16

17

18

19

Repairing coolant pump with high-temperature and

low-temperature parts D 2866 LUE 605

52

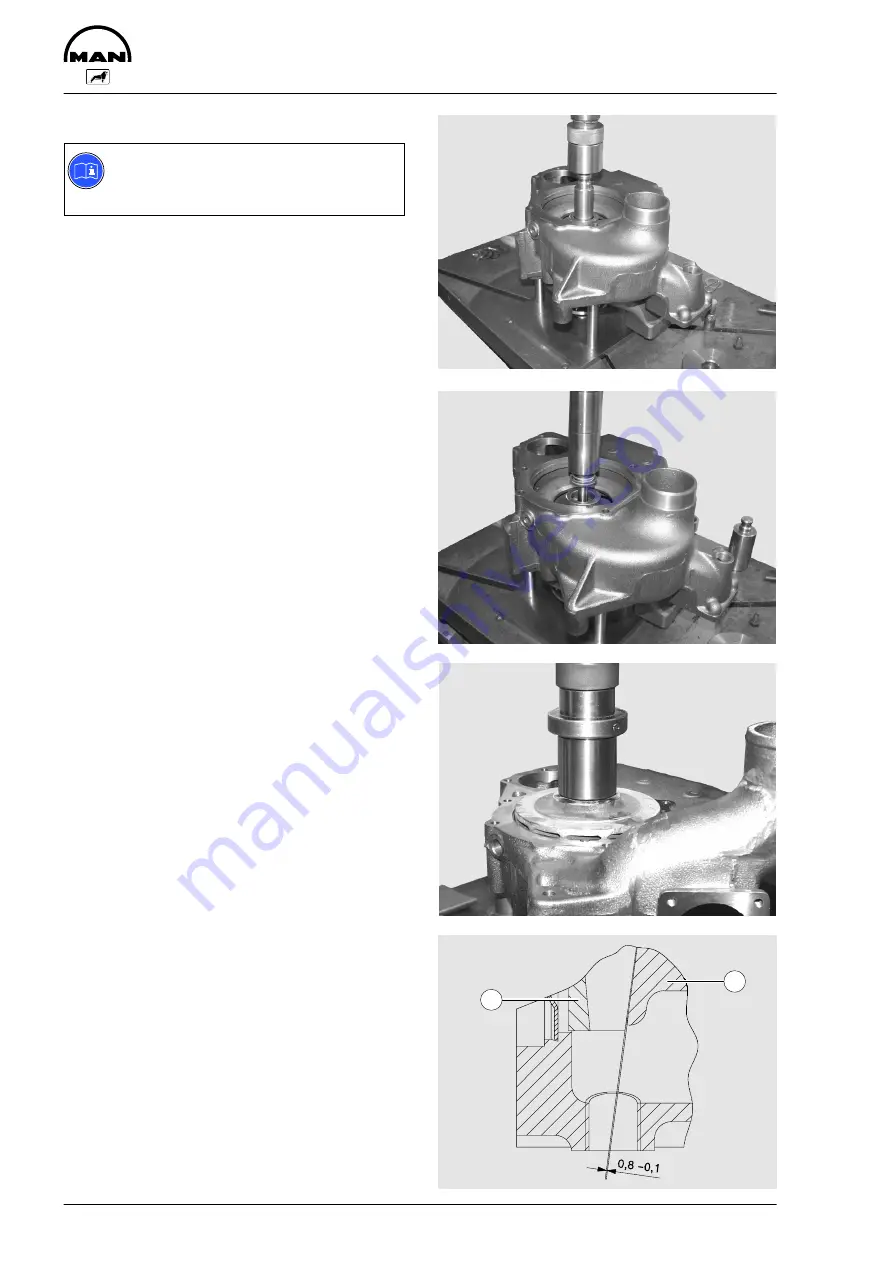

Fig. 16

Note:

For subsequent steps brace the bearing

shaft.

Press grooved ball bearing 6003 into position using

special tool.

Fig. 17

Press in new mechanical seal (pos.6) with press-

fitting sleeve (special tool) until it stops.

Observe installation note for seal on page, 47.

Fig. 18

Slowly press impeller on to bearing shaft to ensure

correct gap.

Fig. 19

For this purpose an inspection hole closed up with

a screw plug (M16x1.5) is provided on the bottom

of the water pump housing.

1 Impeller

2 Water pump housing

2

1

Summary of Contents for D 2866 LUE 605

Page 1: ......

Page 2: ......

Page 14: ...Notes 12...

Page 19: ...Memoranda 17...

Page 20: ...Engine views 18 Engine views 3 4 2 1 7 6 5 8 11 10 9...

Page 68: ...Memoranda 66...

Page 133: ...131 Service Data...

Page 157: ...155 Special tools...

Page 158: ...Special tools 156 2 3 4 5 6 7 8 1 6 1 6 2 6 3 9 1 9 2 9 3 9...

Page 162: ...Special tools 160 21 22 25 25 2 24 25 1 26 27 1 27 2 27 20 1 19 2 19 1 20 2 19 20 23 28...

Page 164: ...Special tools 162 30 31 32 1 32 32 2...

Page 167: ...Special tools 165 Pressing mandel for cap dia 62 1 mm Pressing mandel for cap dia 50 1 mm...

Page 170: ...Notes 168...

Page 173: ......

Page 174: ......