1

2

3

Reworking valve seat

97

Reworking valve seat

(with Mira precision valve seat machining device)

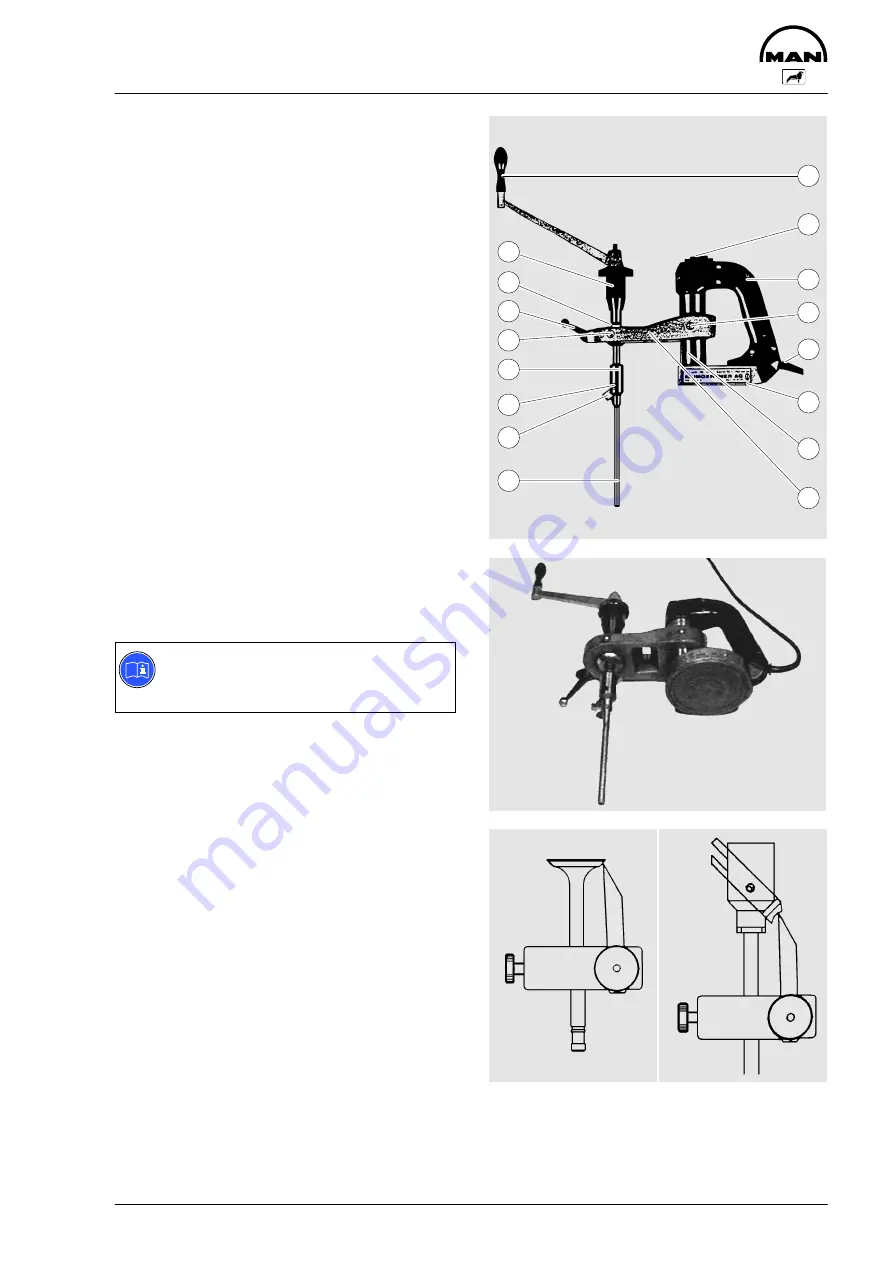

Fig. 1

1 Feed nut with mm scale

2 Guide ball

3 Jaccard lever

4 Lubricating nipple

5 Rotary head

6 Hex socket screw

7 Tool

8 Guide mandrel

9 Driving crank

10 Toggle switch

11 Handle

12 Lubricating nipple

13 Mains connection

14 Magnetic flange with coil

15 Guide pipe

16 Slewing arm

Fig. 2

Select suitable guide mandrel, screw it in with a

spanner (12 mm) and tighten it.

Note:

For extreme precision work the guide

mandrel must fit snugly.

Select and insert the tool with the corresponding

seat width and the corresponding seat angle.

Fig. 3

Set the tool with a setting gauge and tighten it with

the hex socket screw.

Insert unit with guide mandrel into the valve guide.

2

3

1

4

5

6

7

8

9

10

11

12

13

14

15

16

Summary of Contents for D 2866 LUE 605

Page 1: ......

Page 2: ......

Page 14: ...Notes 12...

Page 19: ...Memoranda 17...

Page 20: ...Engine views 18 Engine views 3 4 2 1 7 6 5 8 11 10 9...

Page 68: ...Memoranda 66...

Page 133: ...131 Service Data...

Page 157: ...155 Special tools...

Page 158: ...Special tools 156 2 3 4 5 6 7 8 1 6 1 6 2 6 3 9 1 9 2 9 3 9...

Page 162: ...Special tools 160 21 22 25 25 2 24 25 1 26 27 1 27 2 27 20 1 19 2 19 1 20 2 19 20 23 28...

Page 164: ...Special tools 162 30 31 32 1 32 32 2...

Page 167: ...Special tools 165 Pressing mandel for cap dia 62 1 mm Pressing mandel for cap dia 50 1 mm...

Page 170: ...Notes 168...

Page 173: ......

Page 174: ......