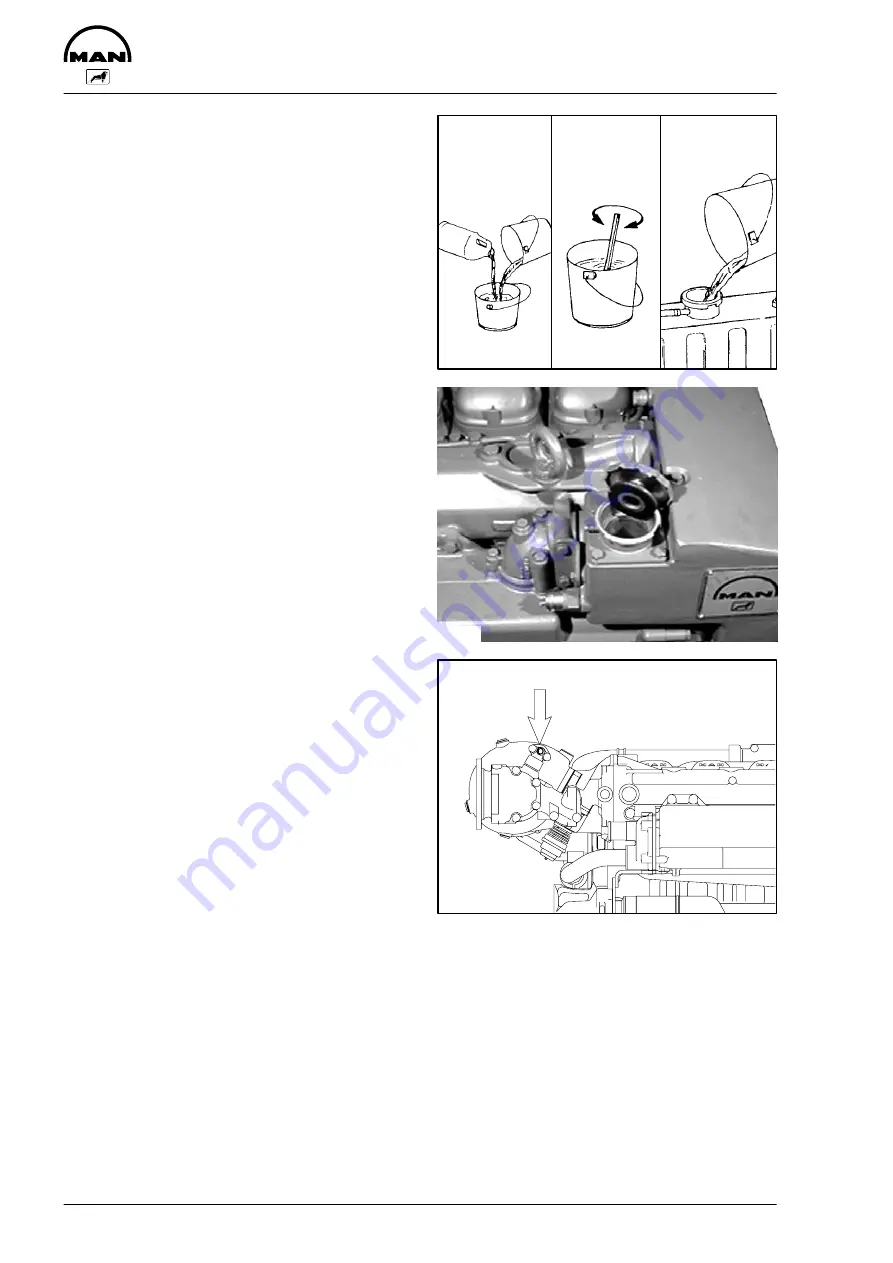

Filling up with coolant

Fig. 4

The engine’s cooling system is to be filled up with

a mixture of potable tap water and antifreeze agent

on ethylene glycol basis or anticorrosion agent.

See publication ”Fuels, Lubricants, Coolants for

Industrial and Marine Diesel Engines”.

Coolant must be added at the filler neck only.

Do not put cold coolant into an engine which is

warm from operation.

Ensure that the ratio of water to anti-freeze is cor-

rect.

Figs. 5 and 6

D

Remove cap (large cap)

D

Set heating (if fitted) to full output, open all

shut-off valves, open bleeders (if fitted)

D

Unscrew bleed screw on liquid-cooled turbo-

charger

D

Slowly fill up with coolant via filler neck on ex-

pansion tank until fluid level has reached the

lower edge of the filler neck

D

Screw in bleeder screws again and refit cap

D

Let engine run at a speed of 2,000 rpm for

approx. 5 minutes

D

Switch off engine, carefully turn cap (1) with

safety valve to first detent –let off pressure–

then carefully take off cap

2707

3415

2598

Summary of Contents for D 2866 LE 401

Page 1: ......

Page 17: ...Engine views D 2866 LE401 16...

Page 18: ...Engine views D 2866 LE401 17...

Page 19: ...Cross section of engine 18...

Page 20: ...Longitudinal section 19...

Page 124: ...123 Special tools...

Page 125: ...Special tools 124 2 3 4 5 6 7 9 1 8 6 1 6 2 6 3...

Page 129: ...Special tools 128 21 22 23 25 25 2 24 25 1 26 27 1 27 2 27 20 1 19 2 19 1 20 2 19 20...

Page 131: ...Special tools 130 29 28 30...

Page 138: ......