4

Replacing valve seat insert

96

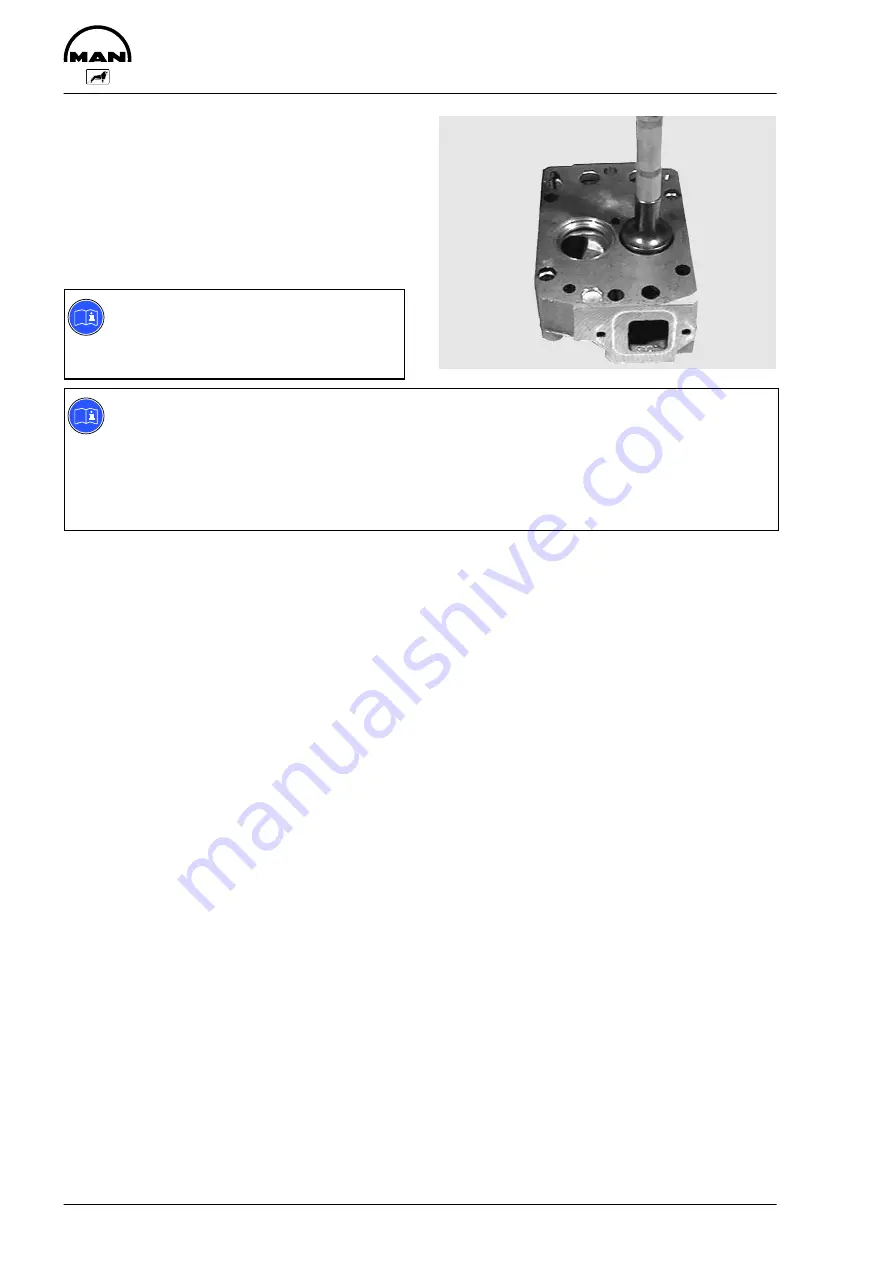

Installing valve seat insert

Fig. 4

Cool new valve seat insert down to approx. -200

°

C

and insert it into the cylinder head (at an ambient

temperature of approx. 20

°

C).

Carry out check by driving it in until the stop is re-

ached using pressing tool.

Install valve guides.

Note:

When the valve seat inserts have been

changed, the valve seats must be re-

worked.

Note:

D

After temperature equalization, machine valve seats

D

After machining, clean cylinder head and check for leaks using leak testing device

D

f the cylinder head is excessively heated (above +200

_

C, +390

_

F) the core hole covers (end

covers) loose their tightness and must be exchanged

D

To do this, clean core holes, blow out channels and press in new core hole covers with

“LOCTITE 648” and pressing mandrel

Summary of Contents for D 2866 LUE 605

Page 1: ......

Page 2: ......

Page 14: ...Notes 12...

Page 19: ...Memoranda 17...

Page 20: ...Engine views 18 Engine views 3 4 2 1 7 6 5 8 11 10 9...

Page 68: ...Memoranda 66...

Page 133: ...131 Service Data...

Page 157: ...155 Special tools...

Page 158: ...Special tools 156 2 3 4 5 6 7 8 1 6 1 6 2 6 3 9 1 9 2 9 3 9...

Page 162: ...Special tools 160 21 22 25 25 2 24 25 1 26 27 1 27 2 27 20 1 19 2 19 1 20 2 19 20 23 28...

Page 164: ...Special tools 162 30 31 32 1 32 32 2...

Page 167: ...Special tools 165 Pressing mandel for cap dia 62 1 mm Pressing mandel for cap dia 50 1 mm...

Page 170: ...Notes 168...

Page 173: ......

Page 174: ......